A Two-Stage Composite Large Stroke High Precision Fast Mirror

A technology of fast mirrors and large strokes, applied in optical components, instruments, optics, etc., can solve problems such as difficult to break through structure and drive, and achieve the effect of reducing the overall size and high response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

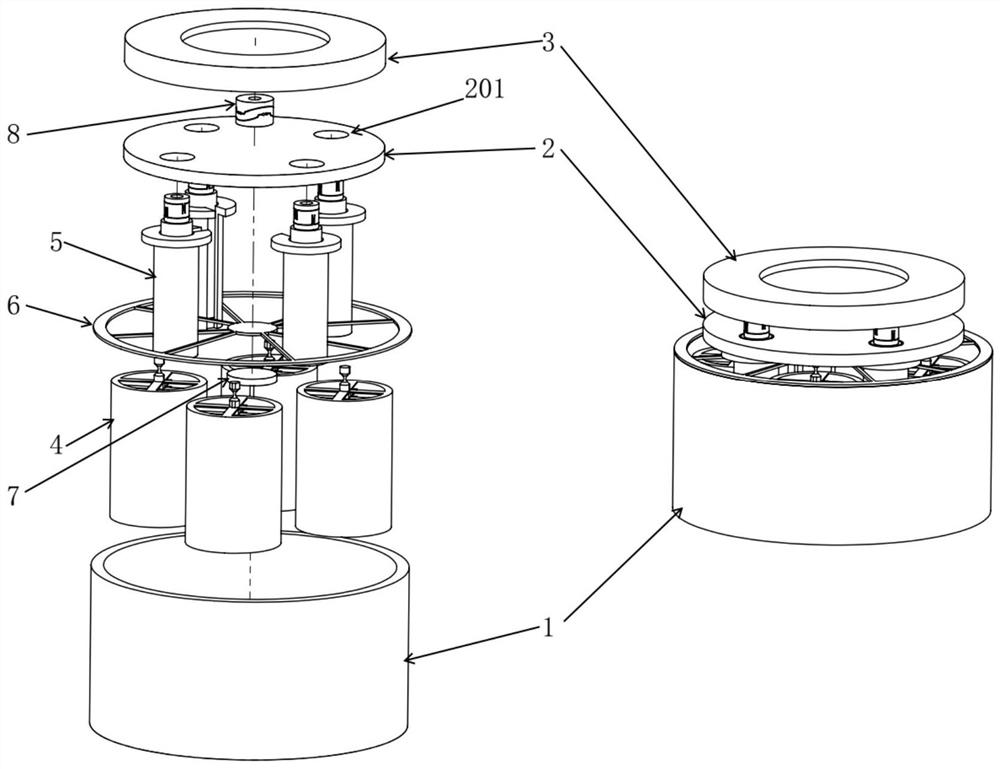

[0024] refer to figure 1 A kind of two-stage composite large-stroke high-precision fast reflector of the embodiment of the present invention shown in ~3,

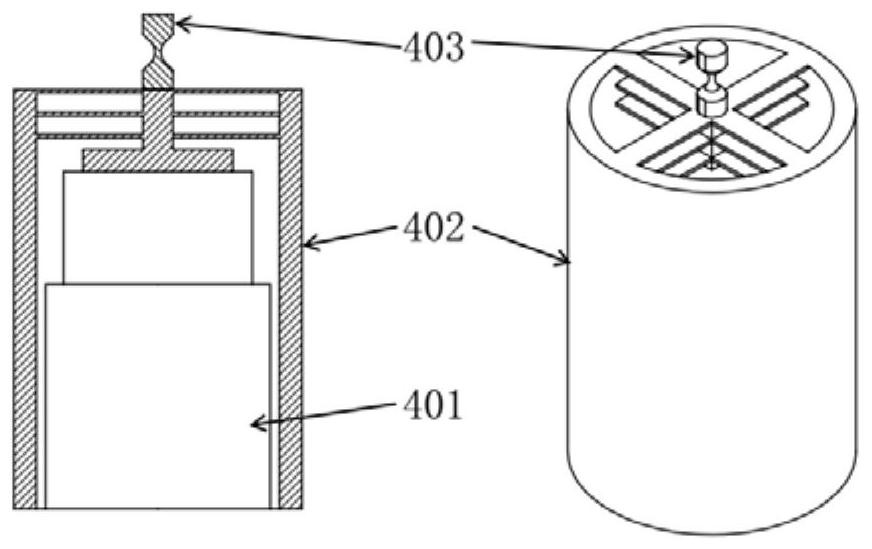

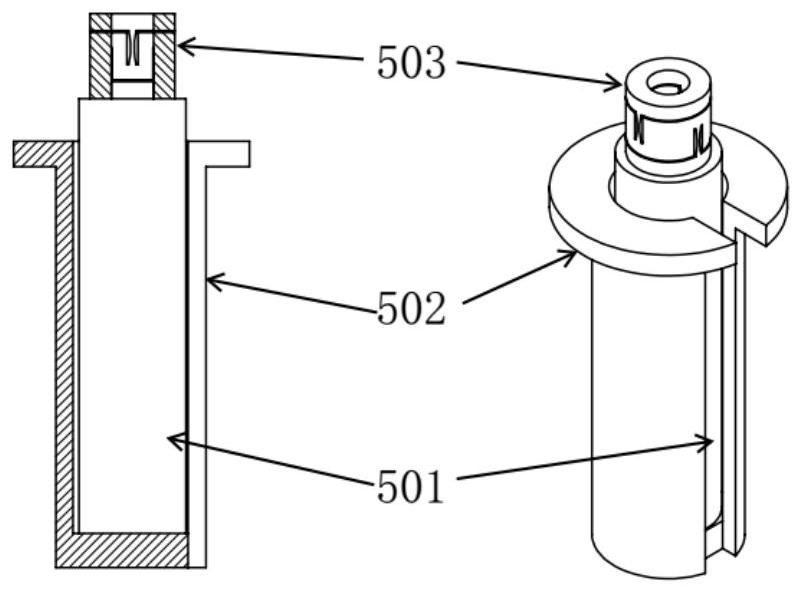

[0025] It includes a base 1, an intermediate platform 2, an output platform 3, a voice coil driving part 4, a piezoelectric driving part 5, a first flexible support 6, a second flexible support 7, and a third flexible support 8, wherein the intermediate platform 2 is set There is a through hole 201 , the voice coil driving part 4 includes a voice coil motor 401 , a flexible translation pair 402 and a first flexible hinge 403 , and the piezoelectric driving part 5 includes a piezoelectric driver 501 , a piezoelectric mounting base 502 and a second flexible hinge 503 .

[0026] Both ends of the first flexible su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com