Large-scale domestic waste incineration grate furnace

A domestic waste incineration and grate furnace technology, applied in the direction of incinerators, grates, combustion methods, etc., can solve the problems of complex mechanical structure of mechanical grate incinerators, difficulty in replacing parts for equipment maintenance, long production and production cycles, etc. , to achieve the effect of stable equipment, high safety and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

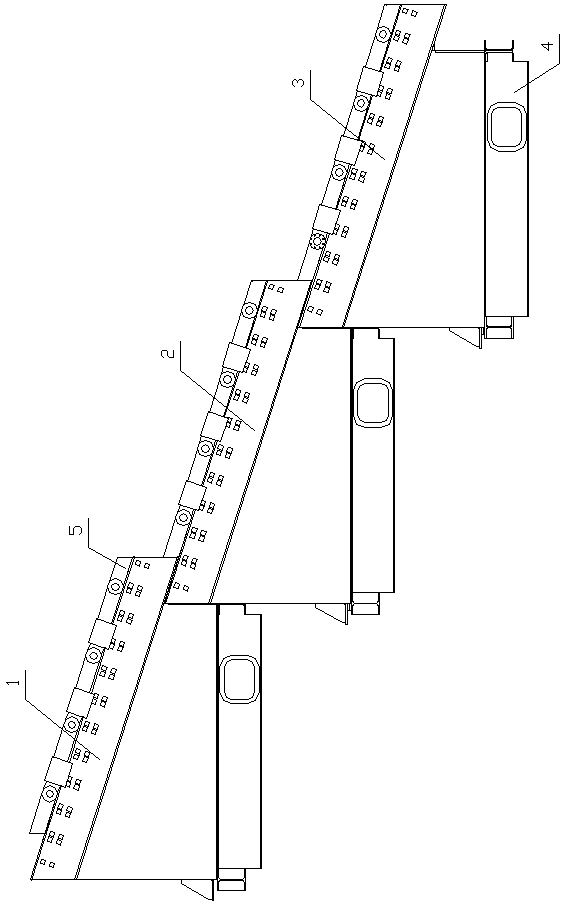

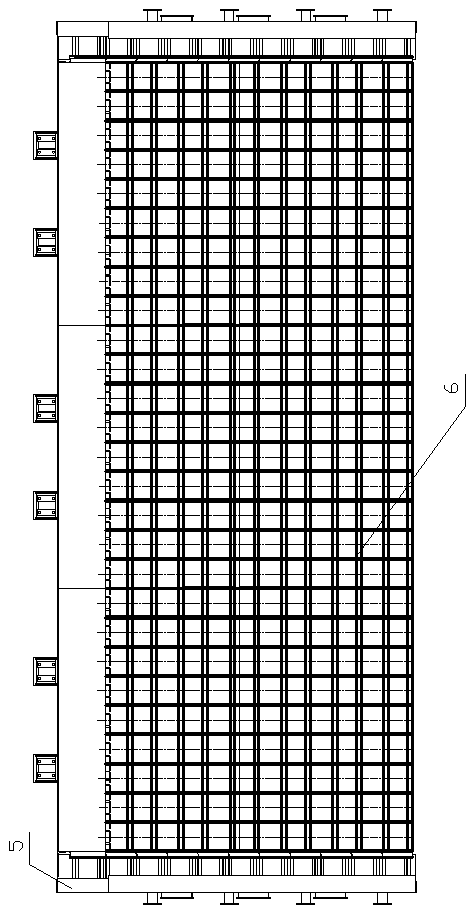

[0034] Such as figure 1 , 2 As shown, the present invention includes the drying section grate 1, the combustion section fire grate 2 and the burnout section fire grate 3 arranged in steps, and the drying section fire grate 1, the combustion section fire grate 2 and the burnout section fire grate 3 adopt the same The modular structure includes a grate support frame 4 respectively, side frames 5 are symmetrically arranged on both sides of the grate support frame 4, and a plurality of modular incinerators arranged in steps are arranged on the grate support frame 4 between the side frames 5. Grate unit6.

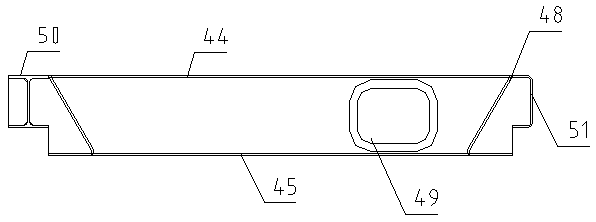

[0035] Such as image 3 , 4 As shown, the grate support frame 4 includes a square frame surrounded by an upper support steel plate 44, a lower support steel plate 45, and a front baffle 46 made of steel plates, and a rear baffle 47. The front baffle is provided with a maintenance manhole 49 , both sides between the upper supporting steel plate 44 and the lower supporting ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com