Electromagnetic de-enzyming machine with rotor

A greening machine and electromagnetic technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., to achieve the effect of improving life, reducing coaxiality requirements, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

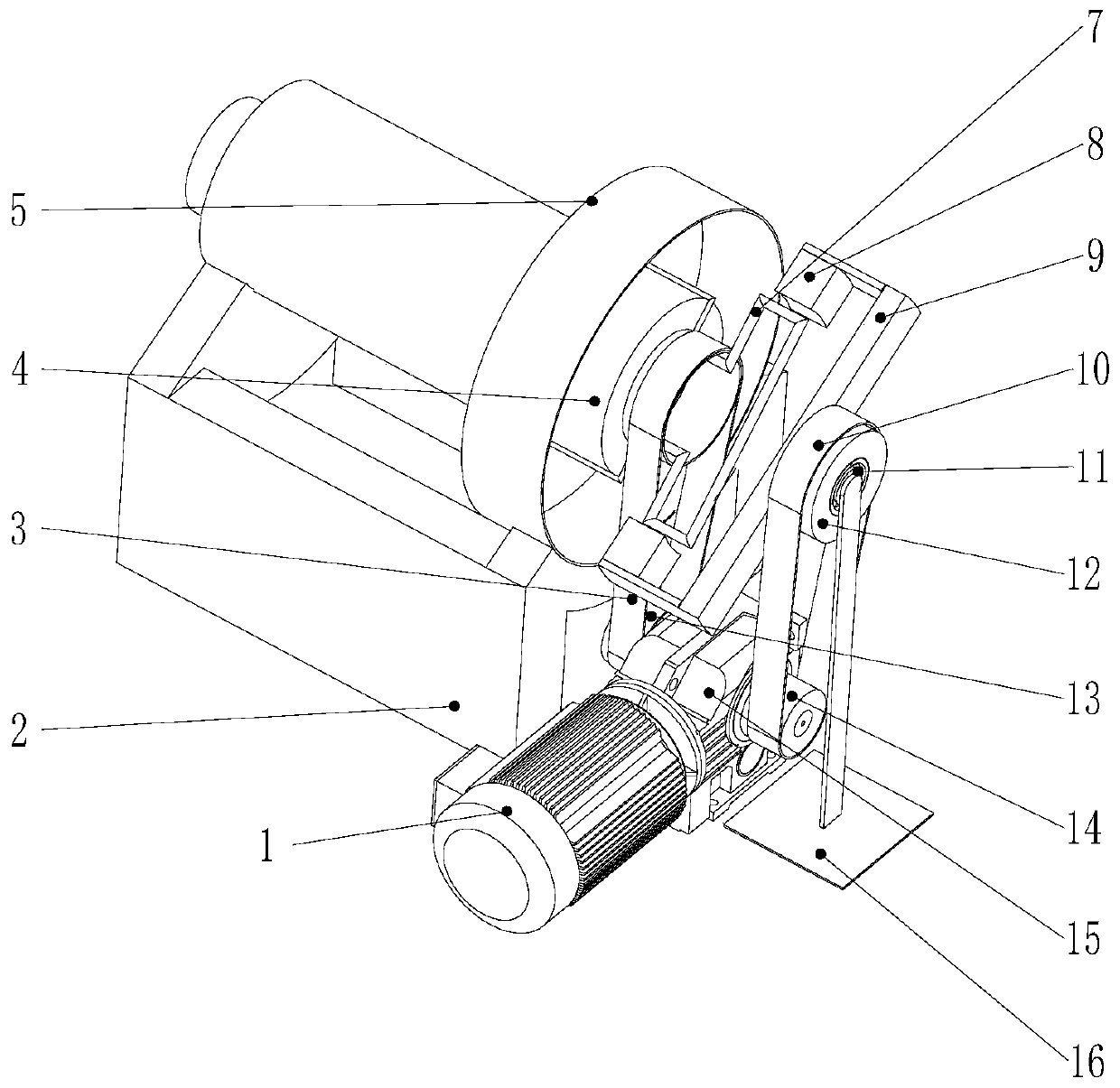

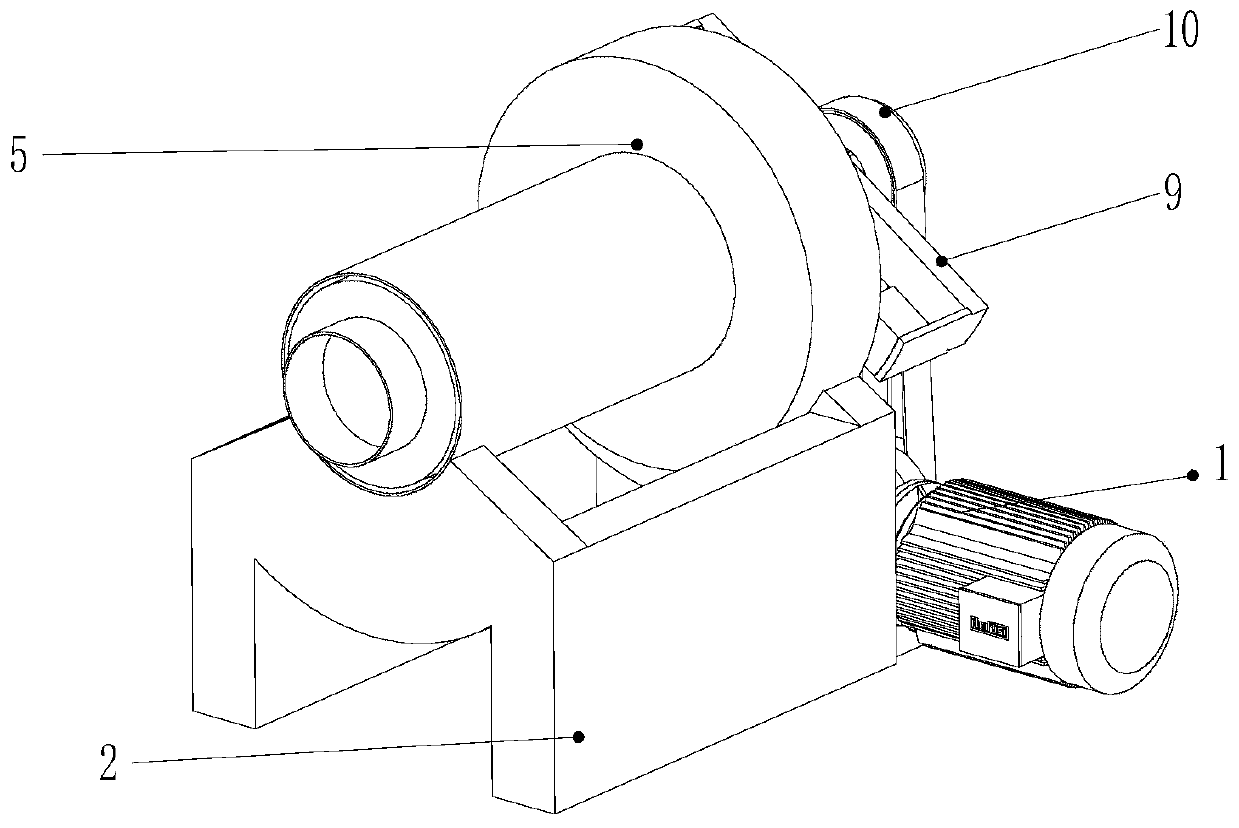

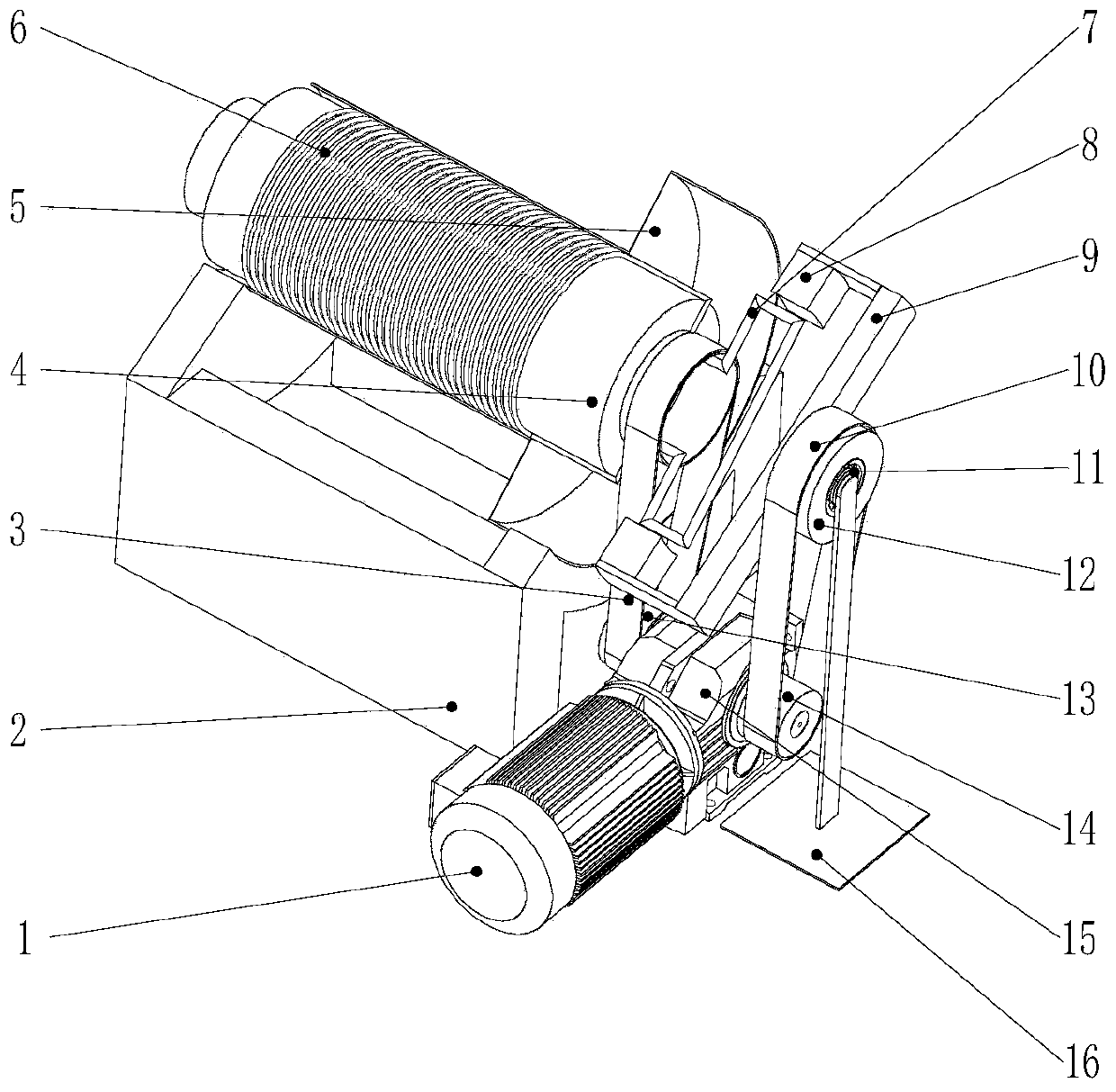

[0038] The present invention will be further described below in conjunction with accompanying drawing:

[0039]Such as Figure 1~4 As shown, an electromagnetic greening machine with a rotor includes a drive motor 1, a frame 2, a belt 3, a drum 4, a housing 5, a helical coil 6, a conductor 7, an energized helical tube 8, an energized helical tube fixture 9 and The driving pulley, the drive motor 1 and the frame 2 are fixed on the level ground, the housing 5 is horizontally installed on the frame 2, the drum 4 is set in the housing 5, and the two ends of the drum 4 pass through the bearing Supported on the inner wall of the housing 5, one end of the drum 4 is provided with a drive shaft, and the driving pulley is installed on the belt 3 wheel of the driving motor 1, and the driving shaft of the driving pulley and the drum 4 is connected by the belt 3, and the driving motor 1 moves Drive the belt 3 to rotate through the driving pulley, and then drive the drum 4 to rotate; the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com