Lifting buoyant platform for above-water maintenance of warship

A technology for buoyancy platforms and ships, which is applied in lifting frames, ships, lifting devices, etc., can solve the problems of unusable large maintenance tools and inconvenient maintenance, and achieve the effects of convenient maintenance, load reduction and increased buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

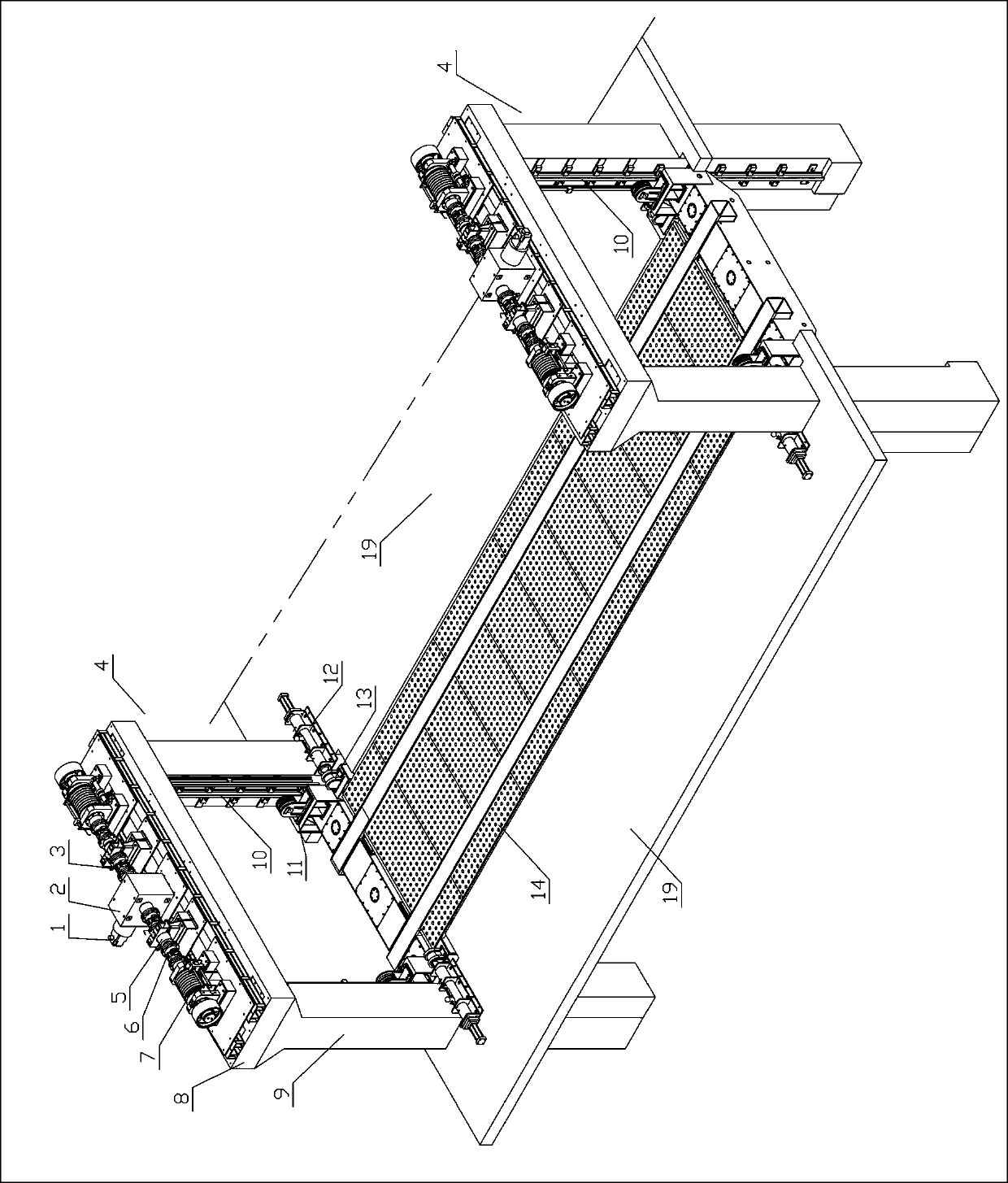

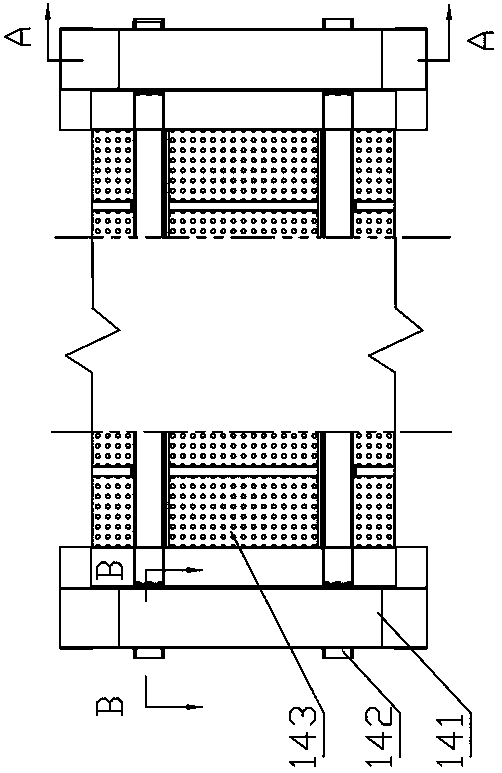

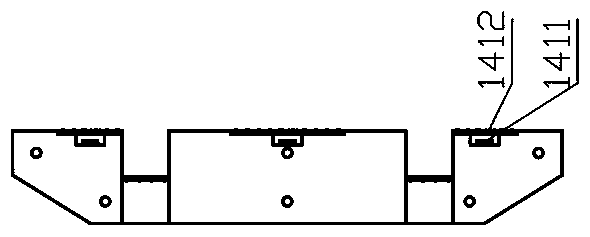

[0026] see Figure 1-13 , the present embodiment includes a fixed overhaul workshop 19, which is built on the water channel of the water surface overhaul workshop 19, and two gantry frames 4 are arranged at the front and rear of the water area channel, and a lifting buoyancy platform 14 is installed between the two gantry frames 4 , the top of each gantry 4 is equipped with a hoisting device 18, and the hoisting device 18 controls the lifting and lowering buoyancy platform 14 to rise and fall, and the two ends of the lifting buoyancy platform 14 are provided with buoyant tanks 141, and two buoyant tanks 141 are equipped with Airtight hollow beam 142, the hollow beam 142 is equipped with a porous flat plate 143, the buoyancy tank 141 is a trapezoidal airtight hollow box body, the box body is provided with an installation port at the hollow beam 142 installation position, the four corners of the lifting buoyancy platform 14 There is a pulley block 11 connected with the hoisting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com