Blowing system of chain boiler with sectorial blow homogenating plate

A chain boiler and air distribution system technology, which is applied in the direction of furnace grate, mobile furnace grate, combustion air/fuel supply, etc., to achieve the effects of reducing airflow deviation, fully burning coal, and increasing combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

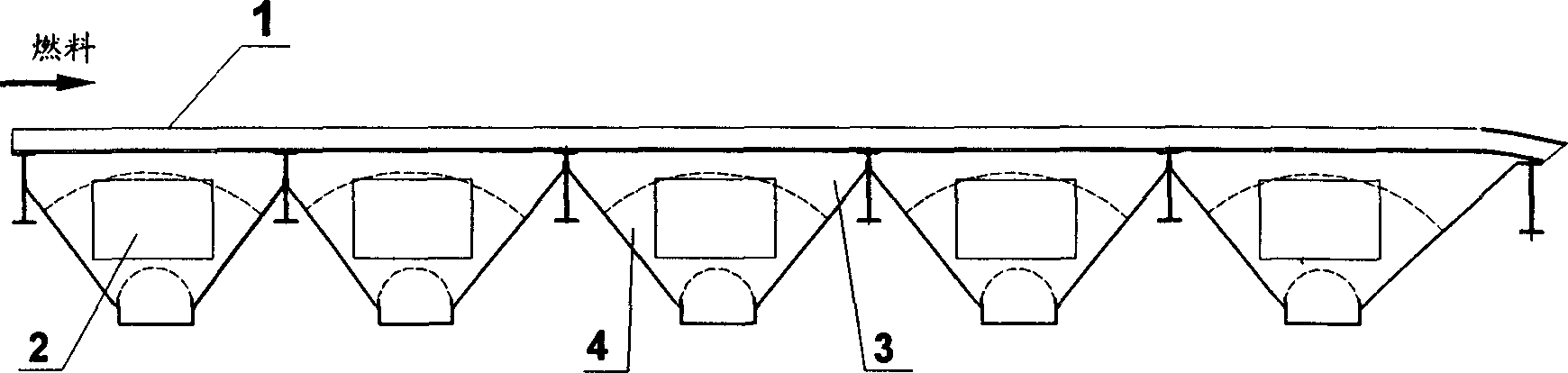

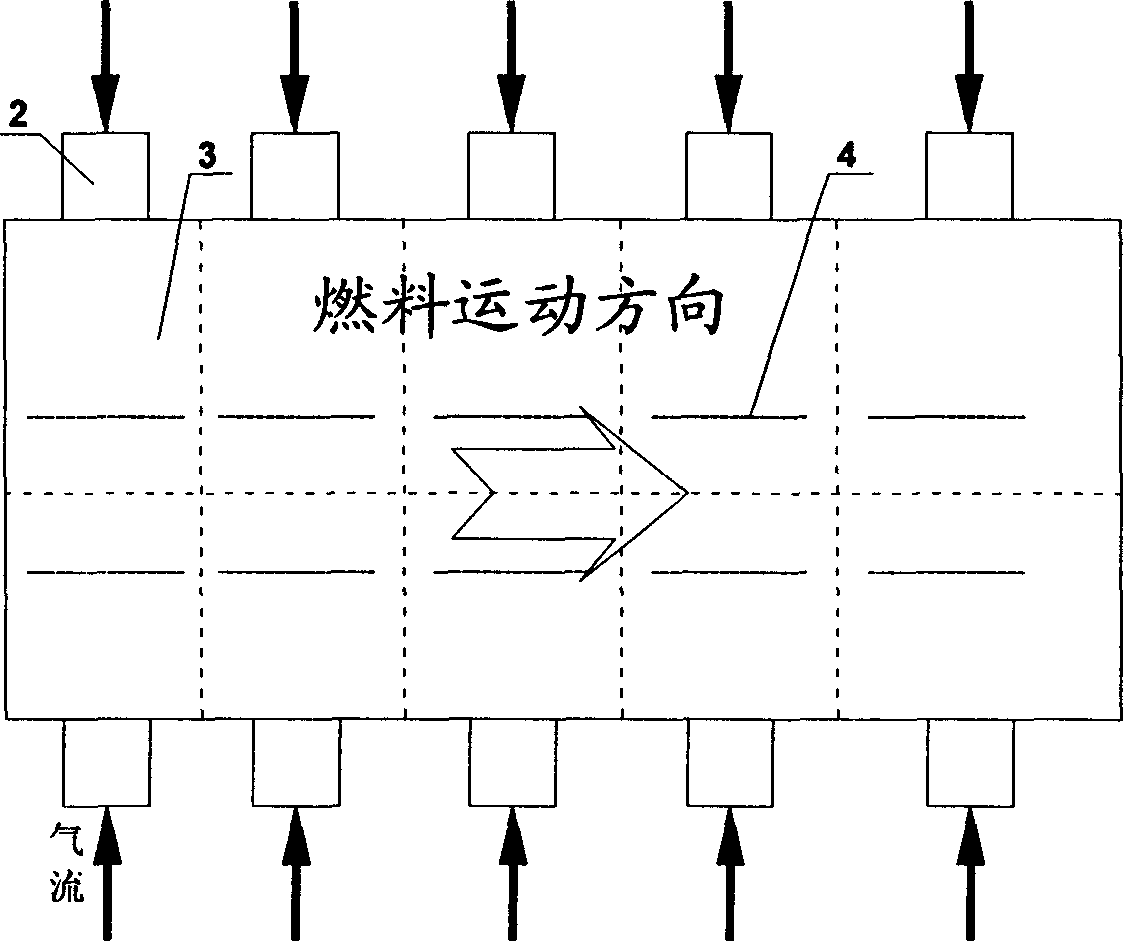

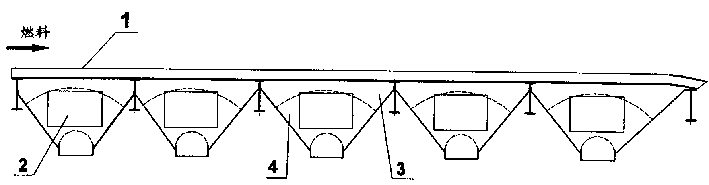

[0015] The chain boiler air distribution system structure of the present invention is as follows: figure 1 , figure 2 shown. Considering factors such as falling ash, the cross section of the air chamber 3 is a trapezoidal shape with a large upper part and a smaller lower part, and a fan-shaped air equalizing plate 4 is installed in the air chamber 3. The air equalizing plate is inserted into the air chamber, and its plane is perpendicular to the direction of air flow. It is welded to the two walls of the air chamber and does not touch the ash bucket at the bottom of the air chamber, so it will not affect the ash fall.

[0016] The fan-shaped air distribution plate can be a thin steel plate with a thickness of 5mm.

[0017] The air used for combustion enters the air chamber 3 from the air inlet pipe 2, passes through the fire grate 1 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com