Biomass molding fuel combustion boiler

A technology for forming fuel and biomass, which is applied in the combustion of solid fuel, combustion method, combustion equipment, etc., can solve the problems of lowering the melting point of biomass ash, can not be used normally, straw ash is easy to slagging, etc. The effect of raising temperature and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

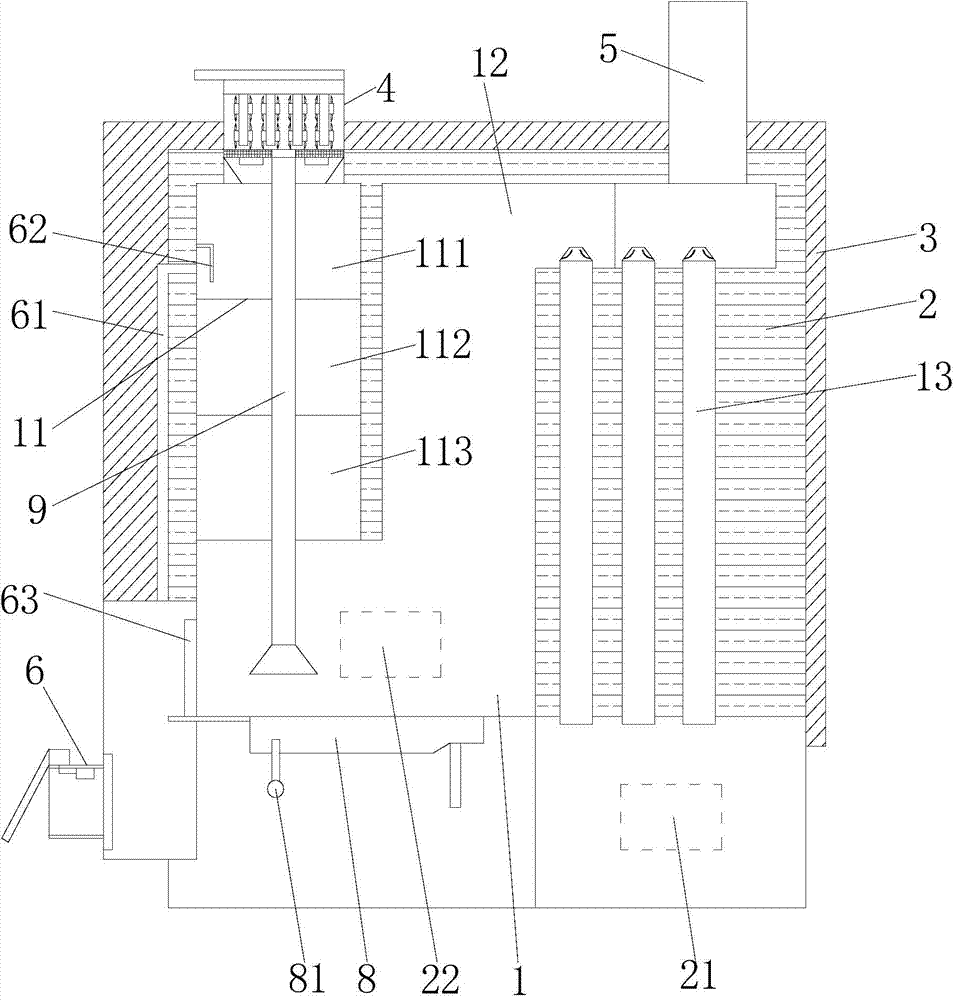

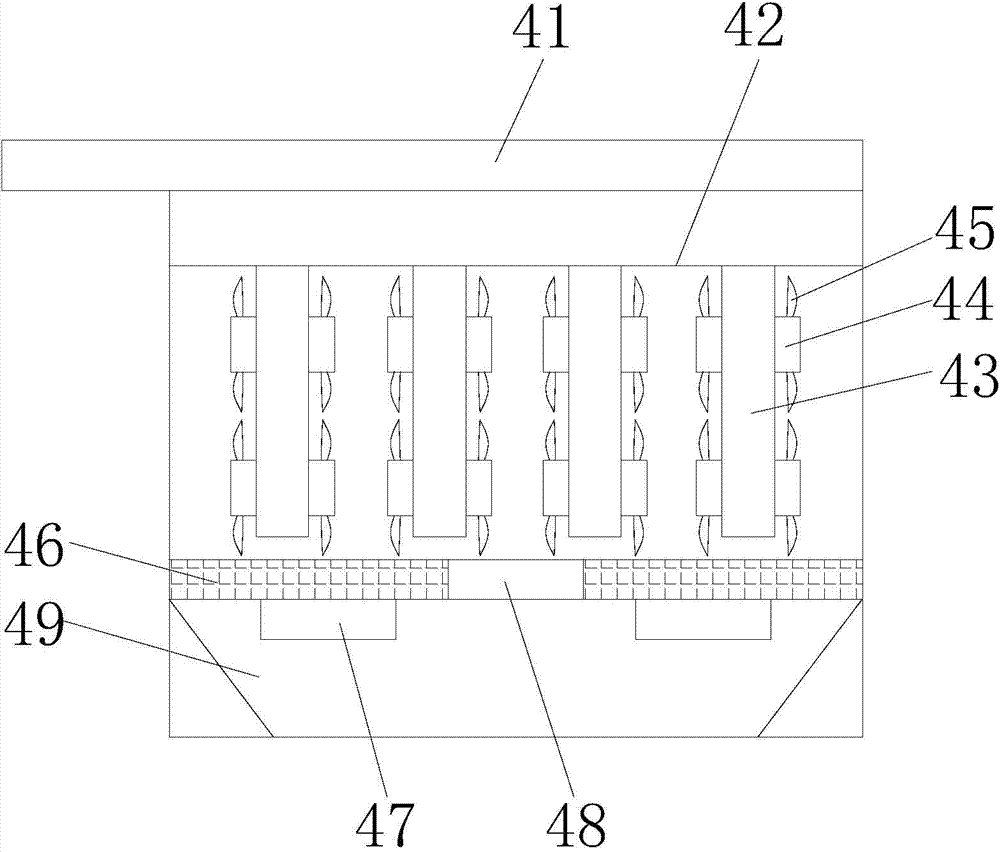

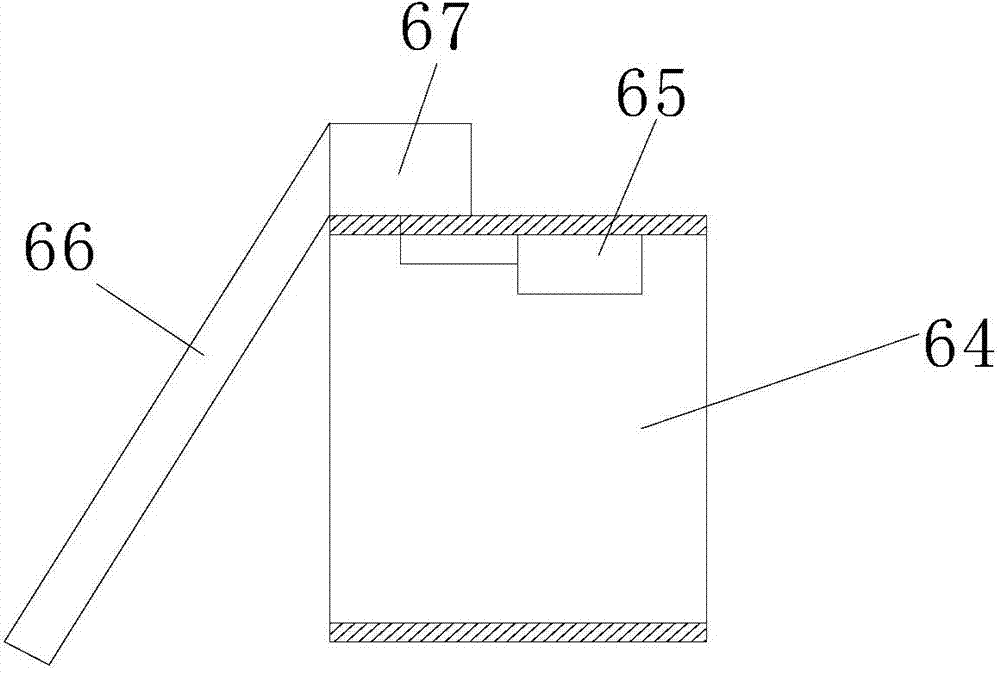

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a biomass molding fuel combustion boiler of the present invention, comprising a furnace 1, a water-cooled wall layer 2 and an insulation layer 3, the water-cooled wall layer 2 is coated on the outside of the furnace 1, and the insulation layer 3 is coated on the outside of the water-cooled wall layer 2, A charging port 4 and a chimney 5 are installed on the top of the furnace 1, a charging door 41 is installed on the charging port 4, a crushing device 42 is installed in the charging port 4, and several rotating shafts 43 are arranged in the crushing device 42. A rotating head 44 is installed on the rotating shaft 43, a crushing blade 45 is installed on the rotating head 44, a mesh screen 46 is installed at the bottom of the crushing device 42, a vibration motor 47 is installed at the bottom of the mesh screen 46, and a through hole is arranged on the mesh screen 46 48. The furnace 1 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com