Coal burning hot air furnace with horizontal-reciprocating grate

A horizontally reciprocating, hot-blast stove technology, applied in the direction of mobile grates, grates, combustion chambers, etc., can solve the problems of impossible complete combustion of coal, uneconomical, low thermal efficiency of hot-blast stoves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

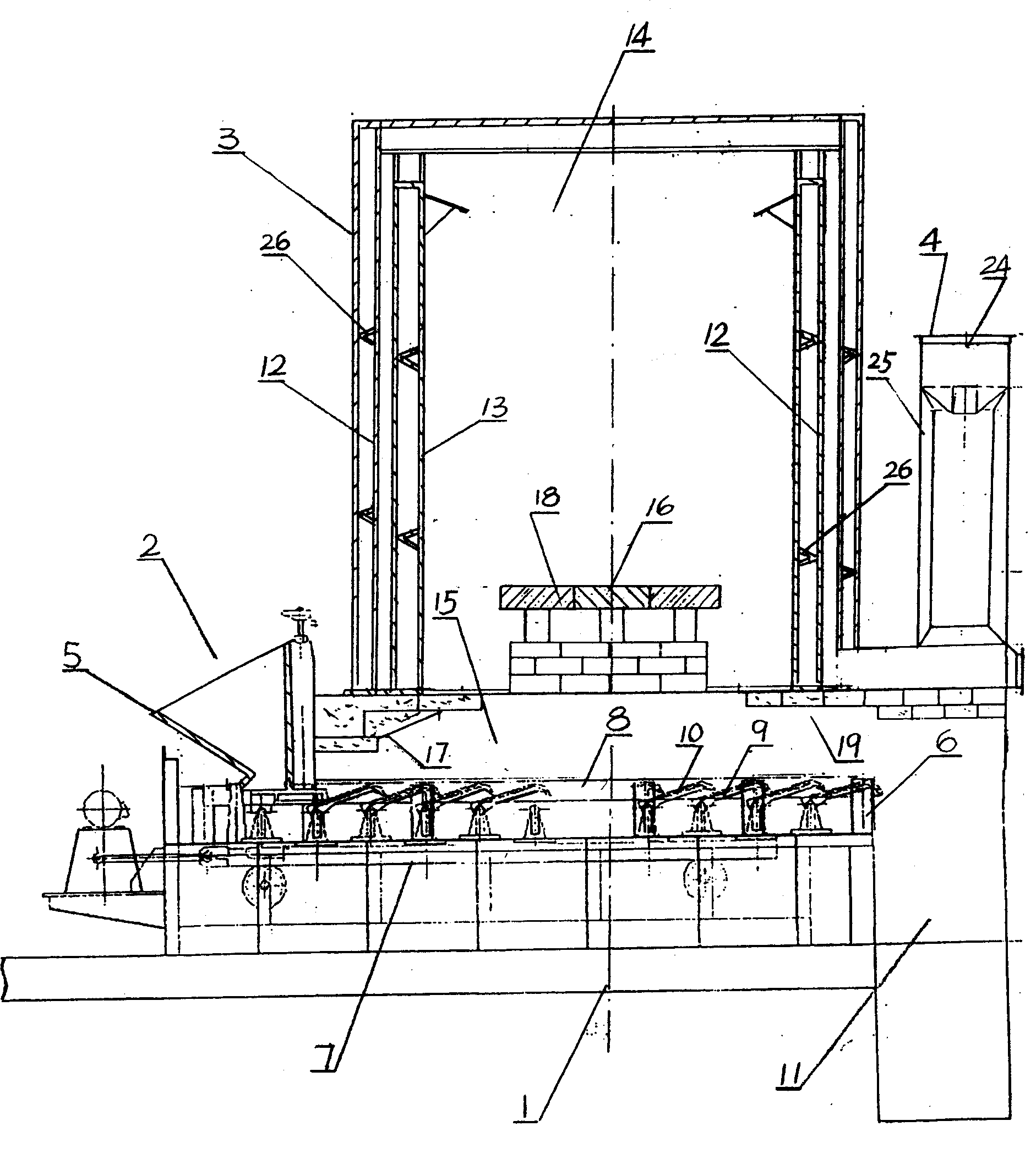

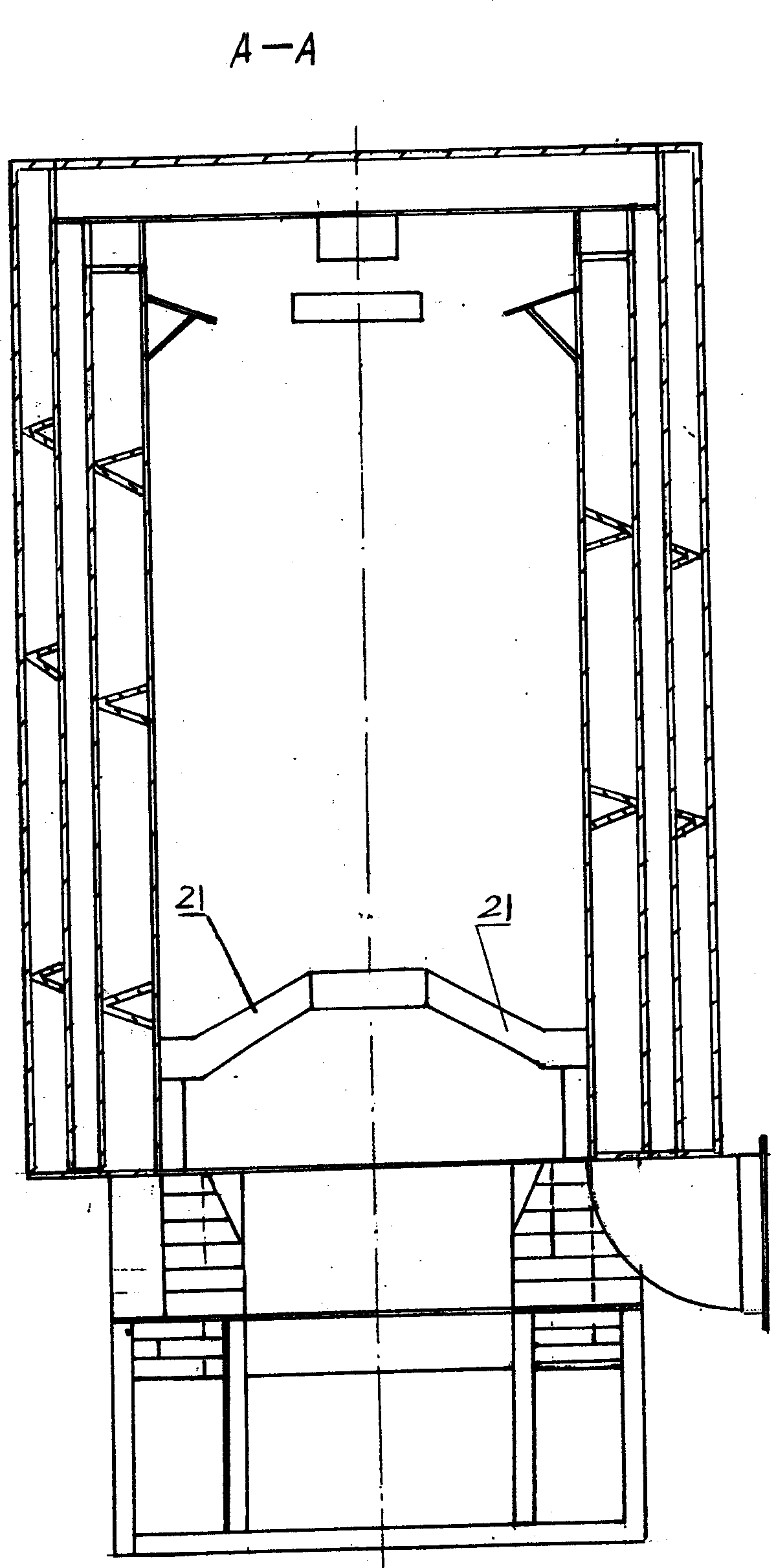

[0012] Control attached figure 1 , the hot blast stove includes an insulated elongated furnace chamber 1, the furnace chamber is made of refractory materials, the front end of the furnace chamber is provided with a feed port 2, and the upper end of the furnace chamber is provided with a heat exchange device 3 composed of a cylinder , a ring-shaped or oval-shaped vertical sleeve heat exchanger, connected to a tube-and-tube pre-heat exchanger 4 at its rear end.

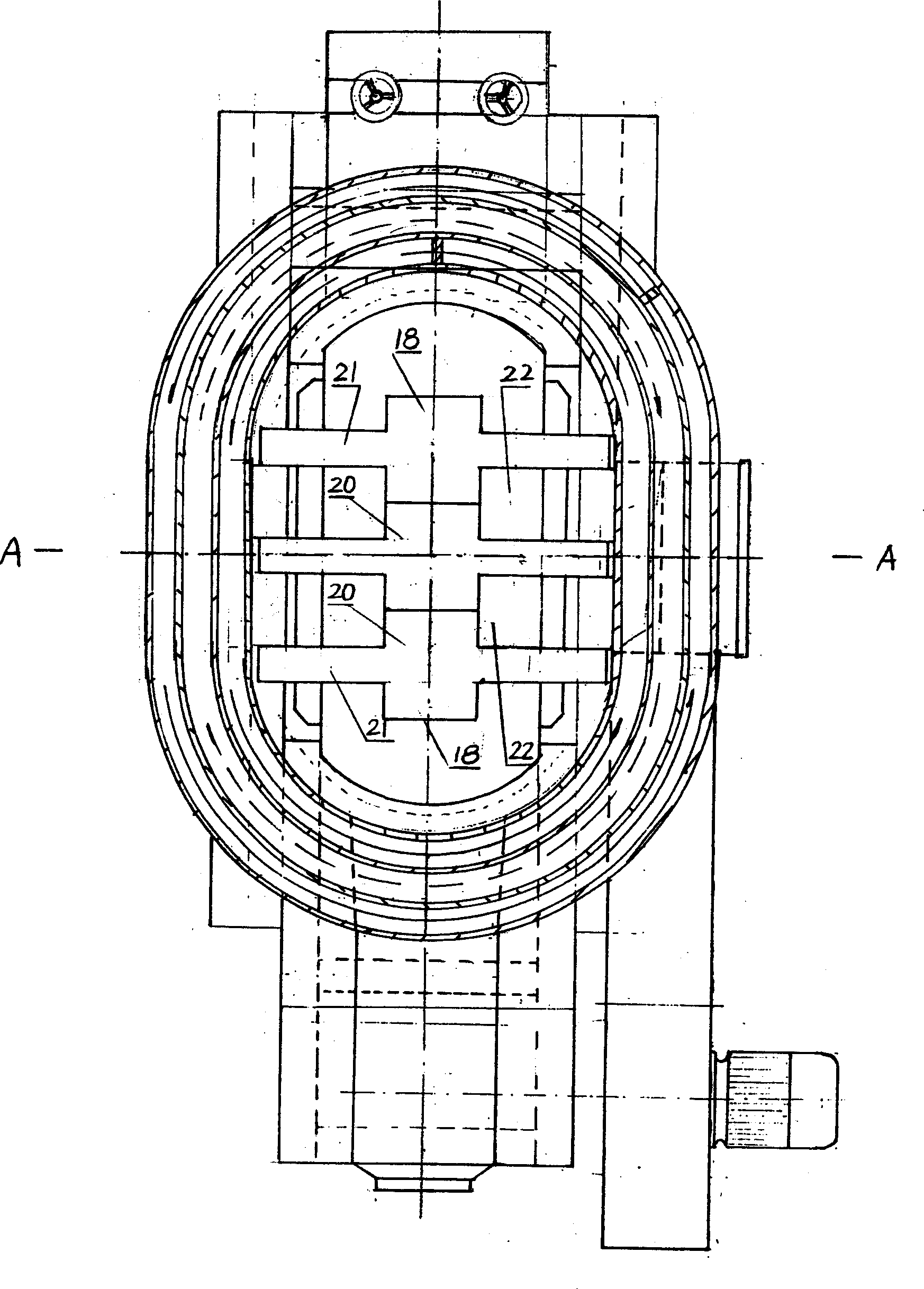

[0013] The front end of the furnace chamber 1 is provided with a coal scuttle 5 forming the feed inlet 2, and a set of coal burner is connected with the coal scuttle 5. The coal burner of this embodiment is a horizontally reciprocating grate machine 6, which The main structure includes a movable beam 7, a fixed beam 8, a movable grate piece 9, and a fixed grate piece 10. The front ends of the two kinds of grate pieces are curved, and the rear end has a half hole to match the shaft. The two kinds of grate pieces are over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com