Household garbage incinerator

A technology for domestic waste incineration and incinerator, which is applied to incinerators, grate, combustion methods, etc., can solve problems such as insufficient combustion, and achieve the effects of sufficient combustion, uniform temperature distribution, and increased uniformity of temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

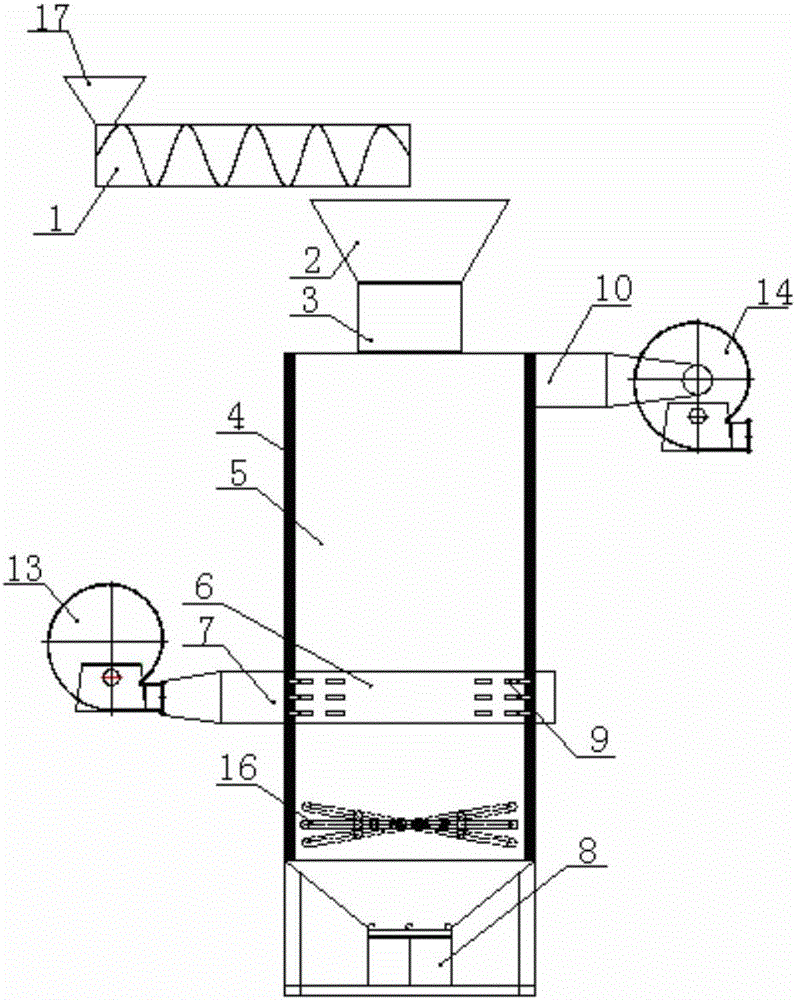

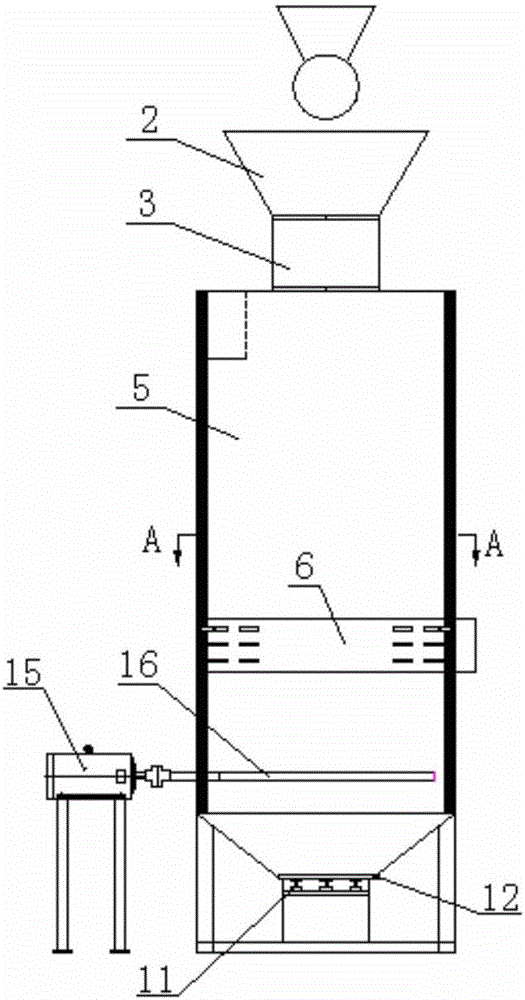

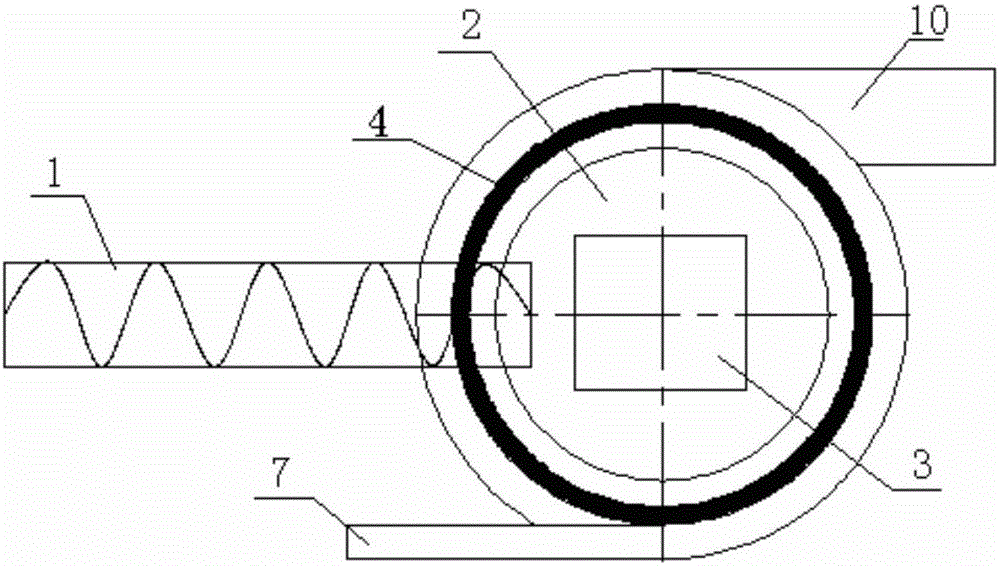

[0046] see figure 1 with figure 2 , the garbage incinerator in the illustration is a preferred embodiment of the present invention, specifically including a screw conveyor 1, a feed hopper 2, a furnace door 3, a refractory insulation layer 4, a furnace chamber 5, an annular air inlet duct 6, an air inlet 7. Slagging and dust removal door 8, injection pipe 9, exhaust port 10, furnace bridge 11, fixed fire grate 12, blower 13, induced draft fan 14, driving motor 15, movable fire grate 16 and garbage hopper 17.

[0047] Specifically, a furnace door 3 is arranged on the top of the furnace chamber 5 of the incinerator, and feeds are fed into the furnace chamber through a feeding system. The feeding system adopts a screw conveyor 1. One end of the screw conveyor 1 is connected to the garbage hopper 17, and the other end is connected to the feeding hopper 2 on the top of the furnace chamber. The furnace door 3 is arranged at the bottom of the feeding hopper 2. Reconnection, the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com