Isobaric air supplying and suspension active propelling unit for novel large reciprocating grate

A technology of reciprocating grate and propulsion device, which is applied in the direction of grate, mobile grate, combustion air/fuel supply, etc., and can solve the problem of large-scale grate boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

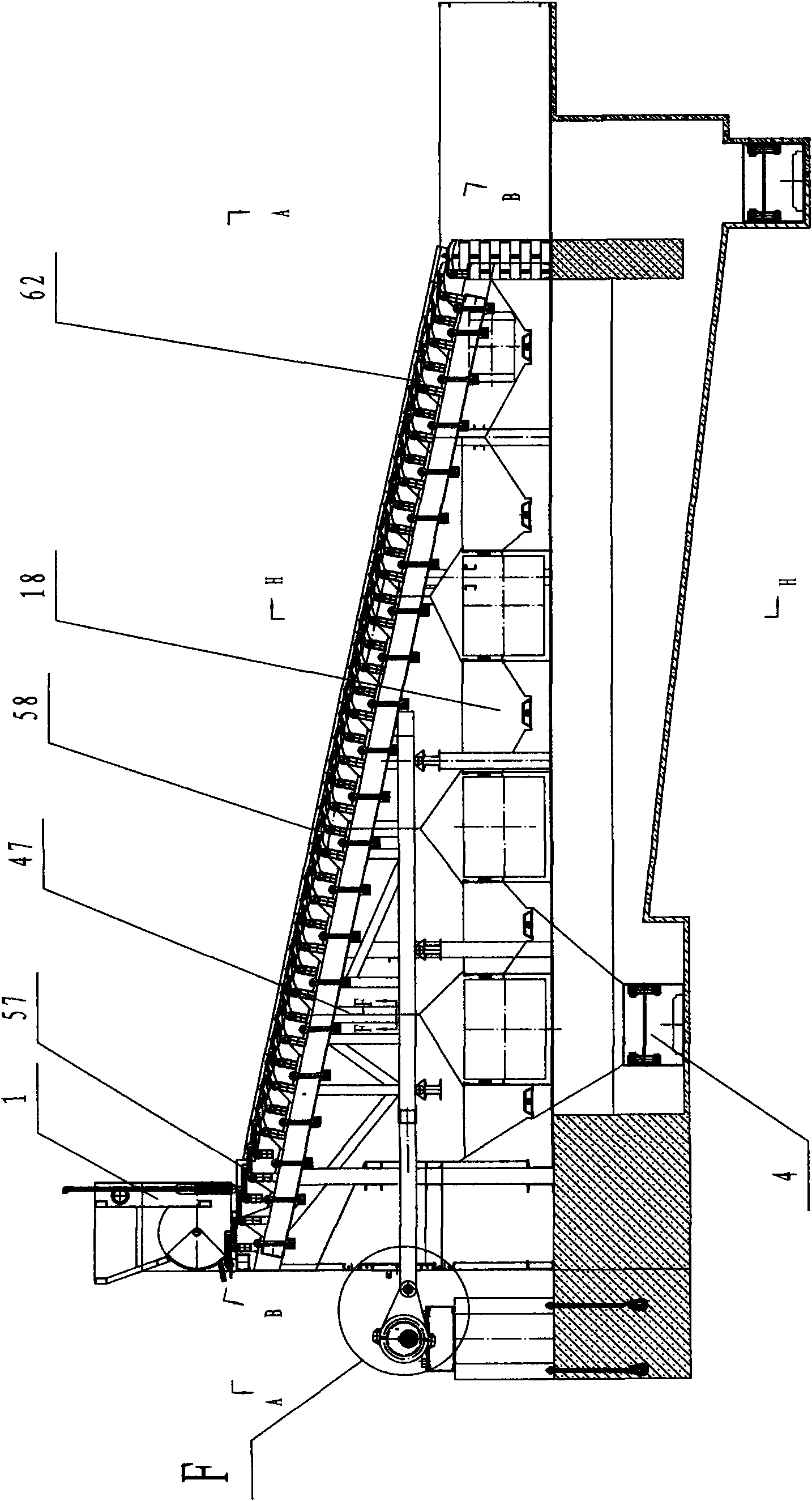

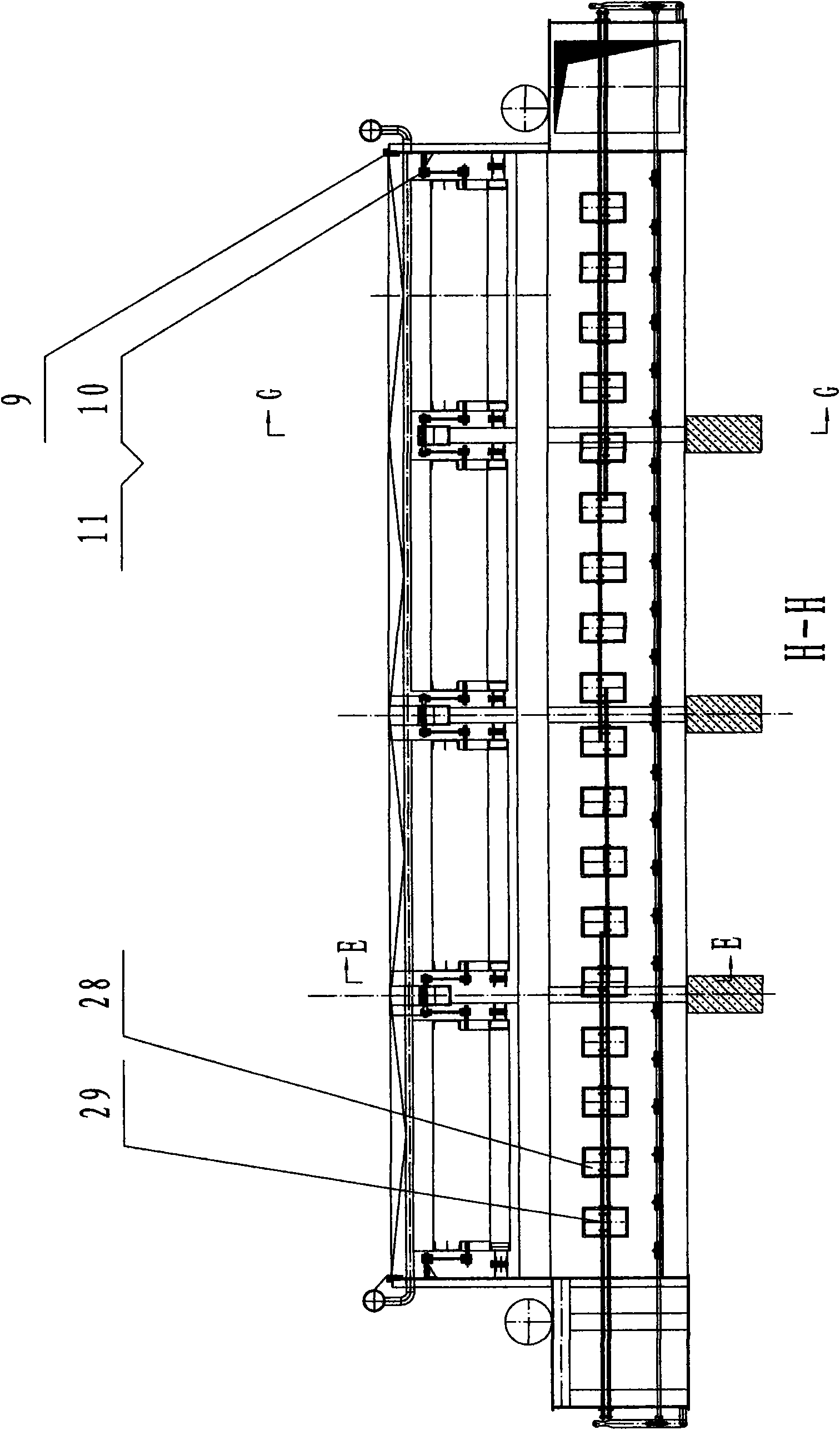

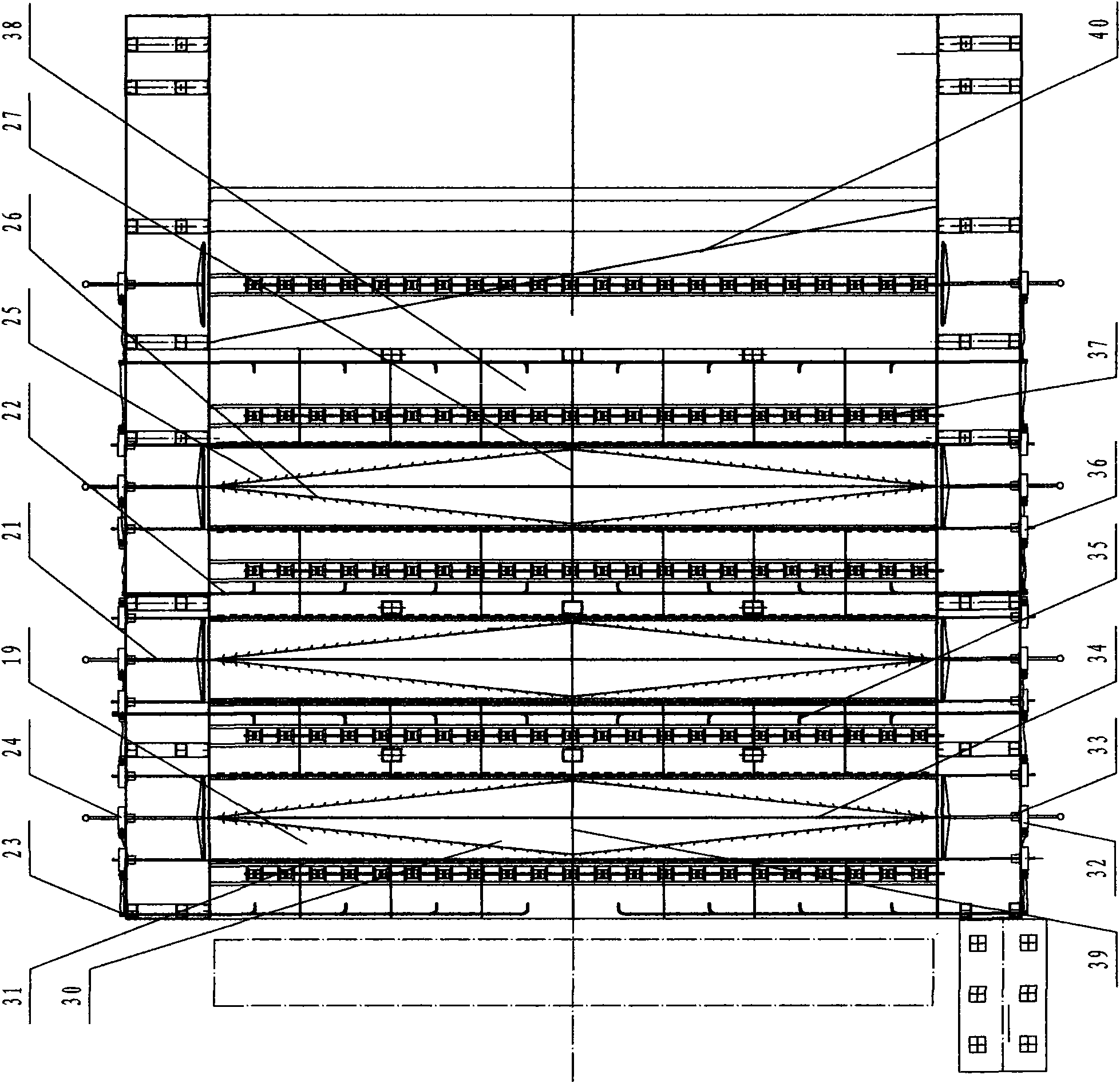

[0058] The present invention is a novel large-scale reciprocating grate isobaric air supply and suspension movable propulsion device, which involves the utilization of the aerodynamic principle of purifying central air-conditioning and the combustion design specifications of reciprocating grate boilers to implement equal-pressure air supply in large reciprocating chain grate boilers With the suspension movable propulsion device, the purpose is to implement and improve the reciprocating grate boiler. The historical problems of wind pressure and air supply that restrict its large-scale development, the bearing load of reciprocating mechanical movement, the problem of thermal stress bearing deformation, asynchronous reciprocating movement of large machinery, and frequent mechanical failures Unstable boiler operation. The implementation of the mechanical reciprocating motion of the present invention is achieved in this way: the main drive shaft (61) driven by the drive motor and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com