Ultra-high vacuum rotary feed-in device

An ultra-high vacuum, worm technology, applied in the direction of electromechanical devices, transmission parts, casings/covers/supports, etc., can solve the problems of small effective diameter, large structure, large outer diameter of the device, etc., to avoid direct bearing The pressure, the device structure is simple, and the effect of improving the control accuracy

Pending Publication Date: 2019-08-27

费勉仪器科技(南京)有限公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the prior art, the rotary feed-in device mostly uses angular contact bearings, deep groove ball bearings or cross roller bearings with fixed threaded holes as supports; if angular contact bearings are used as supports, the device usually has a large outer diameter and an effective diameter Small, the device shakes a lot during use, has poor load-bearing capacity, is prone to powder contamination, and the sealing ring is squeezed, wears a lot, and has a short life; if a crossed roller bearing with a fixed threaded hole is used as a support, the overall structure of the device is too Huge, bulky, small effective diameter, poor device compatibility, and severely limited use conditions; if deep groove ball bearings are used as the supporting structure, the device will have weak load-bearing capacity, large shaking, serious wear of the sealing ring, and short service life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

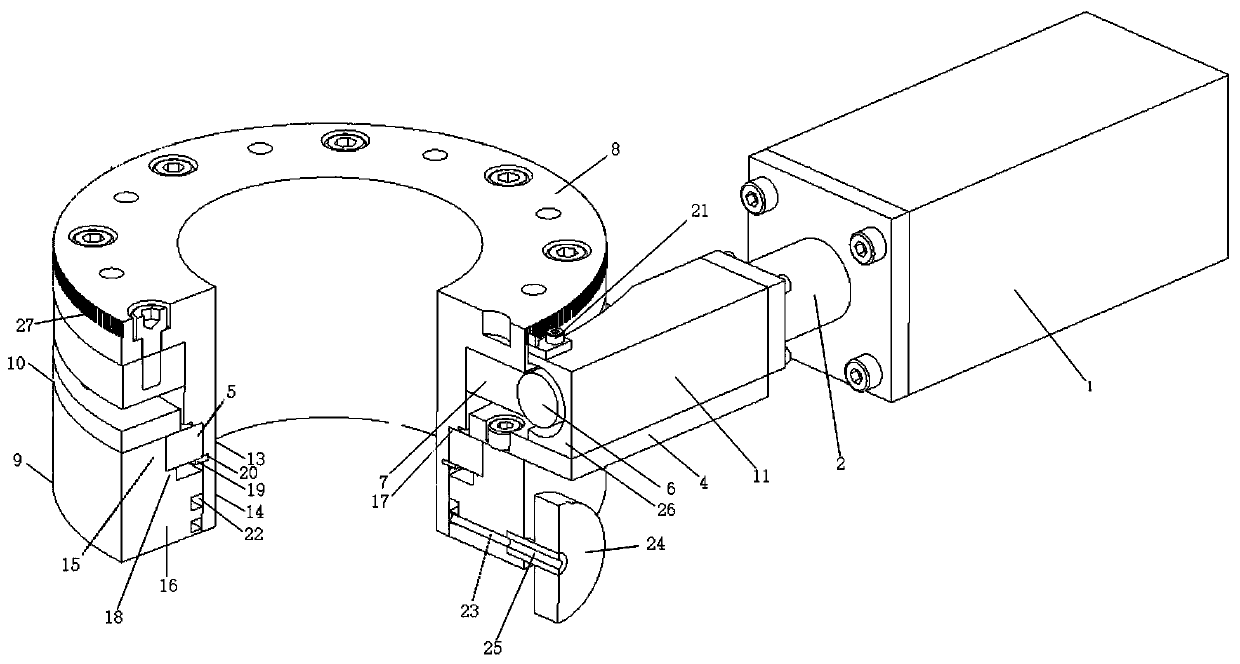

[0041] In a preferred embodiment, as Image 6 As shown, the difference from Embodiment 1 is that the worm support 11 and the bearing outer ring cover plate 10 are integrally manufactured. The worm support 11 and the bearing outer ring cover plate 10 can be cast by means of integrated casting, which can effectively improve the load-bearing capacity of the device.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

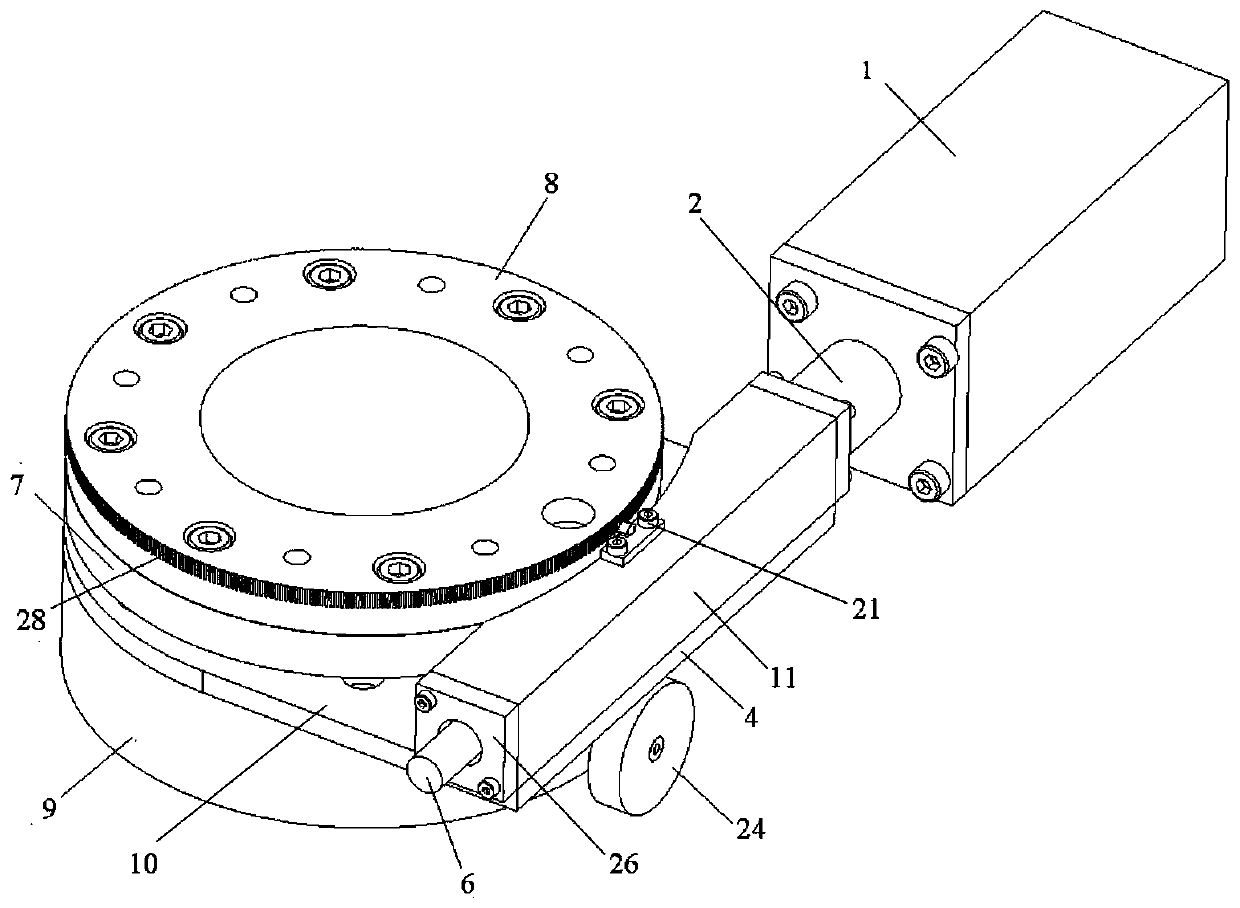

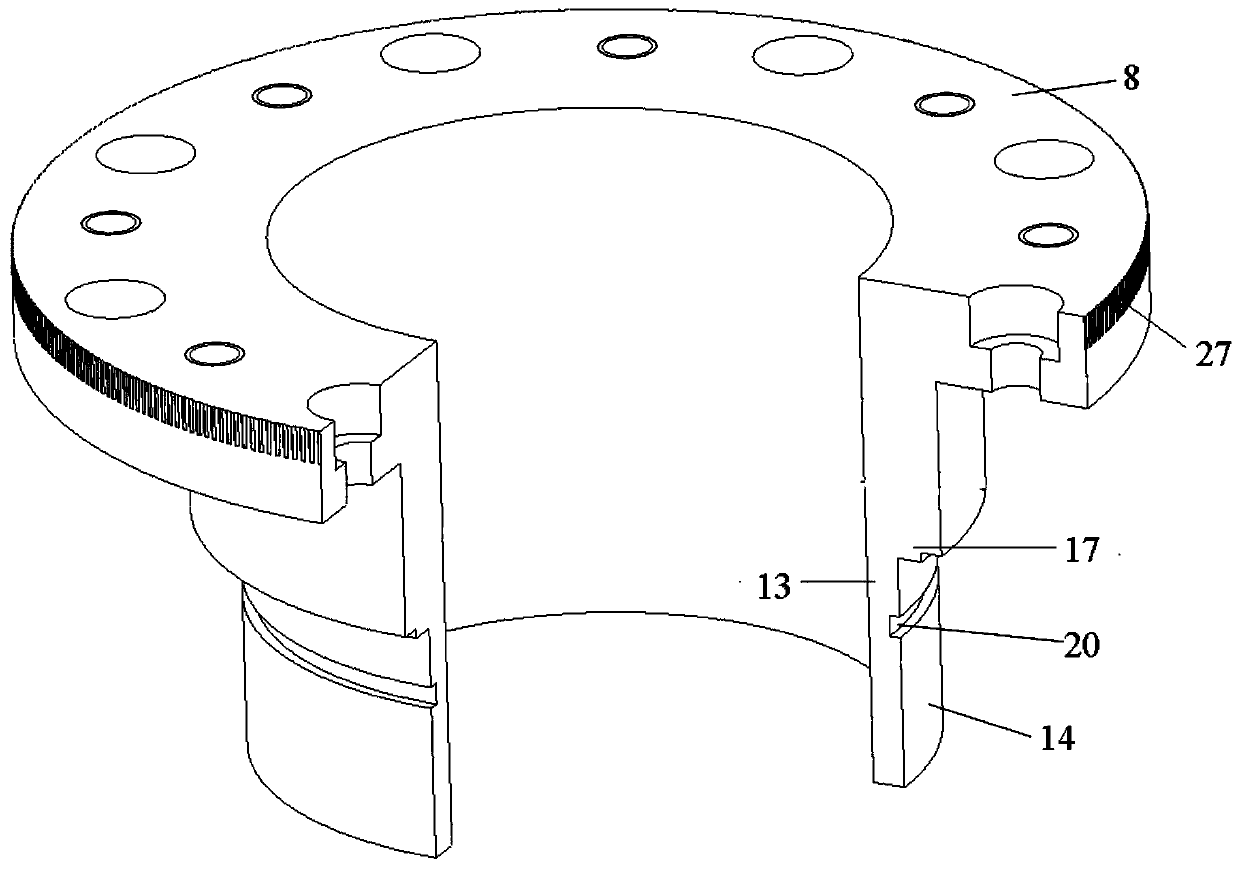

The invention provides a ultra-high vacuum rotary feed-in device, which is used for solving the technical problems that in the prior art, a rotary feed-in device is small in effective drift diameter,poor in bearing capacity and sealing performance, and seaming rings of the rotary feed-in device are easy to damage. The ultra-high vacuum rotary feed-in device comprises a motor, a motor support, a coupling, a fixing frame, a cross roller bearing, a worm, a worm wheel, an upper flange and a lower flange, wherein the fixing frame comprises a bearing outer ring cover plate, a worm support and a worm fixing part, the upper flange comprises an inner ring fixing end and an extension end, and the lower flange comprises an outer ring fixing end and a sealing end. According to the technical scheme, the worm and the worm wheel are used as a main transmission mechanism, so that the device is simple in structure; sealing rings are arranged on the inner side of the lower flange, thus being capable ofavoiding directly bearing pressure so as to prolong the service life of the sealing rings; with the cross roller bearing arranged, the shaking generated in the working process of the device is reduced, and the control precision of the device is improved; and the plurality of sealing rings and a differential extraction flange are arranged, and accordingly the device is applicable to an ultra-highvacuum cavity.

Description

technical field [0001] The invention relates to the field of ultra-high vacuum reaction devices, in particular to an ultra-high vacuum rotary feeding device. Background technique [0002] In the prior art, the rotary feed-in device mostly uses angular contact bearings, deep groove ball bearings or cross roller bearings with fixed threaded holes as supports; if angular contact bearings are used as supports, the device usually has a large outer diameter and an effective diameter Small, the device shakes a lot during use, has poor load-bearing capacity, is prone to powder contamination, and the sealing ring is squeezed, wears a lot, and has a short life; if a crossed roller bearing with a fixed threaded hole is used as a support, the overall structure of the device is too Huge, bulky, small effective diameter, poor device compatibility, and severely restricted use conditions; if deep groove ball bearings are used as the supporting structure, the device will have weak load-beari...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16H57/021F16H57/023F16H57/025F16H57/029F16H57/039H02K7/116H02K5/173G01B5/24

CPCF16H57/021F16H57/023F16H57/025F16H57/029F16H57/039H02K7/1166H02K5/173G01B5/24F16H2057/0213F16H2057/02034

Inventor 谢斌平郭云飞

Owner 费勉仪器科技(南京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com