Novel reciprocating furnace grate

A reciprocating grate and grate technology, which is applied in the direction of grates, mobile grates, lighting and heating equipment, etc., can solve the problems of affecting the combustion effect of coal blocks and sticking coal blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

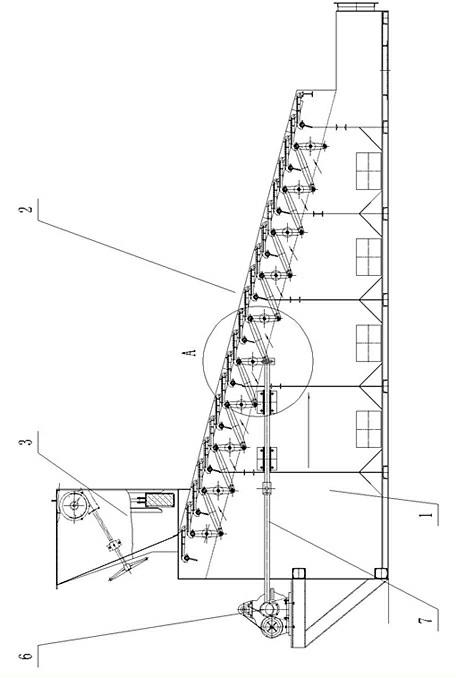

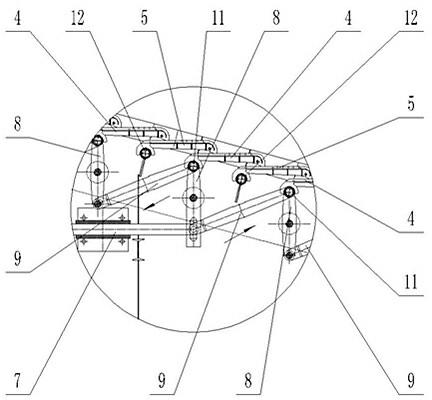

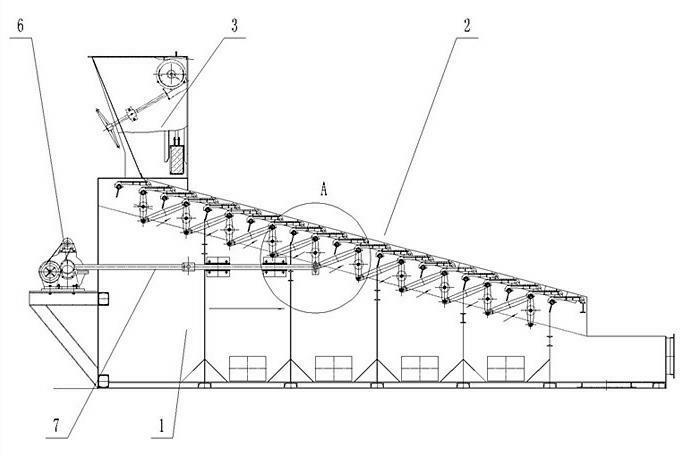

[0009] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 Shown: a new type of reciprocating fire grate, including a fire grate shell 1, a plurality of fire grate pieces 2 are arranged on the upper end of the fire grate shell 1. A coal hopper 3 is arranged above the highest grate piece 2. The fire grate piece 2 is divided into two types: a movable piece 4 and a fixed piece 5, and the two are arranged at intervals. On the movable beam 11, the fixed piece 5 is hinged on the fixed beam 12 fixedly arranged inside the grate shell 1; a drive device 6 is arranged in the grate shell 1, and the drive device 6 is generally a reducer, and its The output end is a driving rod 7 that can move laterally. The other end of the other end is also hinged with the movable beam 11, and at the same time, another oblique connecting rod 9 is also hinged at this hinge point, and the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com