Method for mechanical stoking in firing installations and firing installation

a technology of mechanical stoking and firing plant, which is applied in the direction of combustion process, lump/pulverulent fuel feeder/distribution, grates, etc., can solve the problems of not being able to comply with provisions and no longer being able to burn completely before being discharged, so as to reduce the residual carbon content of ash, reduce the rotational speed of the thrower wheel, and increase the length of the trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

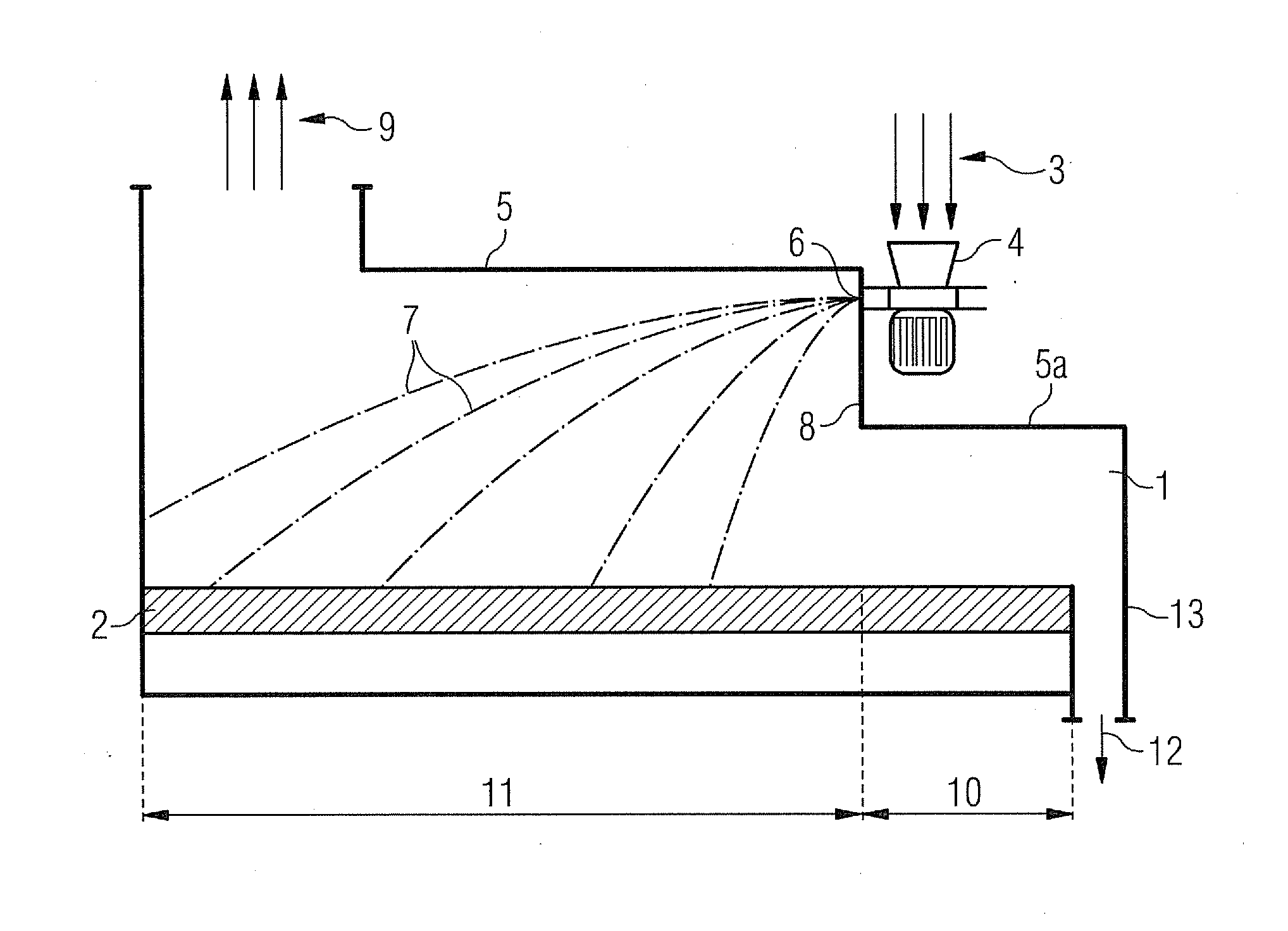

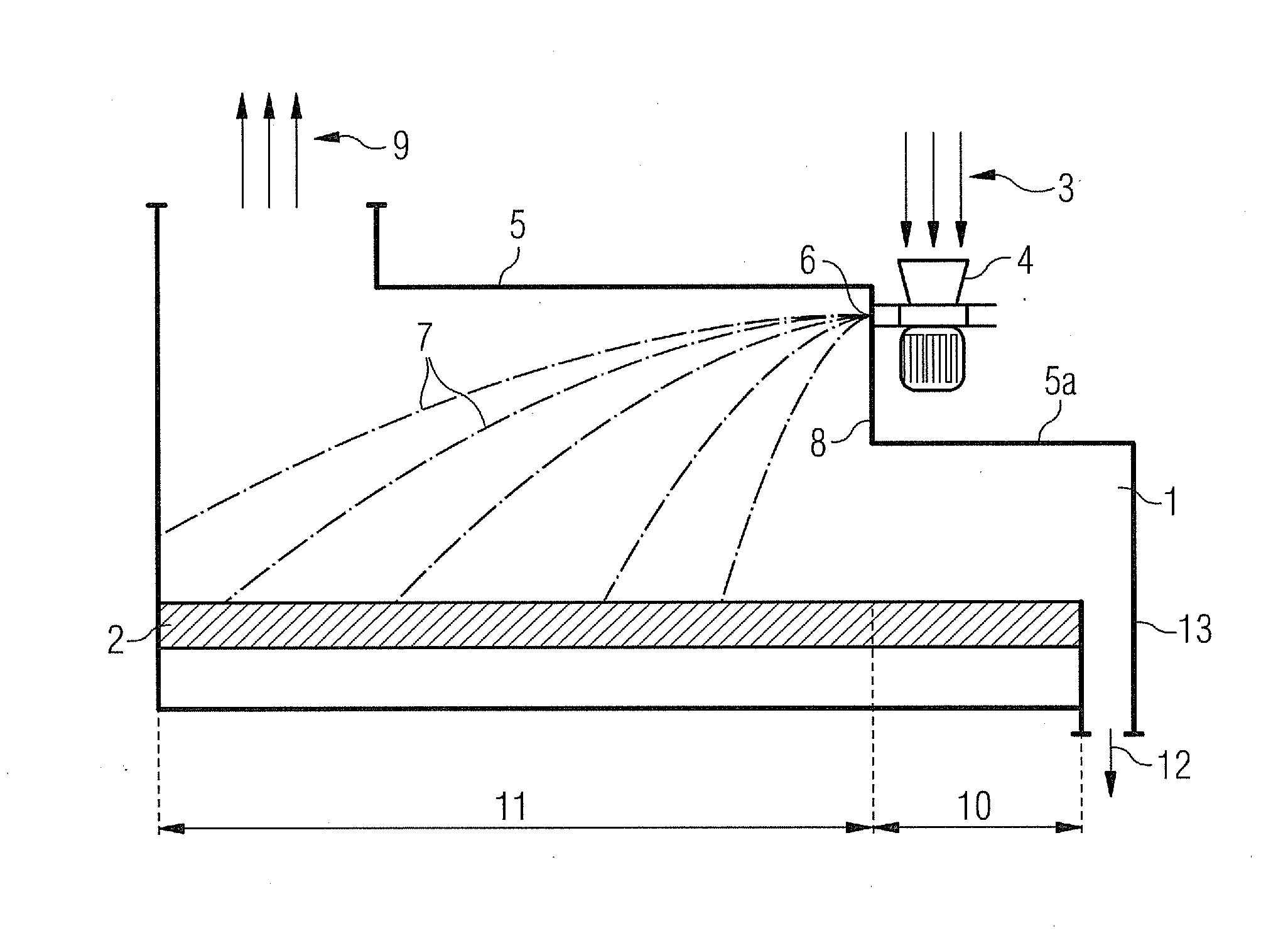

[0022]The figure schematically shows the combustion chamber 1 of a firing plant in which a grate 2 which conveys from left to right is disposed horizontally. Said forward-acting reciprocating grate consists of individual elements having bars oriented in the direction of conveyance (in this example the bars have a length of 500 mm), with only every second element being moved back and forth. The fuel 3 is supplied from above to a mechanical spreader stoker 4 and conveyed by means of the latter into the combustion chamber 1.

[0023]The mechanical spreader stoker 4 has a horizontally disposed thrower wheel, i.e. the axis of rotation of the thrower wheel is vertical. The fuel 3 is introduced into the mechanical spreader stoker 4 from above in the region of the hub of the thrower wheel and then conveyed horizontally outward with the aid of the blades of the thrower wheel and delivered—through openings in the mechanical spreader stoker—into the combustion chamber. As already mentioned previo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com