Vertical reciprocating grate

A reciprocating grate, vertical technology, applied in the field of boiler grate, to achieve the effect of easy ignition, good combustion and low ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

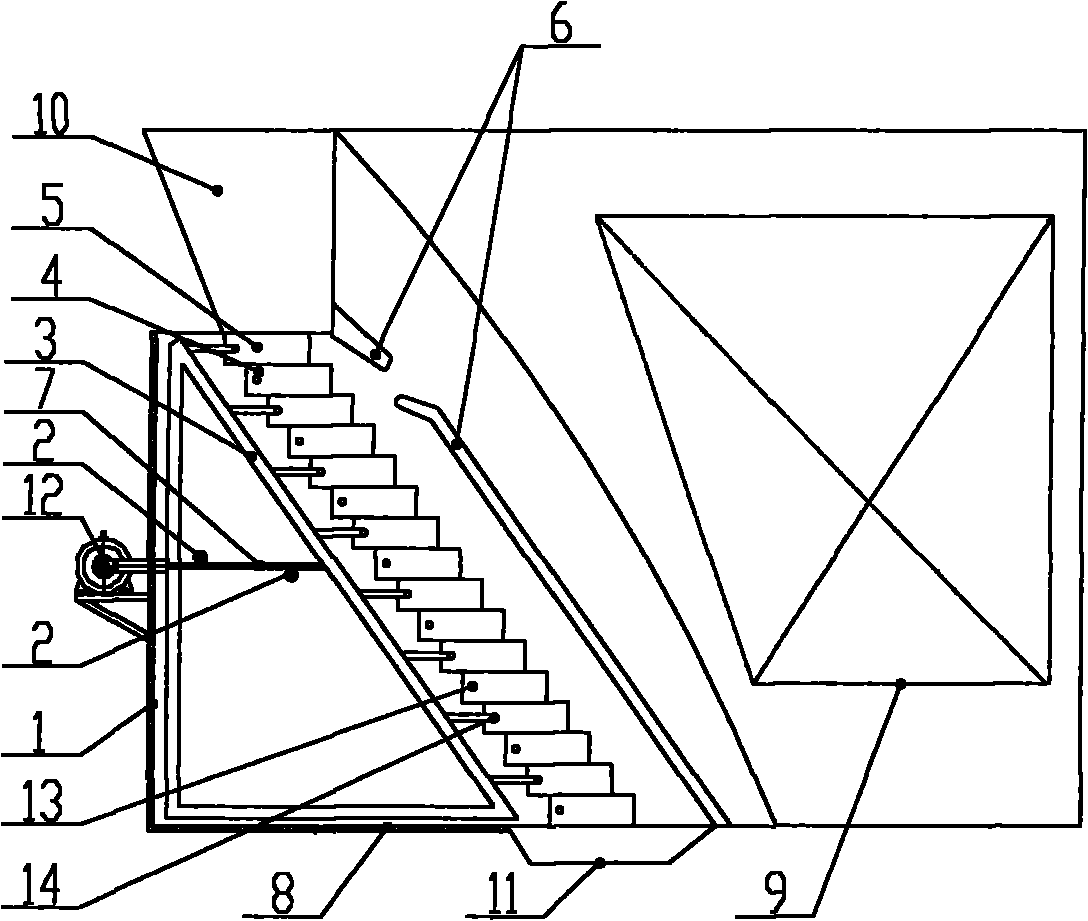

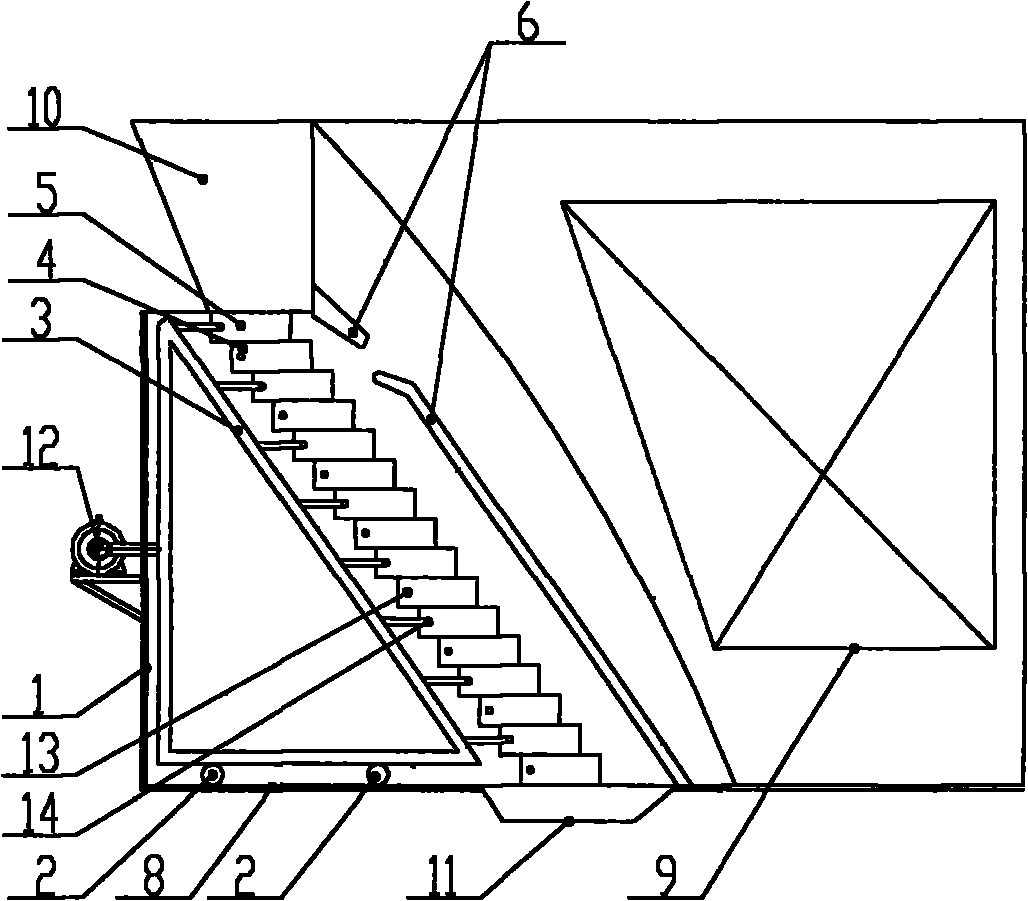

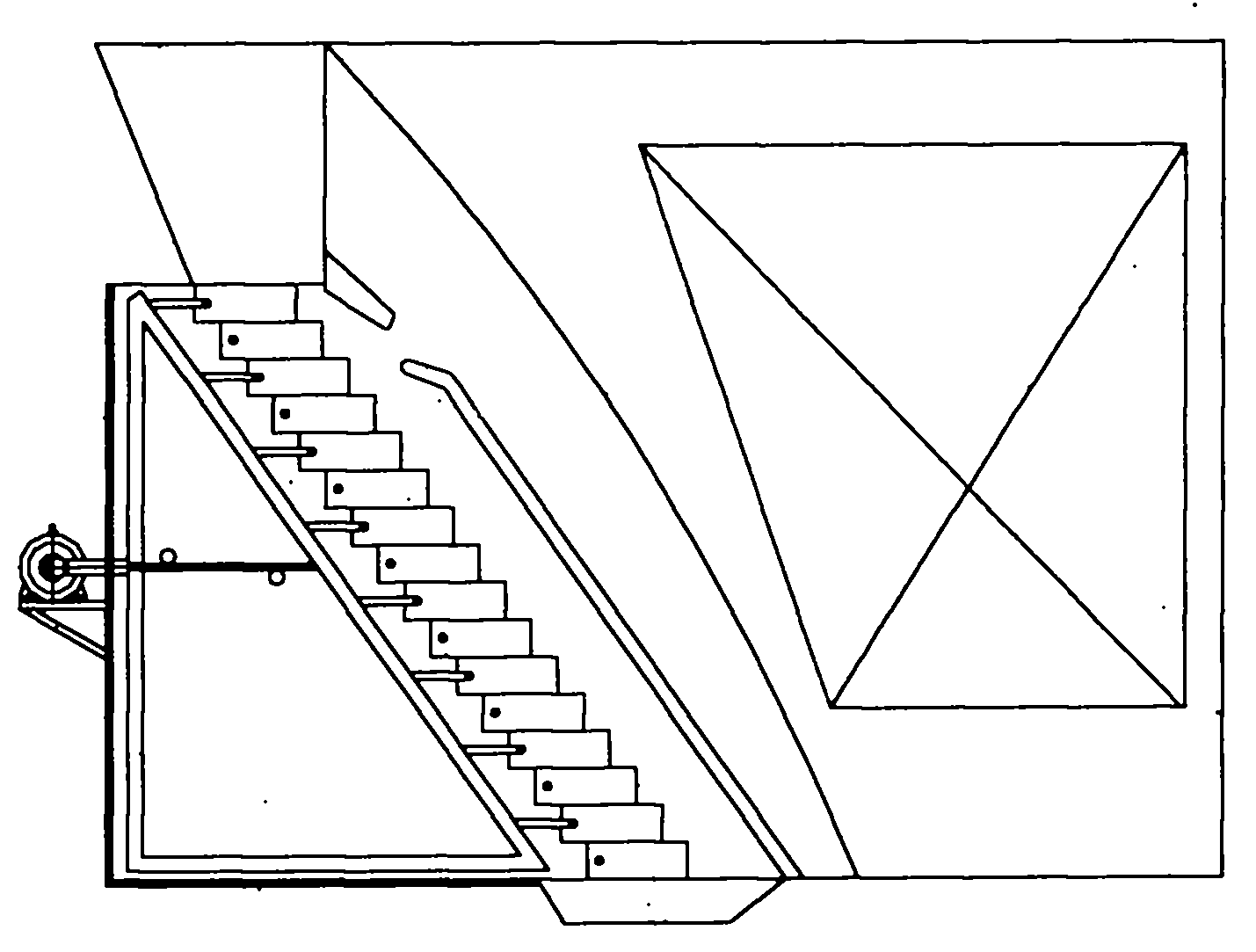

[0008] Provide preferred embodiment of the present invention below in conjunction with accompanying drawing: By figure 1 In the given embodiment, the vertical reciprocating grate is fixed on the fixed grate bracket 1, the movable grate bracket installation roller 2 on the left and right side walls of the fixed grate bracket 1, and the movable grate bracket 3. The fixed grate support 1 is composed of the fixed grate 4 on the grate installation beam, the movable grate 5 fixed on the movable grate support 3 and the reflective arch 6 on the grate installation beam, the fixed grate support 1 and the movable grate support 3 It is a vertical frame with a front slope angle greater than 35 degrees. The grate installation beams 13.14 on the fixed grate support 1 and the movable grate support 3 are distributed on the front slope, and the fixed grate 4 and the movable grate The working surface of the reciprocating fire grate formed by the strips 5 is stepped, and the reflective arch 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com