Slag driving device on side edge of zinc pot

A driving device and slag-removing technology, applied in coating, metal material coating process, hot-dip plating process, etc., can solve problems such as the influence of galvanizing quality on the surface of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

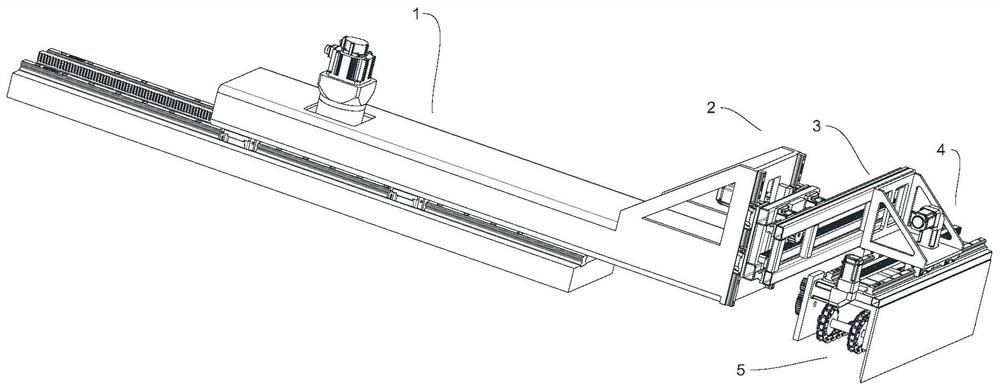

[0038] In this example, if figure 1 , Figure 9 with Figure 10 As shown, a slag removal device on the side of a zinc pot includes an axial translation mechanism 1, a lifting mechanism 2, a first lateral translation mechanism 3 and a slag removal mechanism 5, and the axial translation mechanism 1 is installed in the zinc liquid of the zinc pot In the axial direction of the pool 8, the end of the axial translation mechanism 1 near the center of the zinc liquid pool 8 is equipped with a lifting mechanism 2, and the side of the lifting mechanism 2 near the center of the zinc liquid pool 8 is equipped with a first lateral translation mechanism 3, the first The movement directions of the lateral translation mechanism 3 and the axial translation mechanism 1 are perpendicular to each other, and a slag removal mechanism 5 is installed on the side of the first lateral translation mechanism 3 close to the center of the zinc liquid pool 8 .

[0039]In this embodiment, in order to bette...

Embodiment 2

[0046] On the basis of the first embodiment, this embodiment provides an optional solution for the specific structure of the axial translation mechanism 1:

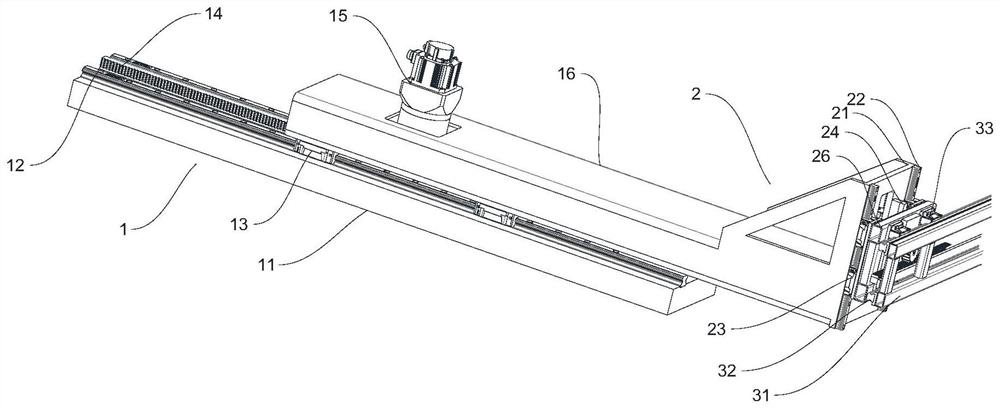

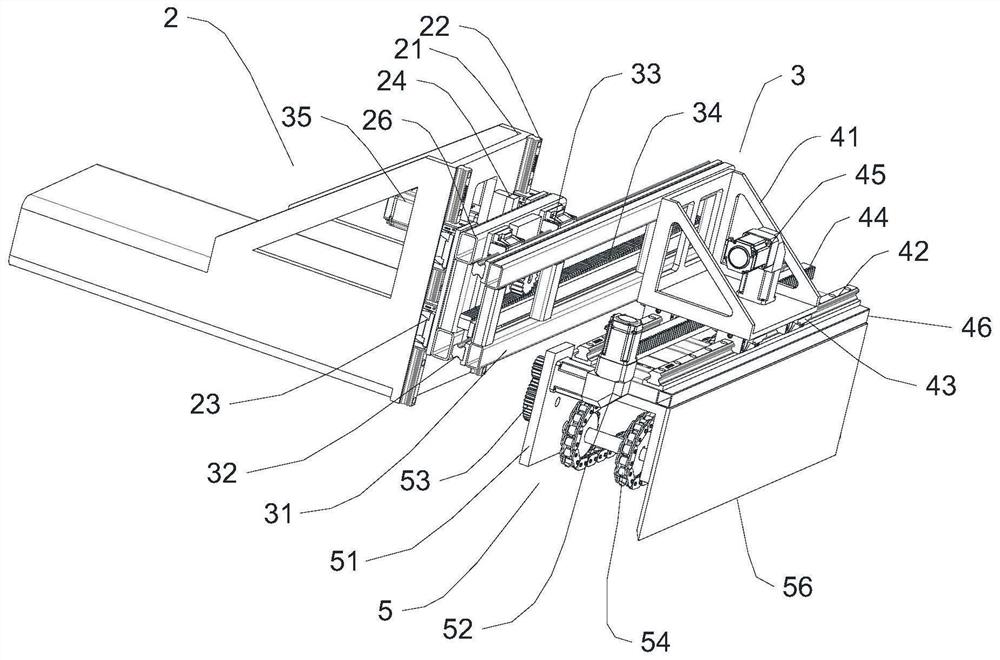

[0047] In this example, if figure 2 , Figure 4 , Figure 6 with Figure 8 As shown, the axial translation mechanism 1 includes a first mounting seat 11, a first slide rail 12, a first sliding member 13, a first driving device 15 and a first movable member 16, and the first mounting seat 11 is installed on the zinc liquid pool 8 One side of the first mounting base 11 is equipped with a first slide rail 12, the first slide rail 12 is installed along the axial direction of the zinc liquid pool 8, and a first slide member 13 is slidably installed on the first slide rail 12. The first movable part 16 is installed on the sliding part 13, the first driving device 15 is installed on the first movable part 16, the first driving device 15 drives the first sliding part 13 to slide along the first slide rail 12, the first movabl...

Embodiment 3

[0051] This embodiment provides an optional solution for the specific structure of the lifting mechanism 2 on the basis of any of the above-mentioned embodiments:

[0052] In this example, if Figure 2-8 As shown, the lifting mechanism 2 includes a second mount 21, a second slide rail 22, a second slider 23, a second rack 24, a second driving device 25 and a second movable part 26; the second mount 21 is vertically Installed on the end of the axial translation mechanism 1 near the zinc liquid pool 8, the second mounting base 21 is vertically installed with a second slide rail 22 near the zinc liquid pool 8, and the second slide rail 22 is slidably installed with a second Slider 23, the second movable member 26 is installed on the second slider 23, the second rack 24 is installed on the second movable member 26, the second rack 24 and the second slide rail 22 are located at the second mounting seat 21 and Between the second movable parts 26 and parallel to each other, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com