Automatic residue poking method and device for wind distribution plate of biomass circulating fluidized bed boiler

A technology of circulating fluidized bed and air distribution plate, which is applied in the field of automatic slagging of biomass circulating fluidized bed boiler air distribution plate, which can solve problems such as blockage of biomass boiler slag discharge pipe, improve fluidization effect and ensure stability Operation, safety and reliability, and the effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

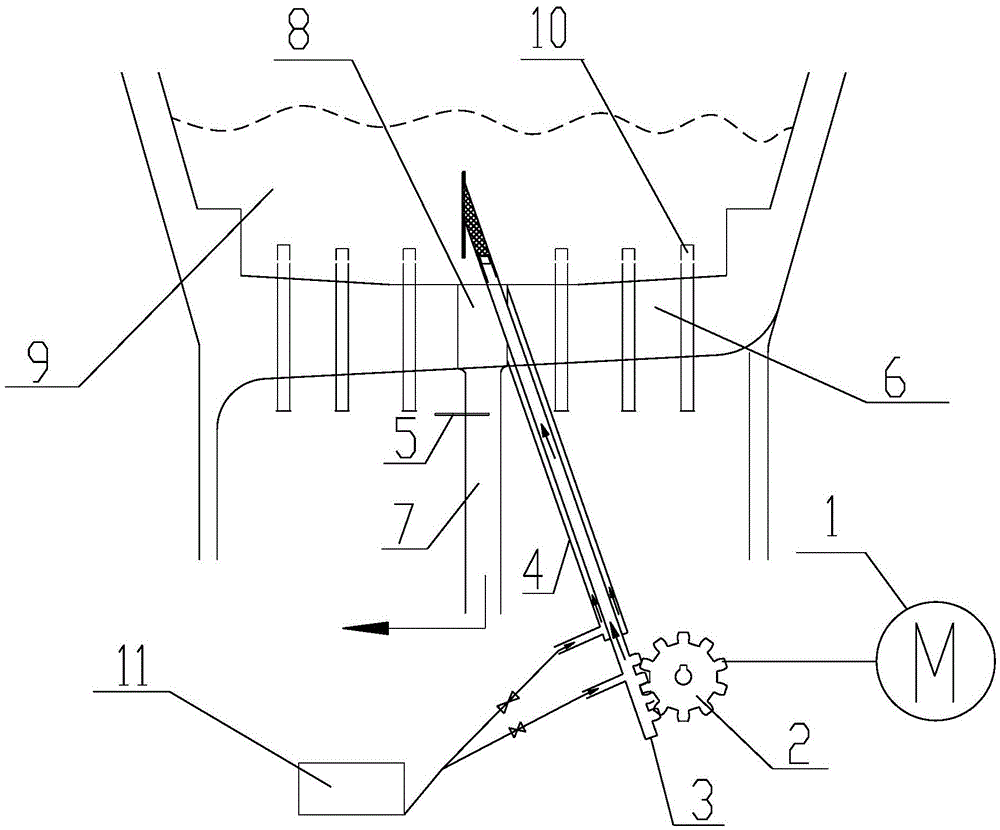

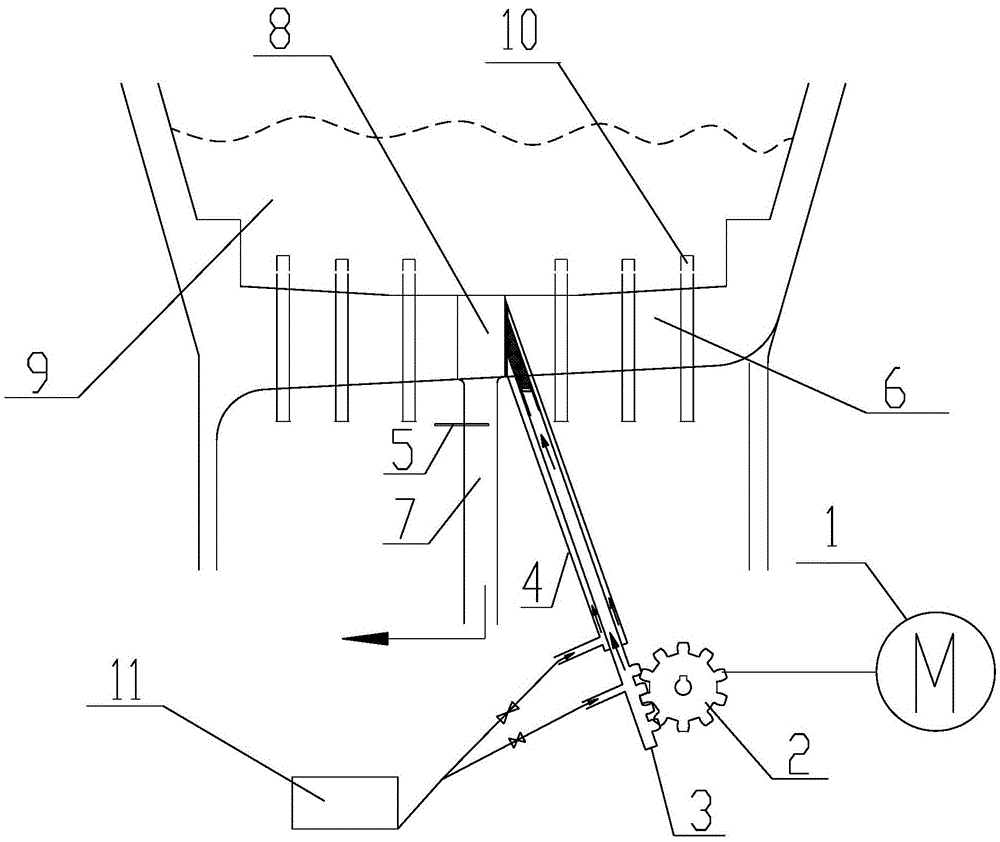

[0040] The device and method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

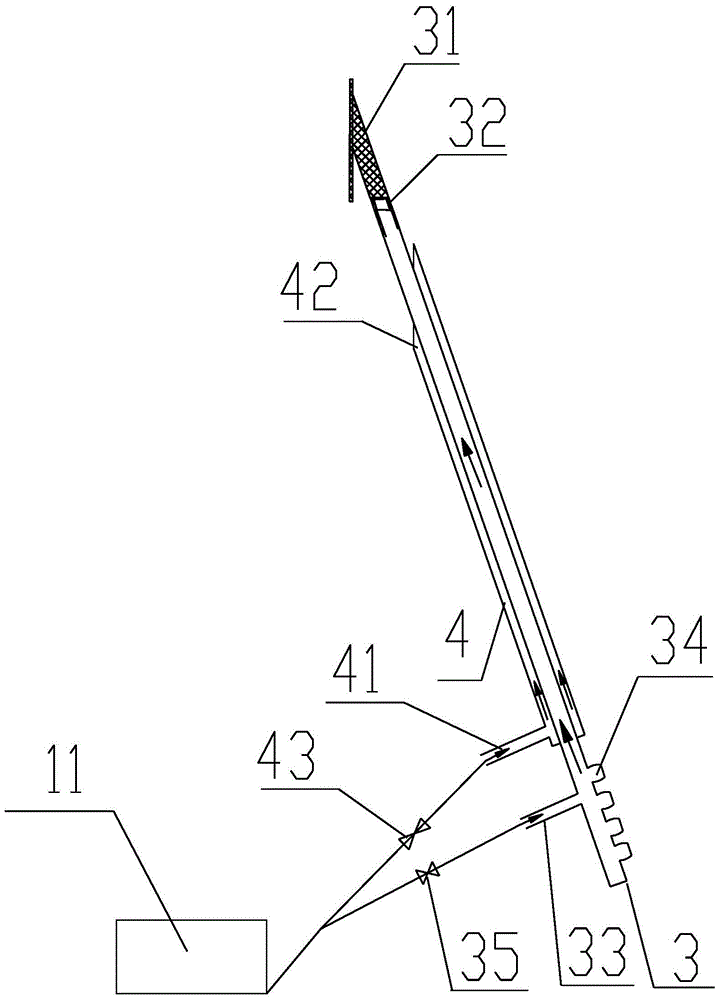

[0041] The automatic slagging device of the air distribution plate of the biomass circulating fluidized bed boiler shown in the figure is installed at the slag discharge hole 8 of the air distribution plate 6 of the boiler, on the side of the slag discharge pipe 7 below the slag discharge hole 8 . It has an outer sleeve 4 arranged obliquely to the slag discharge pipe 7. The inclination angle of the outer sleeve 4 relative to the slag discharge pipe 7 is about 22-24°. The side wall openings are connected as a whole, and its structure is simple and compact, occupying very little space.

[0042] Axially telescopic fluidizing air duct 3 is installed in the inner cavity of outer casing 4, and the upper end of the fluidizing air duct 3 is welded with a slag breaking head 31. The shape of the opening of the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com