Feeding combustion device with automatic residue elimination function

A technology of a combustion device and a feeding device, which is applied to solid heating fuels, lighting and heating equipment, household stoves/stoves, etc. Effects of low calorific value and extended selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

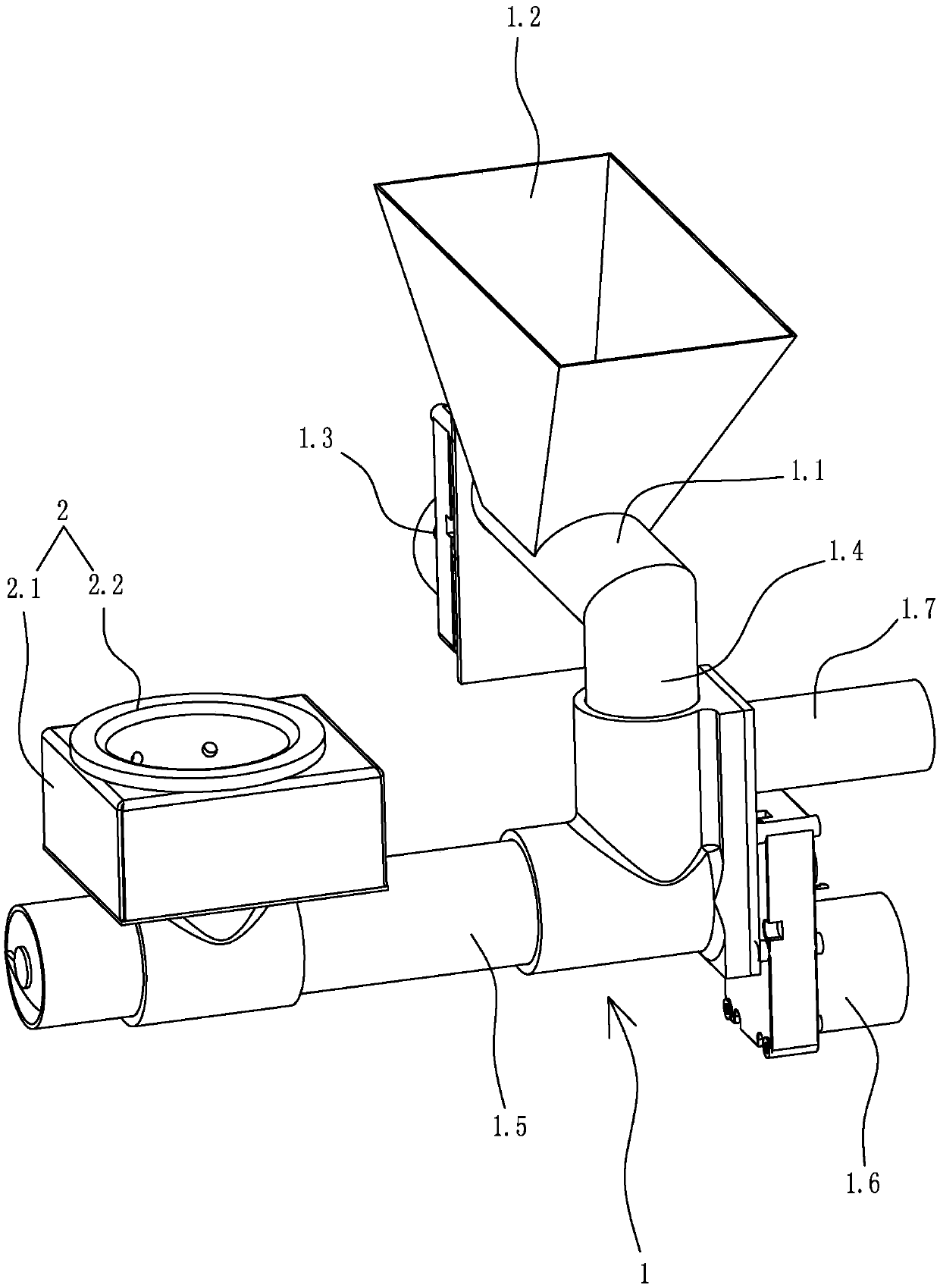

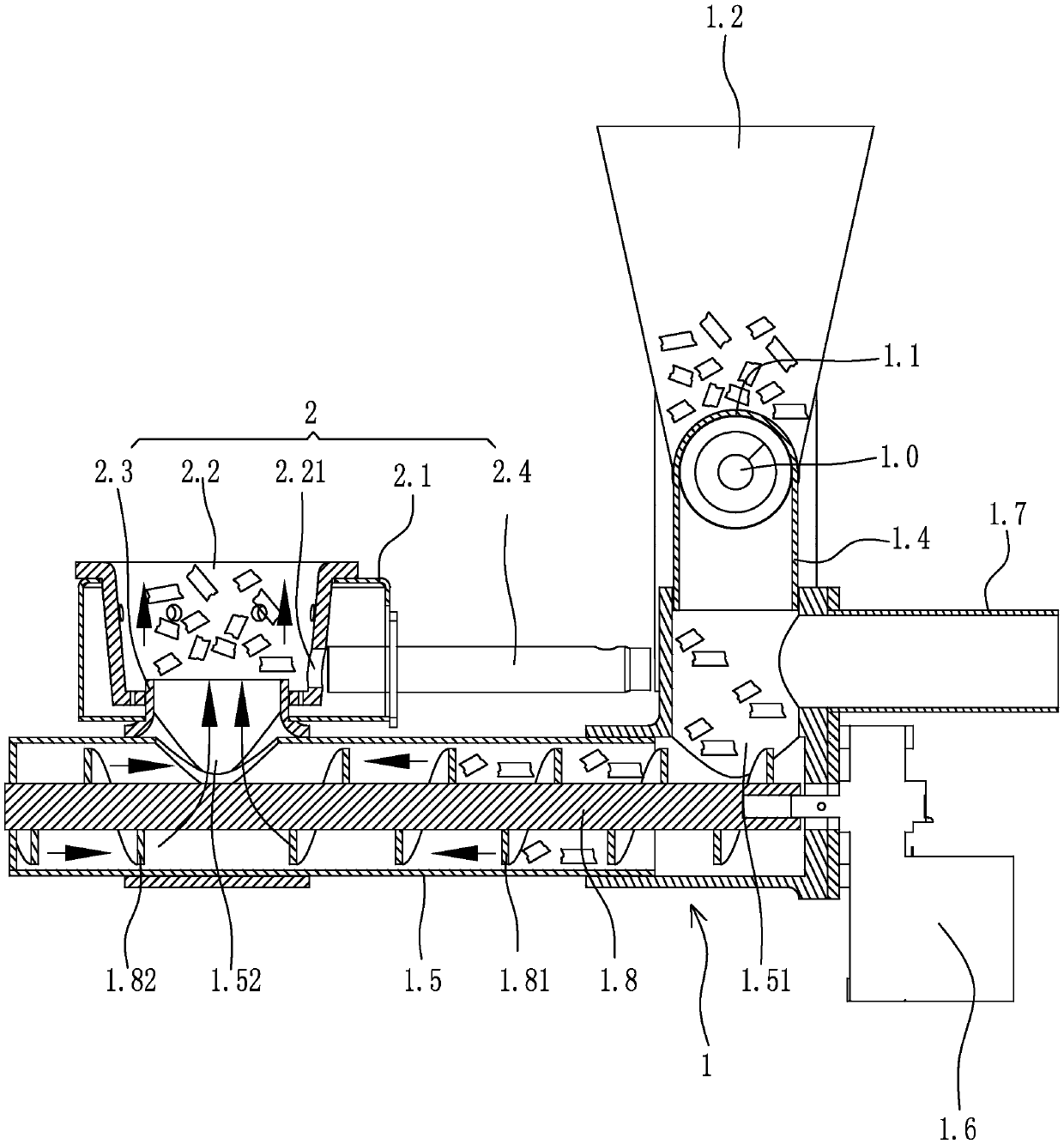

[0025] Specific embodiment one: as figure 1 , figure 2 As shown, an automatic slag cleaning and feeding combustion device includes a feeding device 1 and a combustion device 2 .

[0026] The feeding device 1 includes an upper feeding cylinder 1.1, a lower feeding cylinder 1.5, an air inlet pipe 1.7, an upper feeding auger 1.0 rotatingly arranged in the upper feeding auger, an upper driving motor 1.3 for driving the upper feeding auger, and an upper feeding auger arranged on the upper feeding auger. Feed hopper 1.2 on the outer surface of the cylinder, rotate the lower feeding auger 1.8 arranged in the lower feeding cylinder, the lower driving motor 1.6 for driving the lower feeding auger, and the lower feeding cylinder feeding port arranged on the outer surface of the lower feeding cylinder 1.51 and the lower feeding cylinder discharge port 1.52 that is arranged on the upward opening on the outer surface of the lower feeding cylinder.

[0027] The axis of the upper feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com