Slag removing machine for sword grid

The technology of a slag remover and a sword fence is applied in the field of slag removal, which can solve the problems of low slag removal efficiency and low degree of automation, and achieve the effects of reducing the labor intensity of operation, reducing labor intensity, and being easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

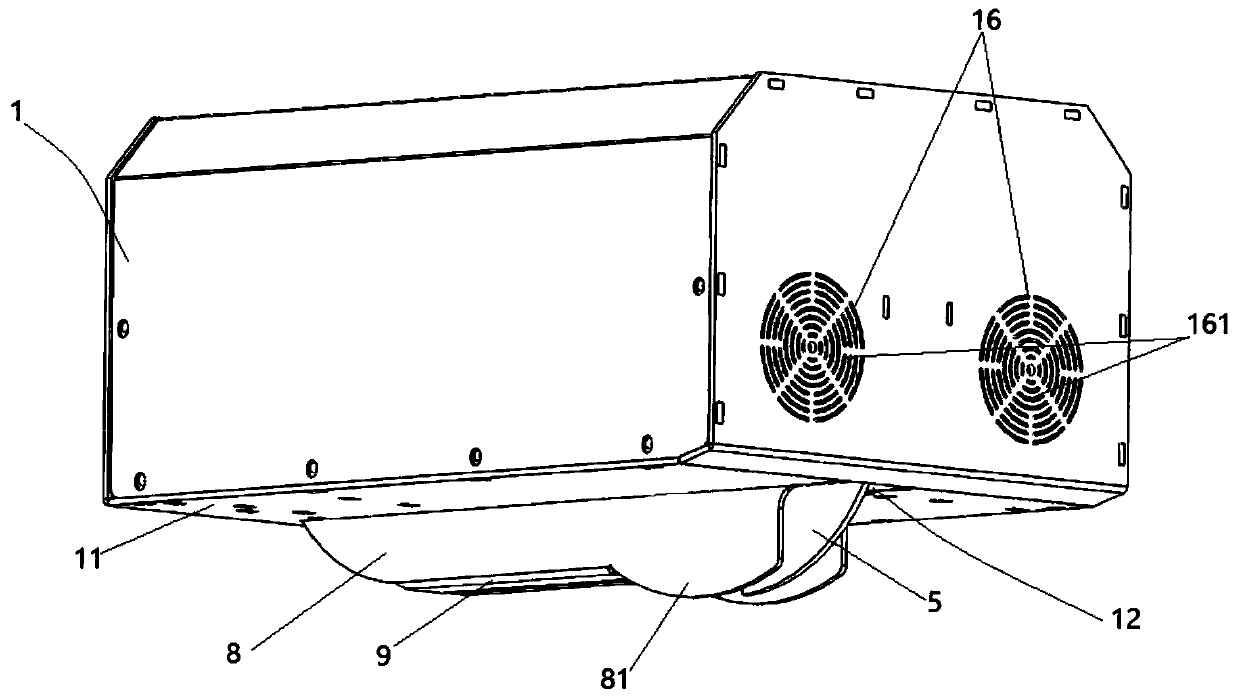

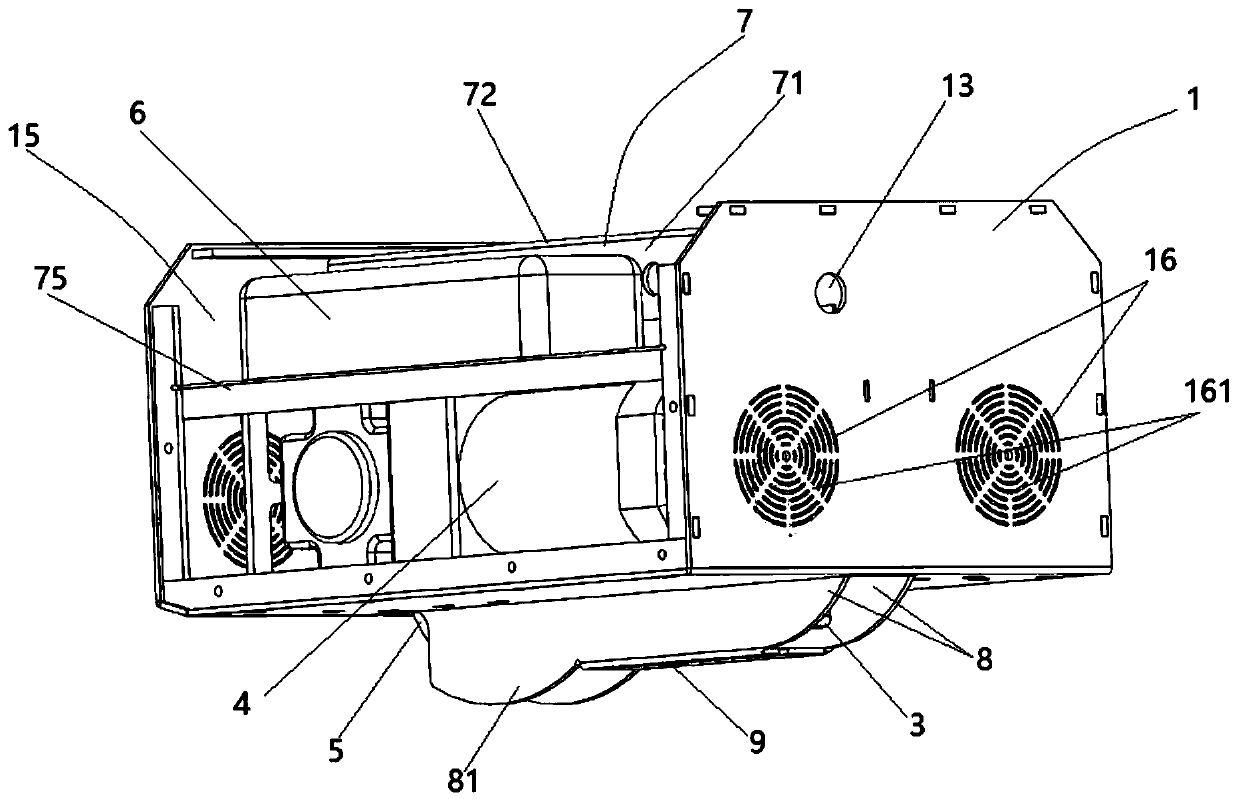

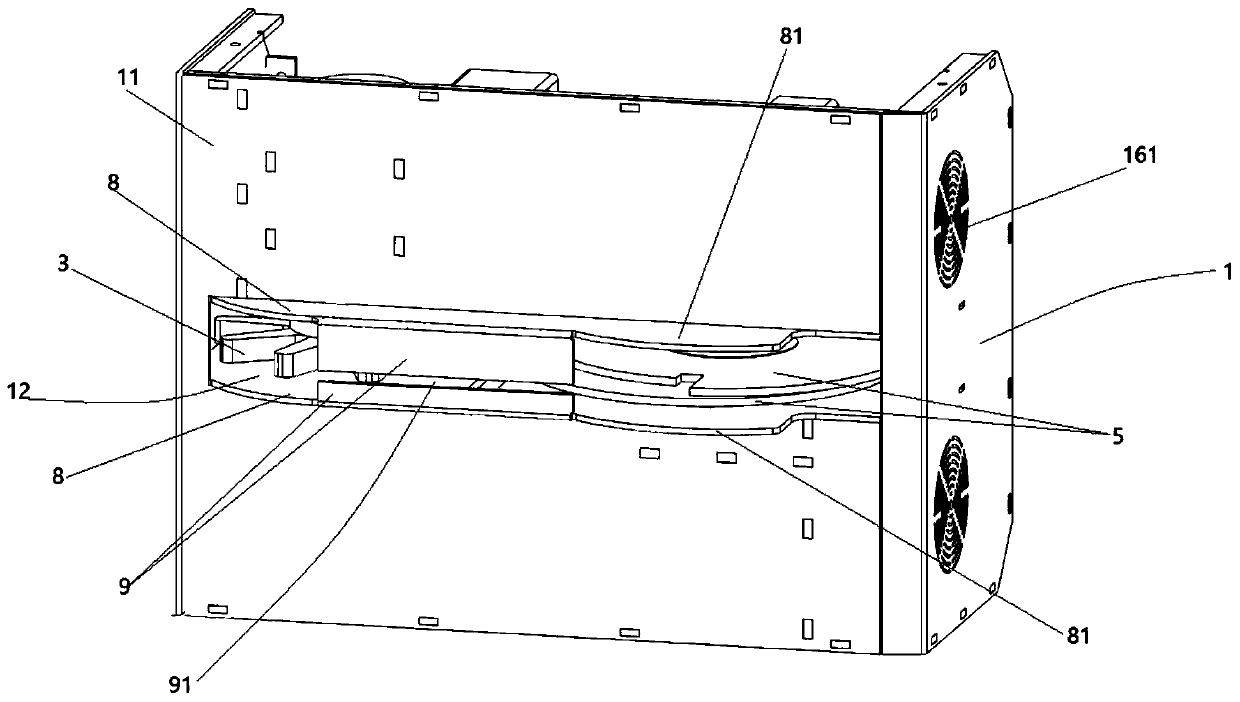

[0050] see Figure 1-7 , a sword grid slag removal machine provided by the present invention, the slag removal machine includes: a casing 1, which is a horizontally placed box, and a middle part of the bottom plate 11 of the casing 1 is opened along the running direction of the slag removal machine. The bar-shaped opening 12 corresponding to the sword rack (not shown), the width of the bar-shaped opening 12 is greater than the width of the sword rack, and the upper surface of the casing 1 is provided with a control opening (not shown), so There is a power supply opening 13 on the upper part of the side wall of the casing 1; the driving motor 2 is installed on the inner surface of the bottom plate 11 on the side of the strip opening 12, and the driving shaft 21 of the driving motor 2 extends to the corresponding slag removal machine. Above the strip-shaped opening 12 at the rear end of the direction; the driving gear 3 is vertically arranged and rotatably sleeved on the drive s...

Embodiment 2

[0070] The outer surface of the bottom plate 11 of the casing 1 located on both sides of the strip opening 12 is respectively protruded with a baffle 8 along the direction vertical to the bottom plate 11; the two baffles 8 are arranged along the running direction of the slag remover; One end close to the slag removal blades 5 protrudes outward to form a guard portion 81, and the two guard portions 81 cooperate to form protection for the two slag removal blades 5; the outer edge of the guard portion 81 of the baffle plate 8 is arc-shaped.

[0071] The distance between the protective parts 81 of the two baffles 8 is slightly larger than that of the two slag removal blades 5, and they are located outside the two slag removal blades 5. The slag removal blades 5 are wrapped inside by the protective parts 81 of the two baffle plates 8 during operation to protect the slag removal blades. The blade 5 is not damaged by other foreign objects, prolongs the service life of the slag removal...

Embodiment 3

[0074] The width direction of the two baffle plates 8 is connected to a guide plate 9 away from the ends of the bottom plate 11 respectively. The guide plate 9 is arranged vertically to the baffle plate 8. The guide plate 9 extends to the top of the strip opening 12 away from the end of the baffle plate 8. The guide plate 9 and the baffle plate 8 cooperate to form an L-shaped structure; a guide channel 91 is formed between the two guide plates 9, and the width of the guide channel 91 is greater than the width of the sword grid rack. The guide channel 91 cooperates with the driving gear 3 to form a A guide running along the length of the bar.

[0075] The guide channel 91 formed by the cooperation of the two guide plates 9 can ensure that the two slag removal blades 5 of the slag remover just fit the two side walls of the sword grid rack for slag removal operation, thereby ensuring the stability of the slag remover operation and ensuring efficient removal. scum.

[0076] All t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com