Auxiliary device for ship pipeline welding centering and method

An auxiliary device and pipeline technology, which is applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of difficult to control the alignment accuracy, low efficiency, and high labor intensity of manual operation, so as to improve the alignment accuracy. , The effect of high alignment efficiency and low operation labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

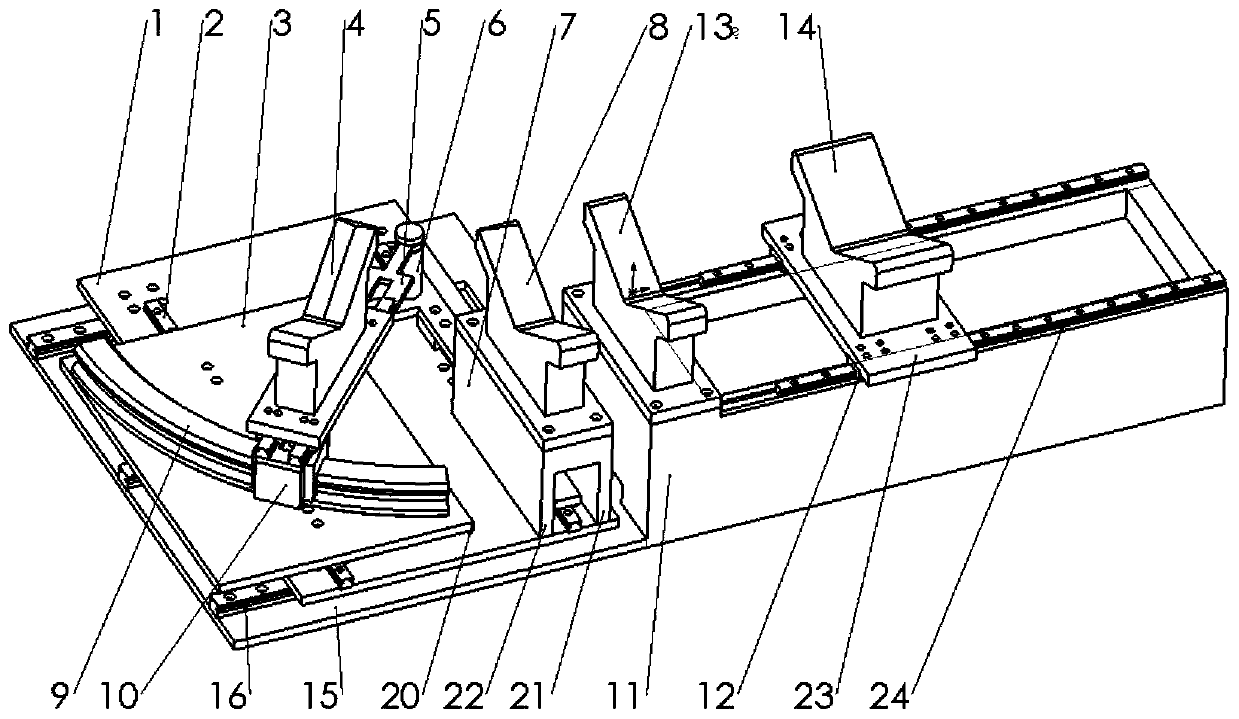

[0030] Now, the present invention will be further described in conjunction with the accompanying drawings of the description and specific implementation methods.

[0031] The overall structure of the centering auxiliary device of this implementation method is as follows: figure 1 Shown, including bent and straight sections.

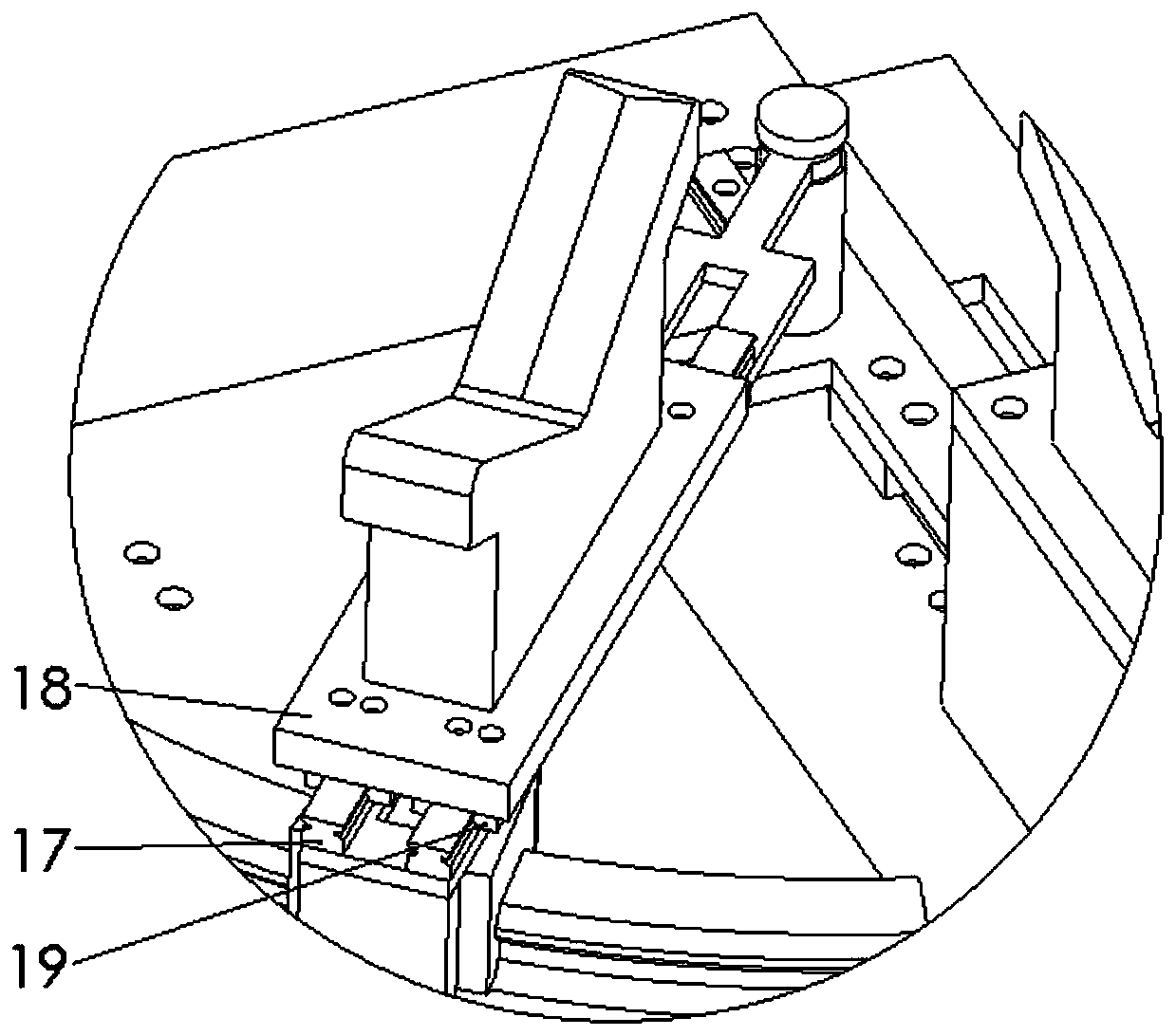

[0032] The elbow part is provided with a first V-shaped support block 4 and a second V-shaped support block 8 along the direction of the pipeline, and the first V-shaped support block 4 with two curved inner walls is fixed on the first fixed frame 18, and the first fixed frame 18 bottoms have slide block 19, and slide block 19 moves in the slide rail 17 on the rotating shaft guide rail frame 5, guarantees that the first V-shaped supporting block slides smoothly on the rotating shaft guide rail frame.

[0033] One end of the rotating shaft guide rail frame 5 is fixedly connected with an arc guide rail slider 10, and the other end is hinged with the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com