Method for removing free carbon in micro-silica fume by fluidized bed method

A technology of fluidized bed method and micro-silica fume, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of time-consuming, costly, and great influence on production capacity, and achieve the goal of reducing operation time and labor intensity and being easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

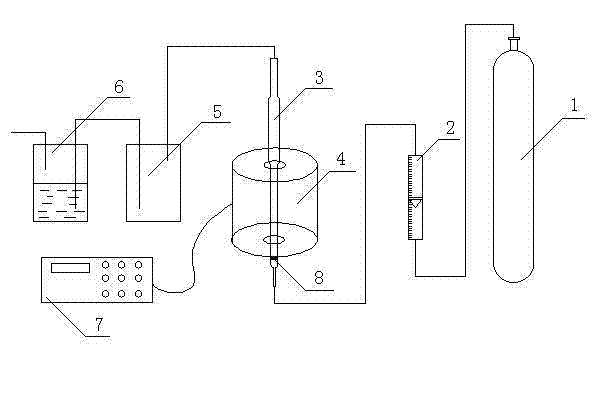

Image

Examples

Embodiment 1

[0011] Before opening the fluidized bed, carefully check whether the opening and closing of the switches and valves are correct; weigh 18g of micro-silicon powder raw material and place it in the fluidized bed reactor; control the amount of oxygen entering the reactor by adjusting the gas flow meter, so that the micro-silicon powder Reach the best fluidization state; turn on the heater, adjust the reaction temperature to 500°C, and the reaction time is 2.5 hours; after the reaction is completed, turn off the heating device and continue to feed oxygen, and stop feeding oxygen when the temperature drops to room temperature. The material taken out is the micro-silicon powder with free carbon removed.

Embodiment 2

[0013] Before opening the fluidized bed, carefully check whether the opening and closing of the switches and valves are correct; weigh 20g of micro-silicon powder raw material and place it in the fluidized bed reactor; control the amount of oxygen entering the reactor by adjusting the gas flow meter, so that the micro-silicon powder Reach the best fluidization state; turn on the heater, adjust the reaction temperature to 700°C, and the reaction time is 3.0h; after the reaction is completed, turn off the heating device and continue to feed oxygen, and stop feeding oxygen when the temperature drops to room temperature. The material taken out is the micro-silicon powder with free carbon removed.

Embodiment 3

[0015] Before opening the fluidized bed, carefully check whether the opening and closing of the switches and valves are correct; weigh 22g of micro-silicon powder raw material and place it in the fluidized bed reactor; control the amount of air entering the reactor by adjusting the gas flow meter to make the micro-silicon powder Reach the best fluidization state; turn on the heater, adjust the reaction temperature to 900°C, and the reaction time to 0.5h; after the reaction is completed, turn off the heating device and continue to supply air, and stop supplying air when the temperature drops to room temperature. The material taken out is the micro-silicon powder with free carbon removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com