Dynamic continuous organic solid waste gas-carbon oil cogeneration device

An organic solid waste and dynamic technology, applied in the fields of products, hydrocarbon oil treatment, petroleum industry, etc., can solve problems such as incomplete reaction, long reaction cycle, carbon deposition in equipment, etc., achieve convenient maintenance and management, increase stand-alone output, increase The effect of the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

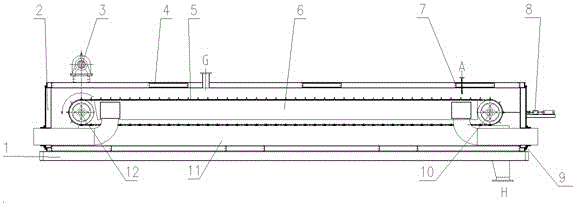

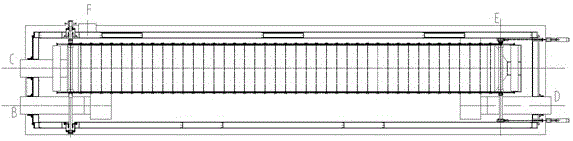

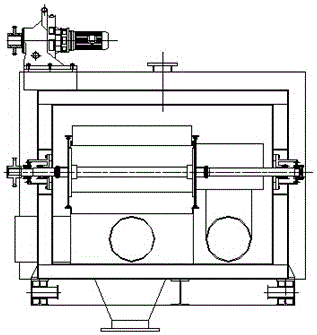

[0022] The first embodiment of the present invention provides a dynamic continuous organic solid waste co-production gas carbon oil device, see Figure 1-3 As shown, it includes a device body, which has a sealed reaction body structure composed of a main reactor box 4, and a first bed panel that is distributed in the cavity of the reaction body structure and can perform pyrolysis treatment on the object to be treated. 1. The second bed panel, the object to be treated in this article is molten fluid organic solid waste, the first and second bed panels are airtight hot air passage structures, and the first and second bed panels are respectively provided with their own hot air inlets. Outlet, for example, the first bed deck panel adopts as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com