A hydraulic cylinder with flexible vortex power, automatic slag removal and no backlog

An automatic cleaning and hydraulic cylinder technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of large piston starting resistance, backlog of damaged parts, oil residue wear and buffering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

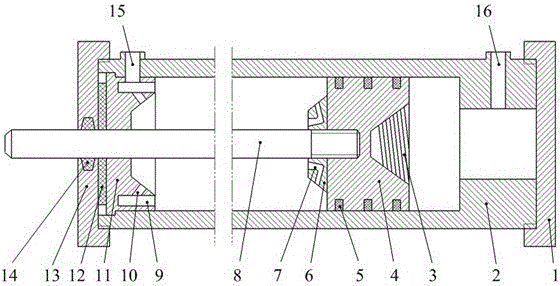

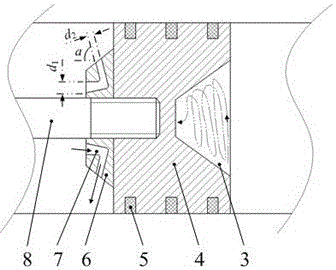

[0015] Such as figure 1 As shown, a flexible vortex power-assisted, automatic slag-cleaning and no backlog type hydraulic cylinder of the present invention mainly includes a cylinder barrel 2, an end cover, a piston rod 8, a piston 4, a buffer block 6, a guide sleeve 11 and a buffer pad 12 , the end cover is divided into end cover A 1 and end cover B13, the piston 4 and the buffer block 6 are installed on the piston rod 8 in turn through threaded connection, the guide sleeve 11, the buffer pad 12 and the end cover B 13 are installed on the piston rod 8 in turn side. Both ends of the cylinder 2 are provided with external threads, and the same side of the cylinder 2 is provided with an oil port B 15 and an oil port A 16 . The end cap A 1 and the end cap B 13 are respectively provided with internal threads, and are mounted on the cylinder 2 , and the middle part of the end cap B 13 has a through hole and a dust-proof ring 14 is installed therein. One end of the piston rod 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com