Fermentation machine with residue removing function

A technology of fermentation machine and function, applied in the field of fermentation machine with slag removal function, can solve the problems of too many slag bodies and poor taste of fermented food, and achieve the effect of good taste and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

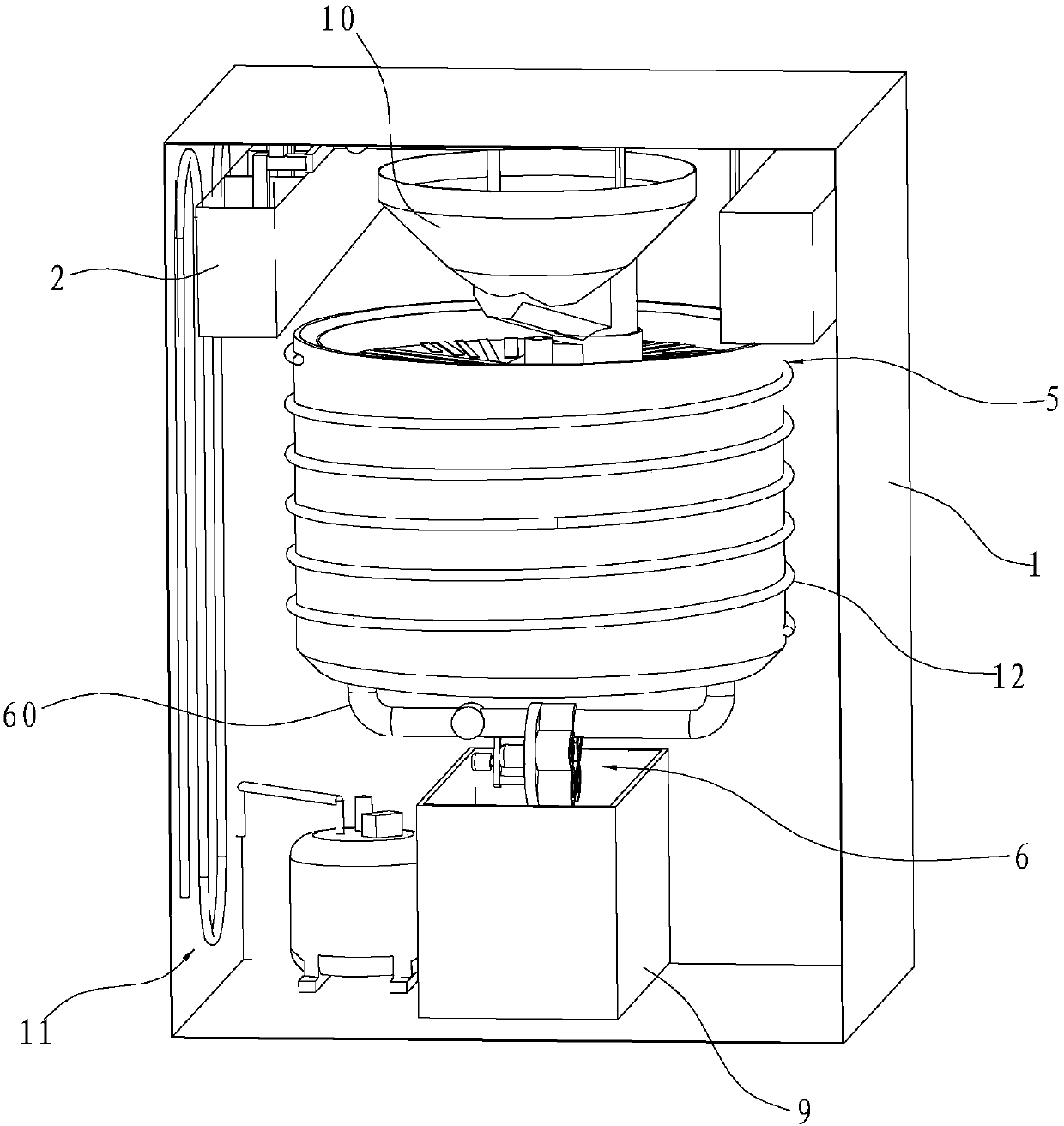

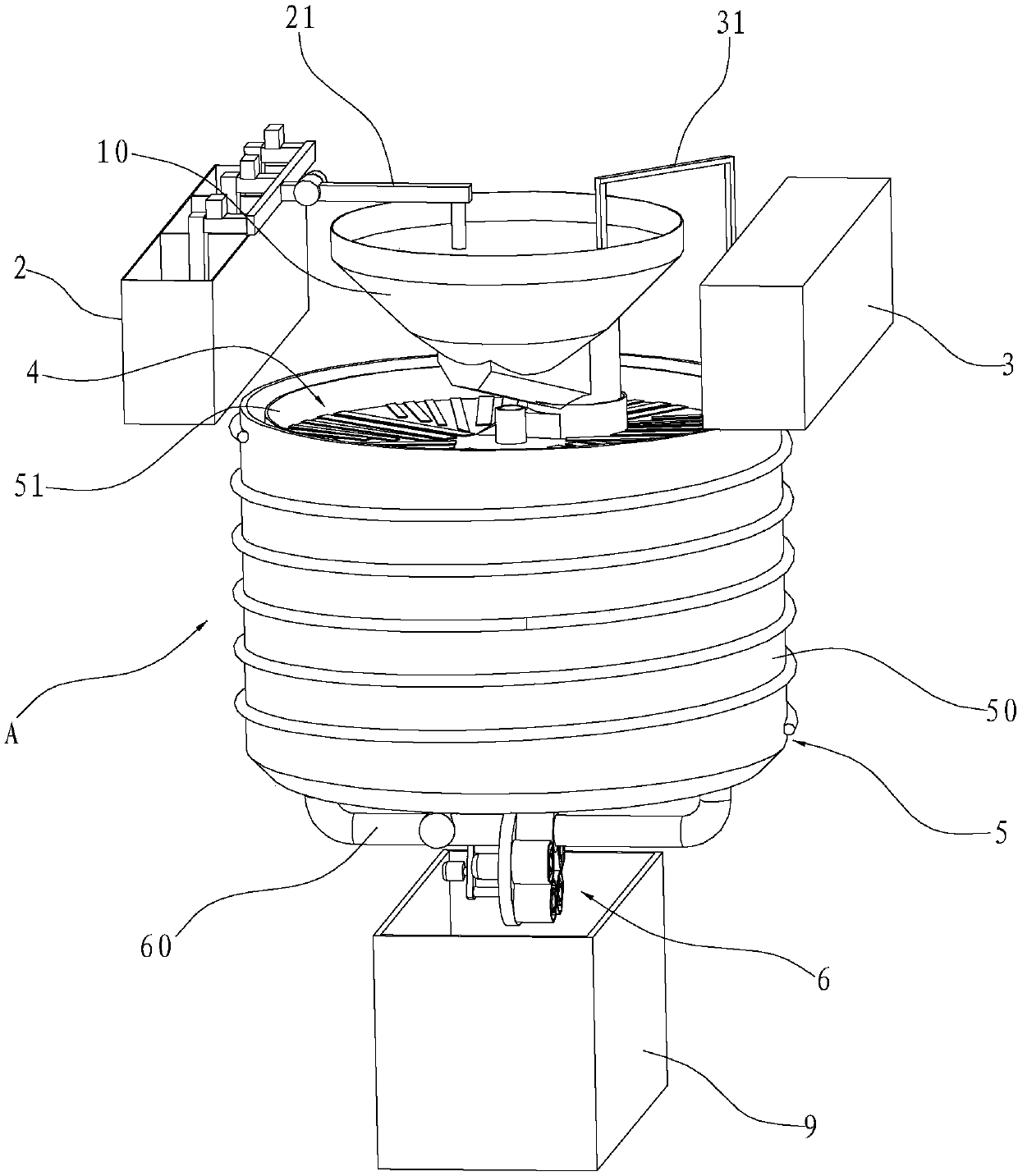

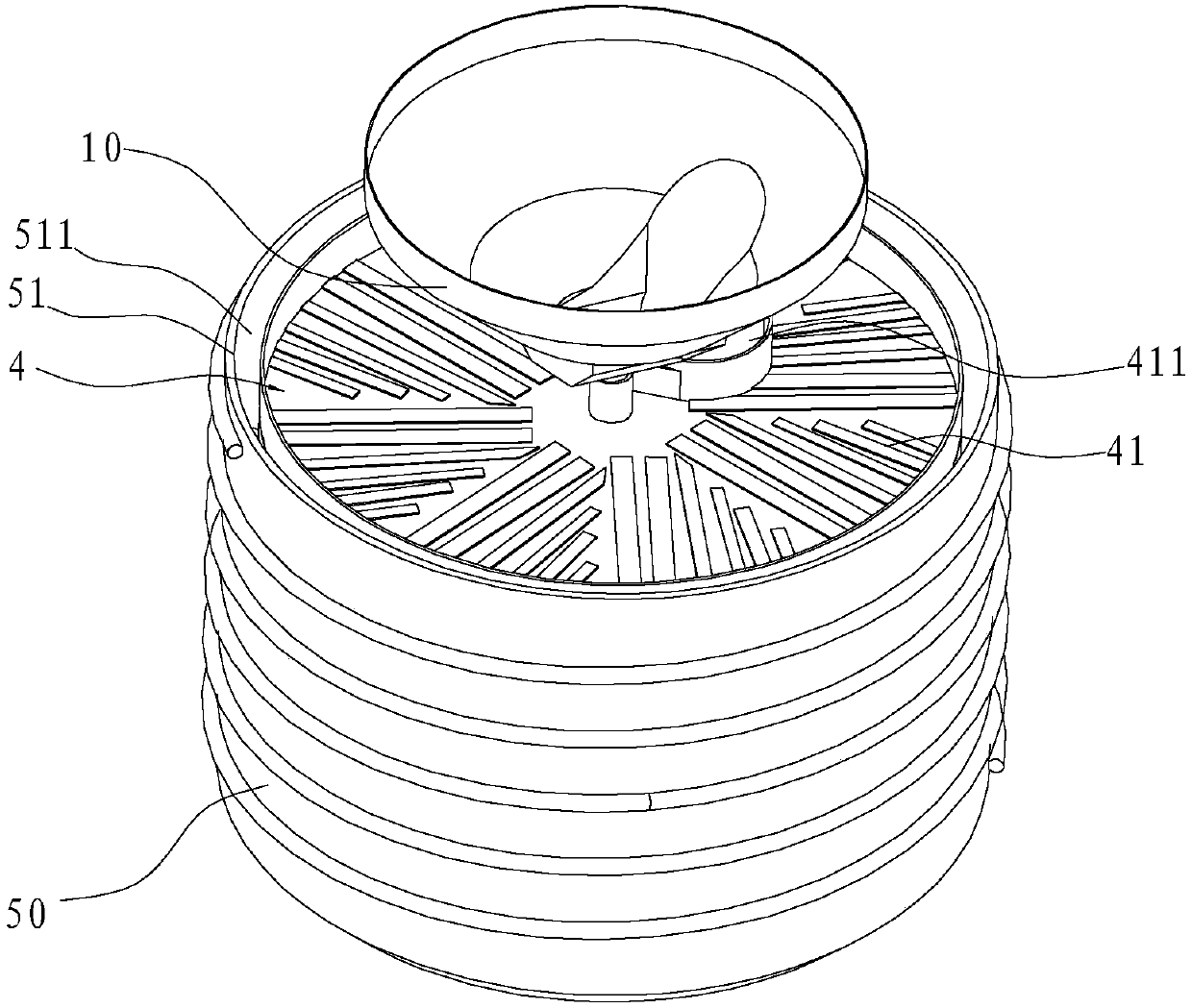

[0025] Such as Figure 1-11 As shown, a fermenter with a slag removal function includes a casing 1 in which a milling device 4, a fermenter 5, a water tank 3 and a strain box 2 are arranged, and the casing 1 is provided with a refrigeration assembly 11, and the fermenter 5 is provided with a heating assembly 12. By setting the milling device 4 and the fermenter 5 in the fermentation machine, after the raw materials such as fruits and vegetables required for fermentation are milled by the milling device 4, the juice can enter the fermenter 5 for fermentation, that is, the fermenter has basic fermentation functions. On the basis of it, it also has the function of grinding, and the functions are more diversified. When in use, the user does not need to manually cut and grind raw materials such as fruits and vegetables, which is more convenient t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com