Three-dimensional positioning method for automatic slagging-off of desulfurized molten iron

A technology of three-dimensional positioning and desulfurization of molten iron, applied in the field of metallurgy, can solve the problems of different, prolonged production cycle, unstable slag removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

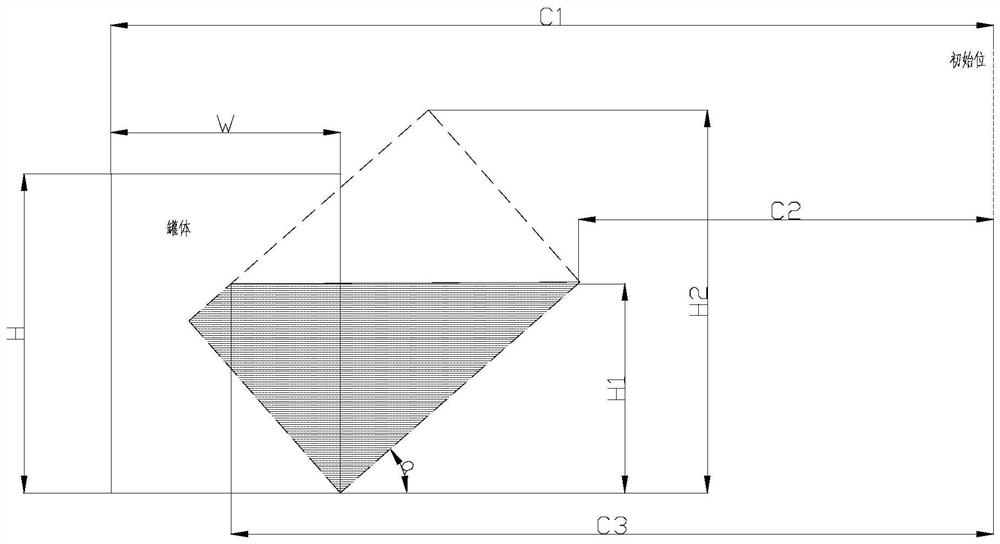

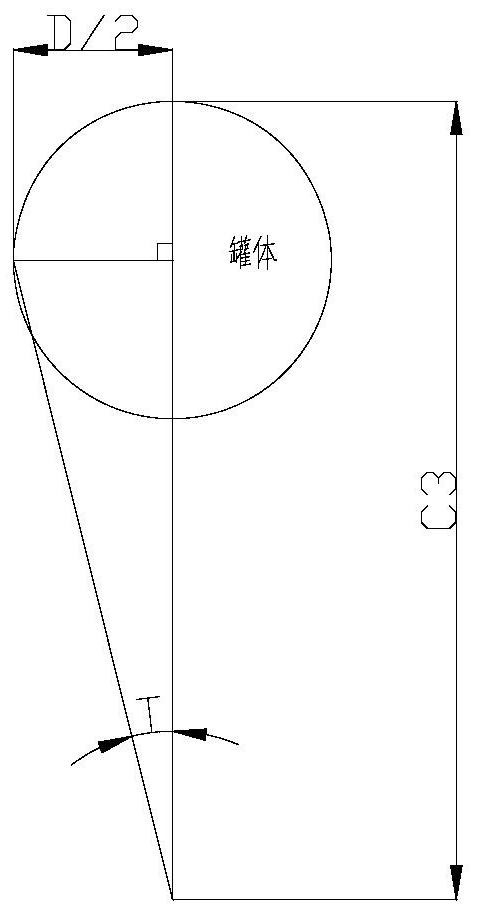

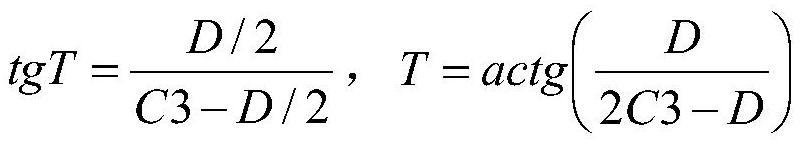

[0028] Such as figure 1 As shown, a three-dimensional positioning method for automatic slag removal of desulfurized molten iron comprises the following steps:

[0029] Step 1. Establish the original data model

[0030] 3) Calculate the minimum lifting height H1 and the maximum lifting height H2 of the slag remover

[0031] Install a set of encoders to measure the inclination angle of the molten iron tank on the output shaft of the reducer of the tank body of the molten iron car, tilt the molten iron tank to the position where the molten iron can be slag removed, and the angle acquisition value of the tank inclination angle encoder is fed back into the first-level PLC calculation The height of the molten iron level H1, that is, the minimum lifting height of the slag picker H1:

[0032] Minimum lifting height: H1=H sinα

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com