Conical ash control valve with automatic slag poking function

A technology of ash control valve and function, applied in the field of conical ash control valve, which can solve the problems of affecting the normal use of the ash (slag) discharge port, burns, and high labor intensity of on-site operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

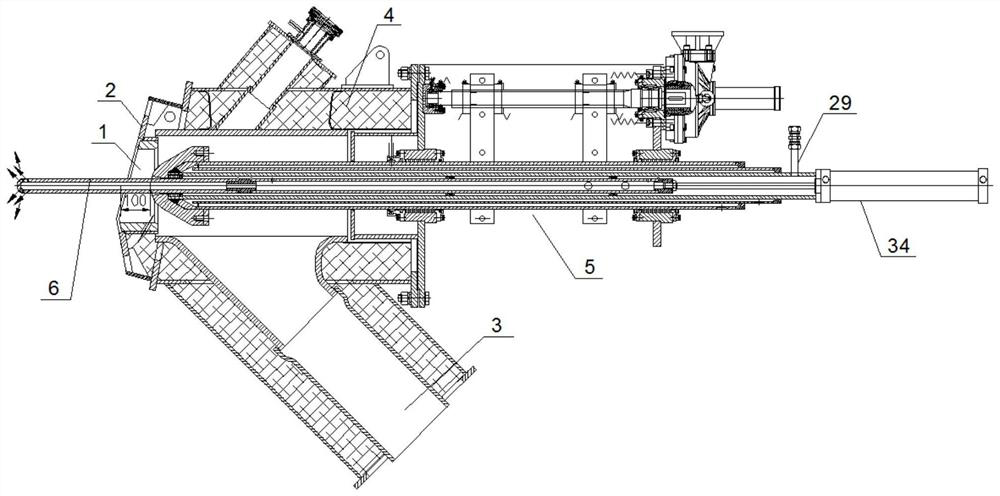

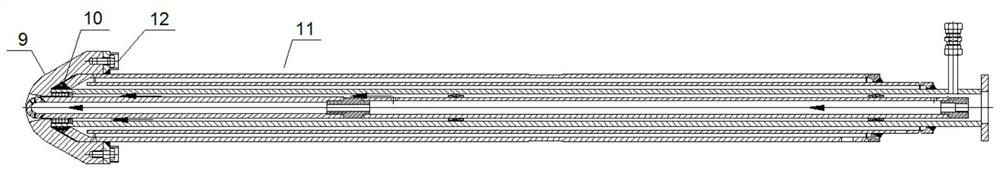

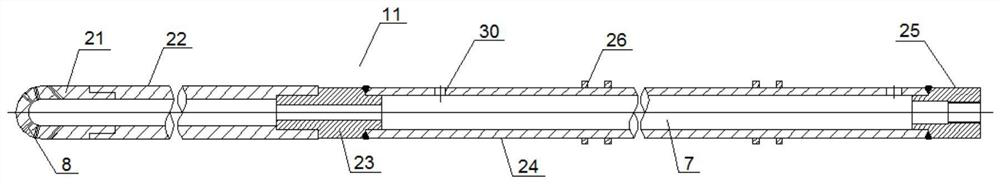

[0030] Such as Figure 1 to Figure 6 As shown, a cone-shaped ash control valve with automatic slagging function includes a valve seat 2 provided with a boiler slagging outlet 1 and a valve body 4 provided with an ash control valve outlet 3, and also includes a valve stem 5 and The slagging rod 6, the valve rod 5 is slidably installed in the valve body 4, the boiler slag outlet 1 is located on the moving path of the valve rod 5, the slagging rod 6 is installed in the valve rod 5, and the slagging rod 6 can be Moving along the axis of the valve rod 5, the slag breaking rod 6 breaks the massive material in the boiler slagging outlet 1 by stretching back and forth. A plurality of purge holes 8 communicated with the compressed air channel 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com