Corrosion-prevention and compression-resistant lithium battery shell and production method therefor

A production method and lithium battery technology, applied in the direction of lithium batteries, battery boxes/coats, battery pack parts, etc., can solve the problems of poor external moisture and oxygen barrier properties, poor corrosion resistance and electrical insulation, and great discomfort Capacity power lithium battery and other issues, to achieve superior electrolyte corrosion resistance, improve service life, enhance insulation reliability and corrosion resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

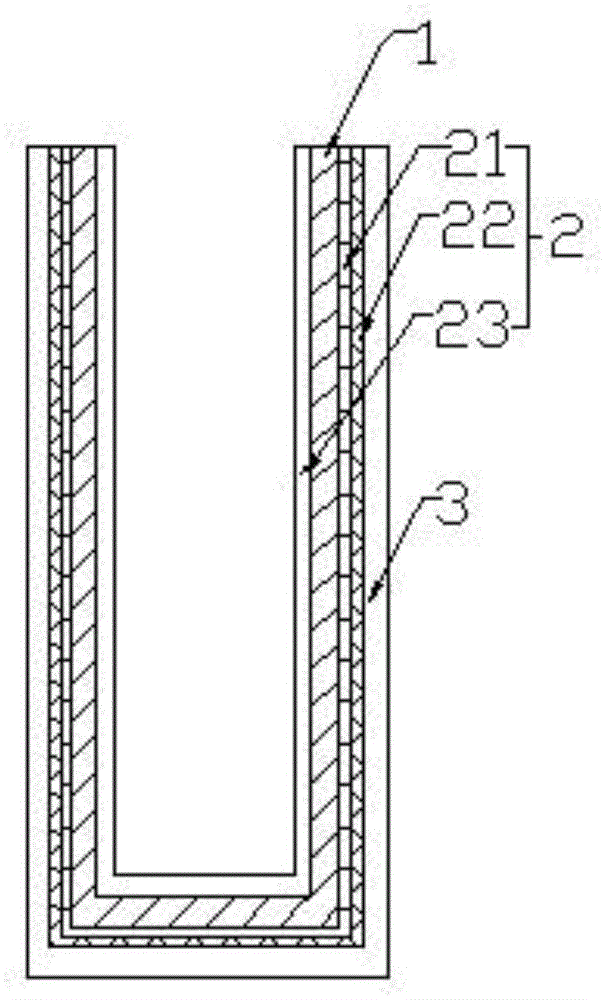

Image

Examples

Embodiment 1

[0018] The production method of the above-mentioned anticorrosive and pressure resistant lithium battery casing is as follows:

[0019] The first step: Surface pretreatment: First, perform sandblasting pretreatment on each surface of the main part of the battery case made of aluminum layer 1, polish and deburr the surface of the workpiece, to avoid uneven coating in the later stage, and pass the acceptance After that, proceed to the next step;

[0020] The second step: cleaning, activation: the workpiece after the previous step is cleaned, dehydrated, and then dried to clean the oil and other impurities on the surface of the workpiece; then the surface of the dried workpiece is coupled The activator is used as an activator for activation treatment; after acceptance, proceed to the next step;

[0021] The third step: Mask: stick tape or apply a proper amount of glue on the surface of the workpiece processed in the previous step. After standing for 0.5-1 hour, check whether there is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com