Automatic-rotating barbecue

A technology of automatic rotation and barbecue grill, which is applied in baking devices, roasters/barbecue grids, kitchen utensils, etc., can solve the problems of high labor intensity and inconvenience of grilling, and achieves reduction of labor intensity, improvement of comfort, and reduction of quilts. The effect of the probability of scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

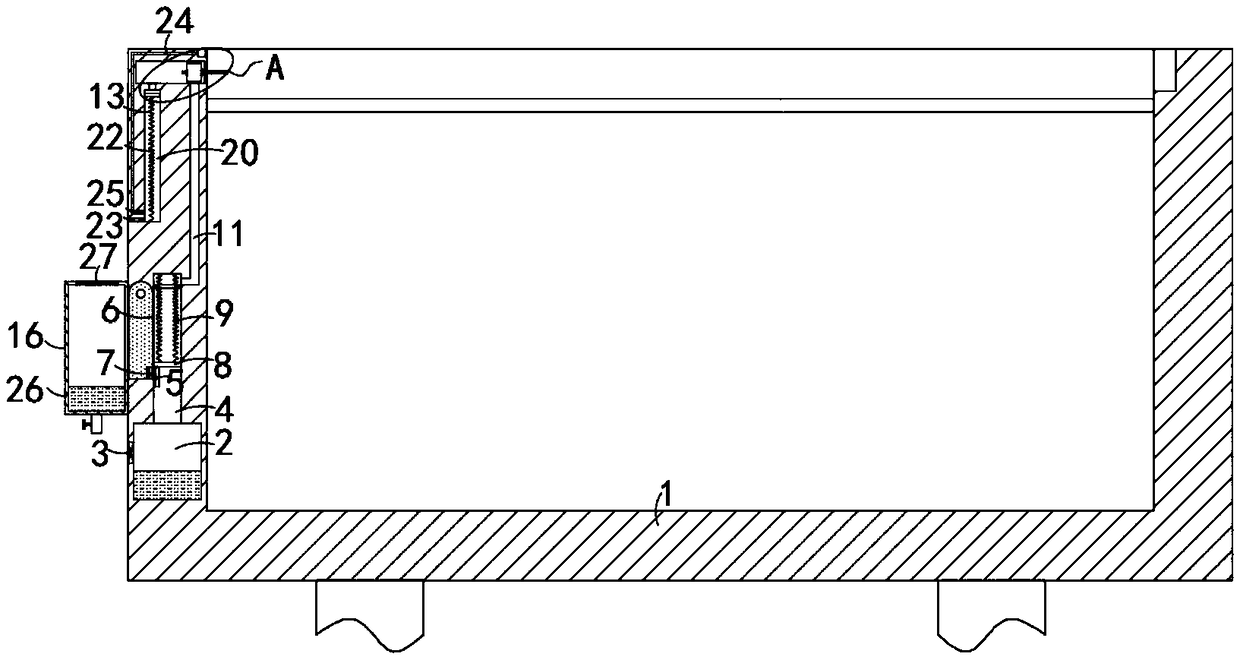

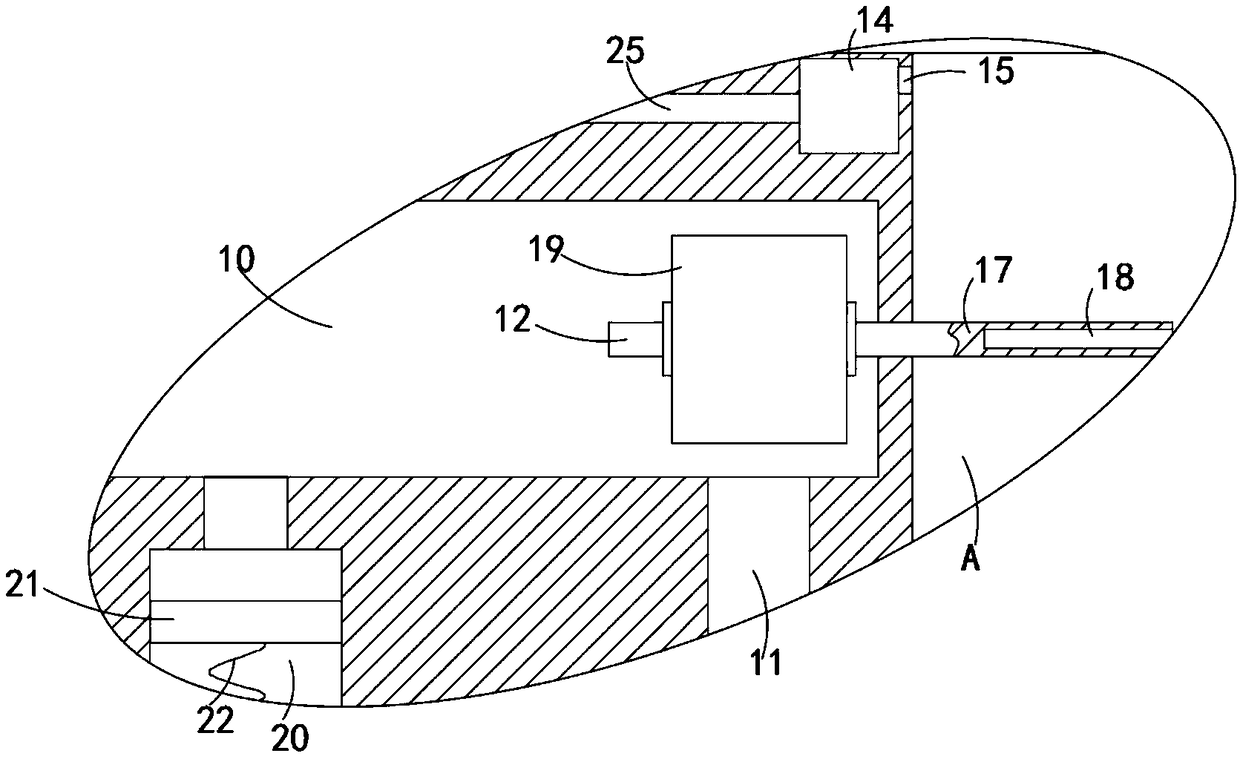

[0025] Such as Figure 1-4 As shown, a self-rotating barbecue grill includes a frame body 1. A first chamber 2 is arranged in one end side wall of the frame body 1. Evaporation liquid is stored at the bottom of the first chamber 2. The side of the first chamber 2 There is a feeding port on the wall, and the first sealing plate 3 is filled in the feeding port, wherein the first sealing plate 3 is opened by hand, so as to facilitate the addition of evaporating liquid into the first chamber 2, and the evaporating liquid is made of vinegar. Its boiling point is low, and it is easy to be heated and evaporated into gas. The top surface of the first chamber 2 is vertically provided with a plurality of first air guide holes 4, and the inner wall of the first air guide holes 4 is fixedly connected with a first magnet 5. The side wall of the air guide hole 4 is provided with a gas leak port, and the top surface of the gas leak port is rotatably connected with a second sealing plate 6, a...

Embodiment 2

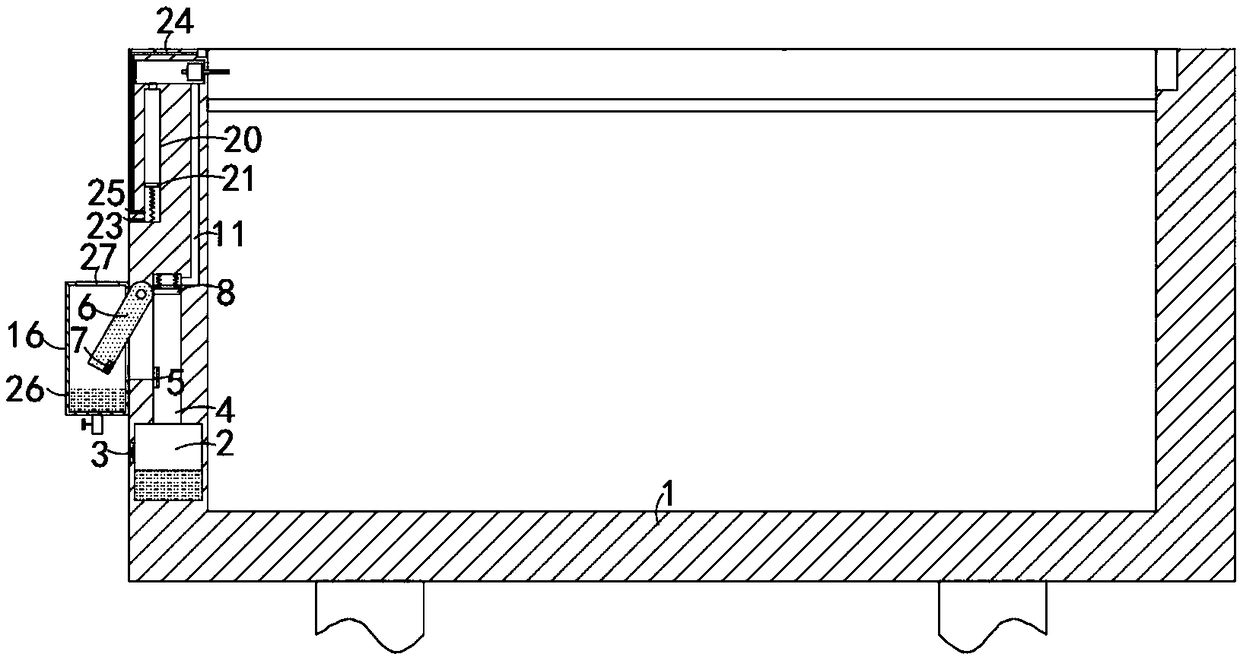

[0031] Such as Figure 5-7 As shown, the difference between this embodiment and Embodiment 1 is that: a third magnet 28 is installed on the upper end of the second piston plate 21, and an annular fourth chamber 29 is arranged in the frame body 1, and the fourth chamber 29 is arranged with the first magnet. Outside the three air guide holes 20, a plurality of coils 30 are installed in the fourth chamber 29, and bulbs 31 corresponding to the coils 30 are installed on the side wall of the frame body 1, and the bulbs 31 are coupled with the coils 30, wherein the frame body 1. Except the side wall provided with the water tank 26, bulbs 31 are installed on the other side walls. Since the water tank 26 has the function of anti-scalding, people stand near one end of the water tank 26 during operation.

[0032] When this embodiment is in use, because the second piston plate 21 will reciprocate in the vertical direction when the frame body 1 is grilling, it can then drive the third magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com