Open mill

An open mill and rack technology, which is applied in the field of artificial leather production equipment, can solve the problems of hidden safety hazards and high labor intensity, and can reduce the probability of being stuck on the guide wheel, reduce labor intensity, and reduce the probability of hand being scalded. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

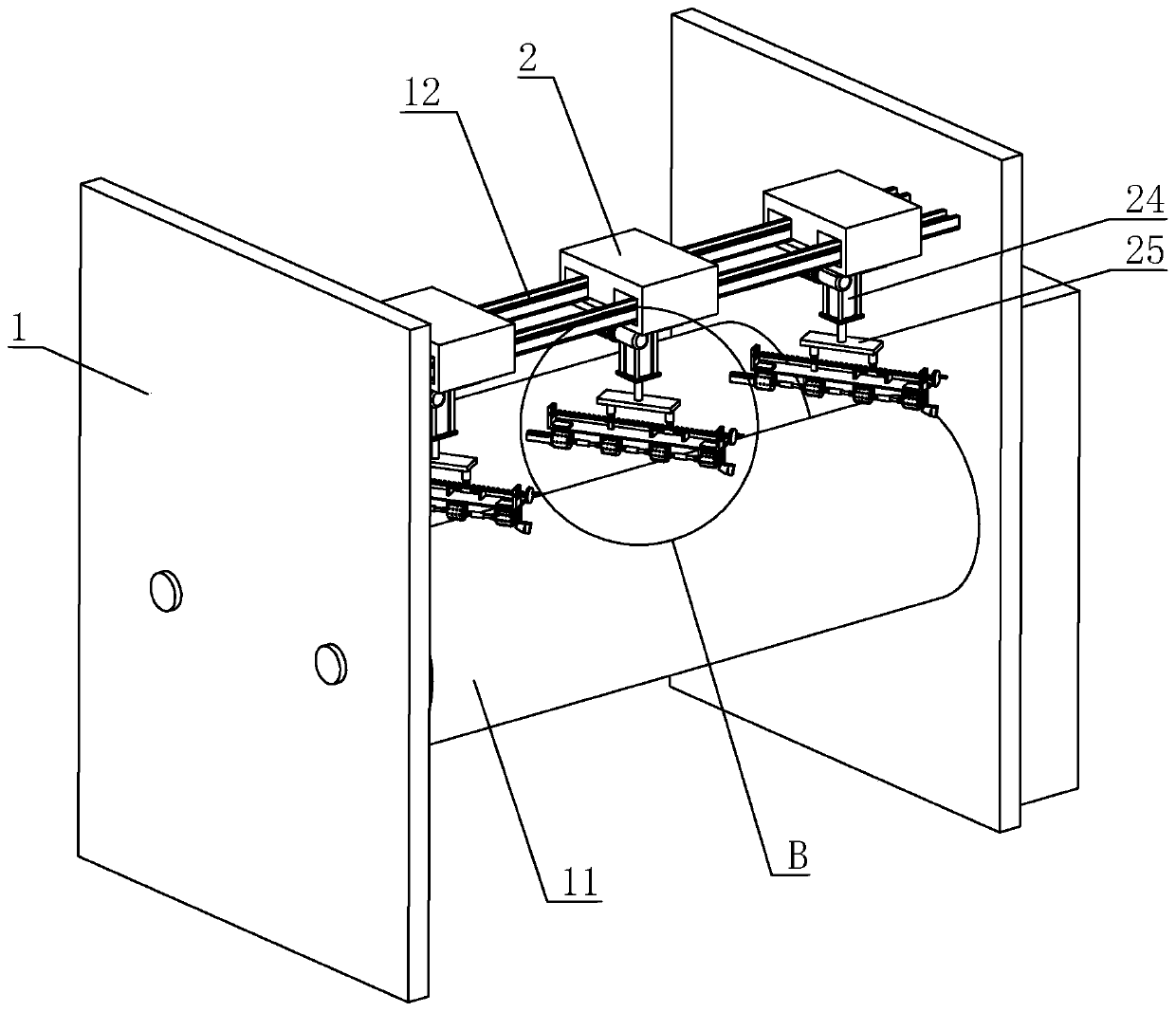

[0040] An open mill, refer to figure 1 , Including a frame 1, two squeeze rollers 11 driven by hydraulic motors are arranged at intervals on the frame 1, and a guide rail 12 is fixed on the frame 1 and located above the squeeze roller 11. The length direction of the guide rail 12 is The axial direction of the pressing roller 11 is parallel.

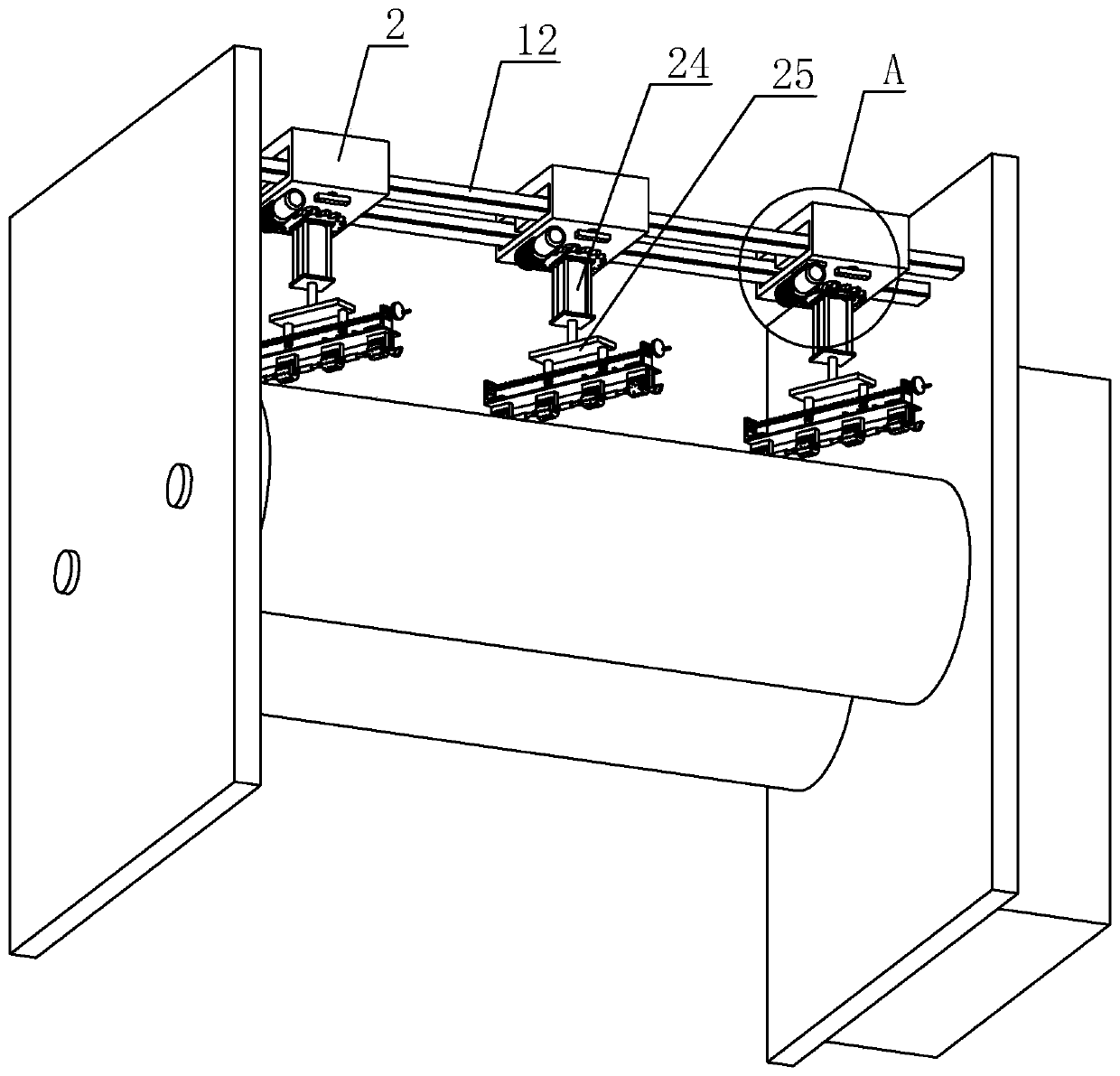

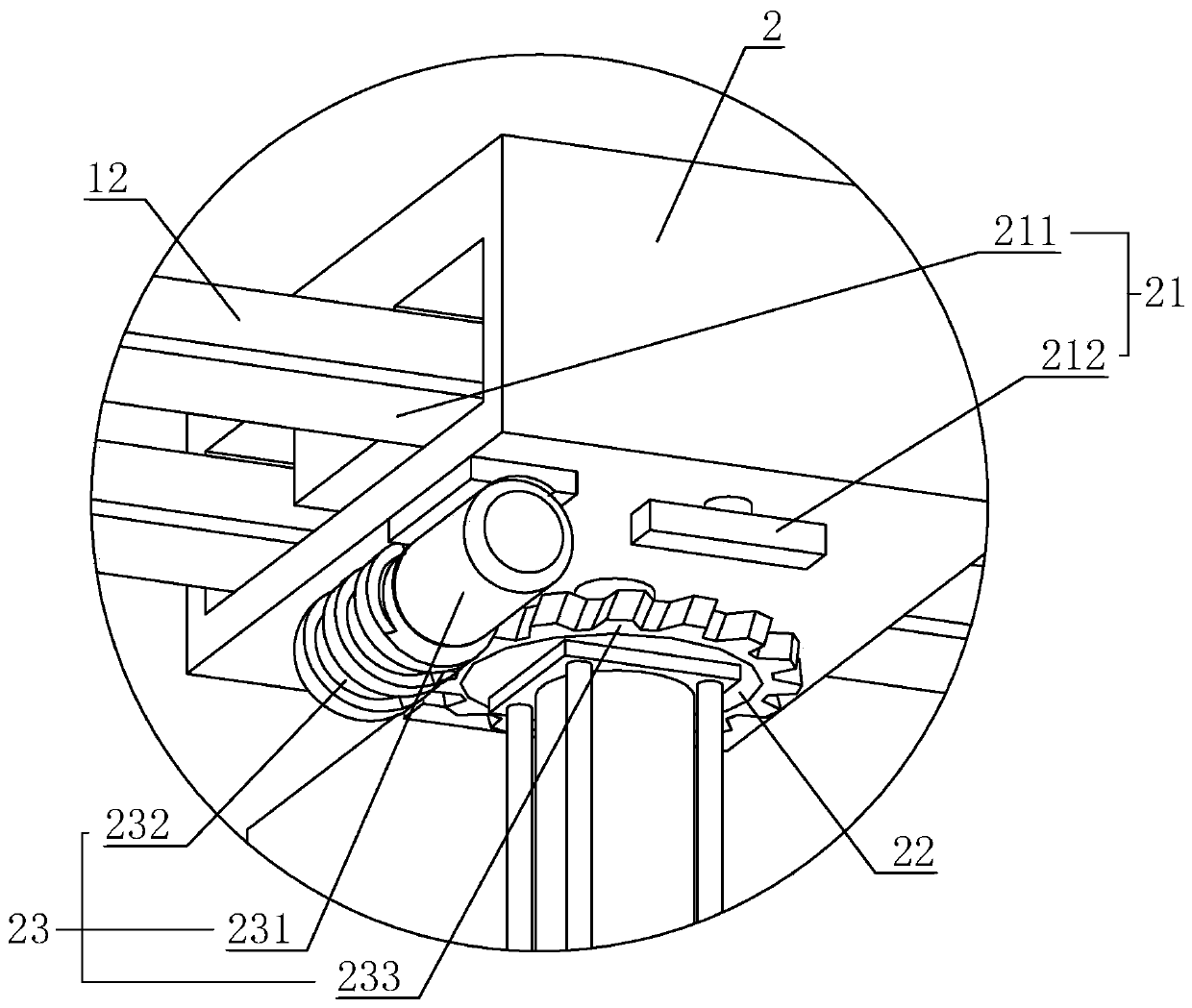

[0041] Reference figure 2 with image 3 , A plurality of mounting frames 2 are provided on the guide rail 12 by sliding wheels, and the mounting frame 2 is provided with a fixing assembly 21 connected with the guide rail 12. The fixing assembly 21 includes a rubber band 211 and a T-shaped rod 212. The rubber band 211 is fixedly arranged on the lower surface of the guide rail 12. The T-shaped rod 212 is threadedly installed on the lower surface of the mounting frame 2, and the T-shaped rod 212 passes through the mounting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com