Flat plate solar energy heat absorption coating

A technology of flat-panel solar energy and heat-absorbing coatings, applied in radiation-absorbing coatings, coatings, etc., can solve the problems of complex process, high cost, and high requirements, and achieve the goals of improving waterproof performance, reducing preparation costs, and improving heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

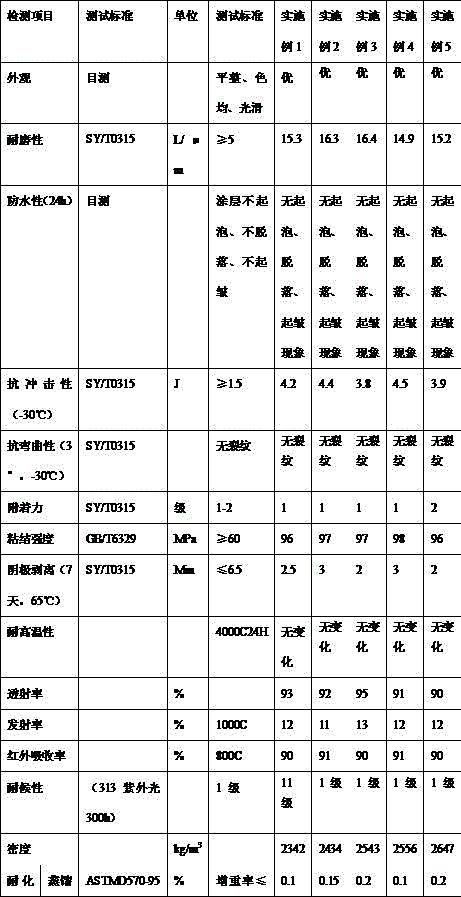

Examples

Embodiment 1

[0031] A kind of flat solar heat absorbing paint, raw material is:

[0032] Film-forming agent: modified casein-gelatin 50kg;

[0033] Film-forming aids: ethylene glycol monobutyl ether 2kg, triethylene glycol monomethyl ether 8kg;

[0034] Light absorbing agent: mix 8kg of cobalt blue powder, 12kg of cobalt manganese copper oxide, and 15kg of enamel black into black;

[0035] Solvent: acetic acid 6kg, anhydrous butyl acetate 8kg, glycerol 6kg;

[0036] Auxiliaries are plasticizers, coupling agents, leveling agents, wetting agents and defoamers, wherein,

[0037] Plasticizer: dibutyl phthalate 2kg;

[0038] Coupling agent: silane coupling agent 1kg, titanate coupling agent 2kg;

[0039] Leveling agent: EFKA35702kg, EFKA35801kg for uniform mixing;

[0040] Wetting agent: polysiloxane 2kg;

[0041] Defoamer: polyoxyethylene oxypropylene glycerin 1kg.

[0042] The steps of preparing flat solar heat absorbing coatings according to the above-mentioned raw materials are as foll...

Embodiment 2

[0046] A kind of flat solar heat absorbing paint, raw material is:

[0047] Film-forming agent: modified casein-gelatin 100kg;

[0048] Film-forming aids: ethylene glycol monobutyl ether 15kg, triethylene glycol monomethyl ether 8kg, dodecyl alcohol ester 7kg;

[0049] Light absorbing agent: use 10kg of cobalt blue powder, 20kg of cobalt manganese copper oxide and 25kg of enamel black;

[0050] Solvent: 15kg of glycerol, 15kg of tetrahydrofuran-oxypropylene copolymerized glycol and 25kg of polyurethane polyether polyol;

[0051] Auxiliaries are plasticizers, coupling agents, leveling agents, wetting agents and defoamers, wherein,

[0052] Plasticizer: dibutyl phthalate 3kg;

[0053] Coupling agent: aluminate coupling agent 2kg;

[0054] Leveling agent: YCK-13605kg;

[0055] Wetting agent: polyether modified polydimethylpolysiloxane 2kg;

[0056] Defoamer: polyoxyethylene polyoxypropylene pentaerythritol ether 3kg;

[0057] The steps of preparing flat solar heat absorbin...

Embodiment 3

[0061] A kind of flat solar heat absorbing paint, raw material is:

[0062] Film-forming agent: modified casein-gelatin 80kg;

[0063] Film-forming aids: triethylene glycol monomethyl ether 9kg, dodecyl alcohol ester 10kg, propylene glycol monobutyl ether 11kg;

[0064] Light absorbing agent: Use 18kg of chromium oxide green powder, 12kg of selenium cadmium sulfide powder, and 20kg of iron oxide red powder to make red;

[0065] Solvent: acetic acid 20kg, and polyurethane polyether polyol 20kg;

[0066] Auxiliaries are plasticizers, coupling agents, leveling agents, wetting agents and defoamers, wherein,

[0067] Plasticizer: dibutyl phthalate 2kg;

[0068] Coupling agent: a mixture of 2 kg of phosphate coupling agent and 2 kg of borate coupling agent;

[0069] Leveling agent: mix BYK-3332kg and TEGOGlide1002kg;

[0070] Wetting agent: polyester modified polydimethylsiloxane 3kg;

[0071] Defoamer: Polyoxypropylene 2kg.

[0072] The steps of preparing flat solar heat abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com