All-level boiler heating surface flue-gas temperature determination method and device

A technology of flue gas temperature and heating surface, applied in the field of boilers, can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0083] The inventor found that the temperature and pressure of the working medium at the inlet and outlet of the heating surface of the boiler at all levels are already on the DCS dial. The gas temperature will be more accurate than the flue gas temperature of the heating surface of the boiler at all levels assumed in the prior art. Based on this, an embodiment of the present invention provides a method for determining flue gas temperatures on heating surfaces of boilers at various stages.

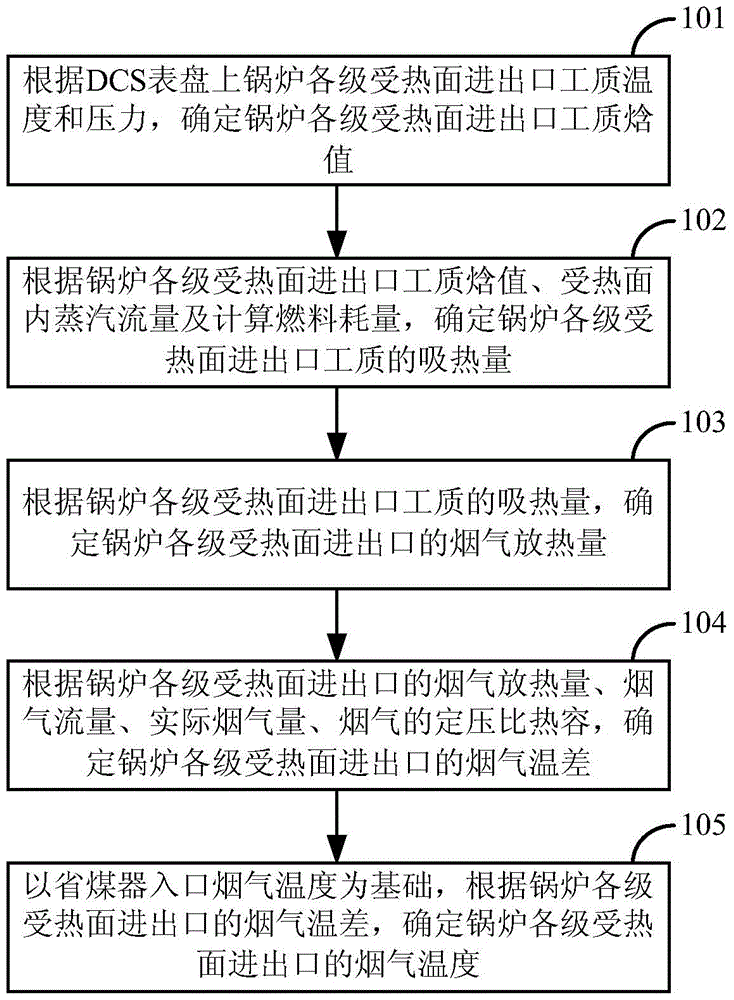

[0084] figure 1 It is a schematic diagram of the method for determining the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com