A Simulated Hoisting Equipment Applicable to Multiple Size Pipe Strings

A multi-size, string technology, applied in the testing of mechanical equipment, mechanical parts, machine/structural parts, etc., to reduce the difficulty of operation and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

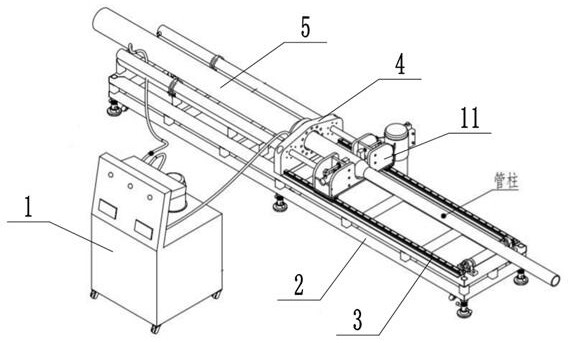

[0029] refer to figure 1 As shown, a simulated tripping equipment applicable to multi-size pipe strings includes a conveying device and a control device 1 . The conveying device includes a conveying base, a clamping mechanism and an actuating oil cylinder 18 .

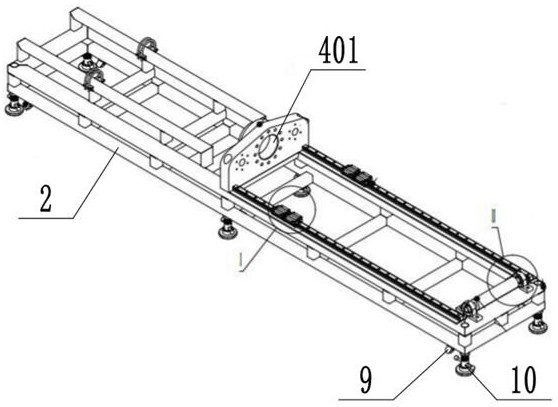

[0030] refer to Figure 2-4 As shown, the conveying base includes a conveying frame 2, a long guide rail 3, an auxiliary roller, a fixing plate 4 and a simulated pipe column 5. The fixing plate 4 is vertically fixed and installed in the middle of the conveying frame 2, and the simulated pipe column 5 is fixedly installed in the middle of the fixing plate 4. On the rear end surface, and the fixed plate 4 is provided with a through hole 401 that communicates with the simulated pipe string 5; the inner diameter of the through hole 401 is greater than or equal to the inner diameter of the simulated pipe string 5, and a plurality of long guide rails 3 are fixed side by side and installed on the front side of the fixed plate...

Embodiment 2

[0043] As a preferred embodiment of the present invention, on the basis of the first embodiment, a moving component and a fixed component are added to the bottom of the conveying frame 2 in this embodiment, specifically:

[0044] refer to figure 2 As shown, in this embodiment, a plurality of pulleys 9 and an adjustment base 10 are evenly distributed at the bottom of the transmission frame 2 , and the height of the adjustment base 10 is adjustable.

[0045] The transmission base is provided with a pulley 9, and the transmission base is placed in the test area through the pulley 9; the adjustment base 10 is raised to fix the transmission base to the corresponding test area.

Embodiment 3

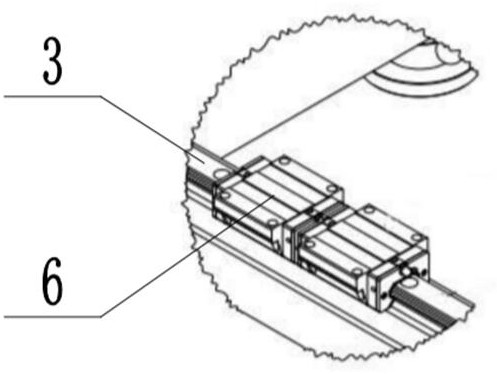

[0047] As a preferred embodiment of the present invention, this embodiment optimizes the setting of the long guide rail 3 on the basis of the second embodiment, specifically:

[0048] In this embodiment, two long guide rails 3 are provided, and two slide rail seats 6 are slidably installed on each long guide rail 3; It is beneficial to improve the stability of the operation of the clamping mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com