Graphene/phase-change microcapsule composite material and preparation method and application thereof

A technology of phase-change microcapsules and graphene-based materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as leakage of phase-change materials, improve heat absorption performance, improve heat absorption efficiency, and improve material performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

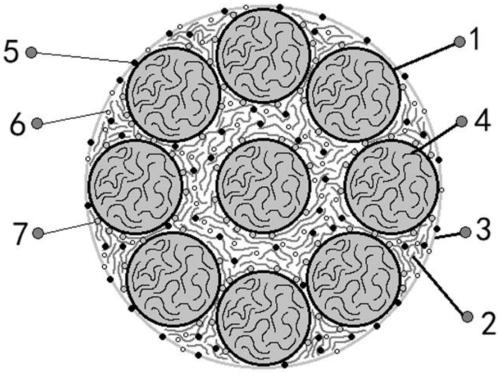

[0058] Such as figure 1 Shown, a kind of graphene / phase change microcapsule composite material, it comprises:

[0059] A plurality of phase change microcapsules 1;

[0060] A heat conduction network 2, the heat conduction network 2 is wrapped outside each phase change microcapsule 1 and combines each phase change microcapsule 1 with each other;

[0061] And, a shell structure 3 wrapped outside the phase change microcapsule 1 and the heat conduction network 2;

[0062] Wherein: the heat conduction network 2 and the shell structure 3 are made of graphene materials.

[0063] In the above-mentioned graphene / phase change microcapsule composite material, the graphene material wraps the phase change microcapsule 1, relying on the graphene material on the surface of the phase change microcapsule 1 and the graphene sandwiched between the phase change microcapsules after drying. The heat conduction network 2 between the phase change microcapsules is formed by similar materials, and ...

Embodiment 2

[0075] A preparation method of graphene / phase-change microcapsule composite material, comprising the following steps:

[0076] Disperse the 5wt% graphene slurry in deionized water, disperse for 8h at a speed of 2000rpm, and obtain a graphene dispersion with a concentration of 2wt%;

[0077] Mix 10g of phase-change microcapsules with 100g of graphene dispersion liquid with a concentration of 2wt%, stir and disperse, and dry at 60-90°C to obtain a graphene / phase-change microcapsule composite material.

Embodiment 3

[0079] A preparation method of graphene / phase-change microcapsule composite material, comprising the following steps:

[0080] Use 1g of silane coupling agent to modify the surface of 10g of phase change microcapsules, the modification steps are as follows:

[0081] 1) Weigh 180g of absolute ethanol, 20g of deionized water, and mix with each other; 2) Add acetic acid (with 36%wt concentration of acetic acid), adjust the pH to about 4; 3) Add 20g of KH-570 silane coupling agent dropwise Stir magnetically for 2 hours; 4) Stand still for at least 4 hours until the silane coupling agent is fully hydrolyzed; 5) Weigh 11g of the above liquid and mix it with 10g of microcapsules, add an appropriate amount of deionized water to dilute, stir at 600rpm for 2 hours, and put it into blast drying Take out the box after it is completely dry at 60°C.

[0082] Disperse the 5wt% graphene slurry in deionized water, disperse for 8h at a speed of 2000rpm, and obtain a graphene dispersion with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com