Roots pump with rotor cooling structure

A technology of rotor cooling and Roots pump, which is applied to rotary piston type/swing piston type pump components, components of pumping devices for elastic fluid, pump components, etc. Poor cooling effect and other problems, to achieve the effect of improving service life, speeding up flow rate and facilitating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

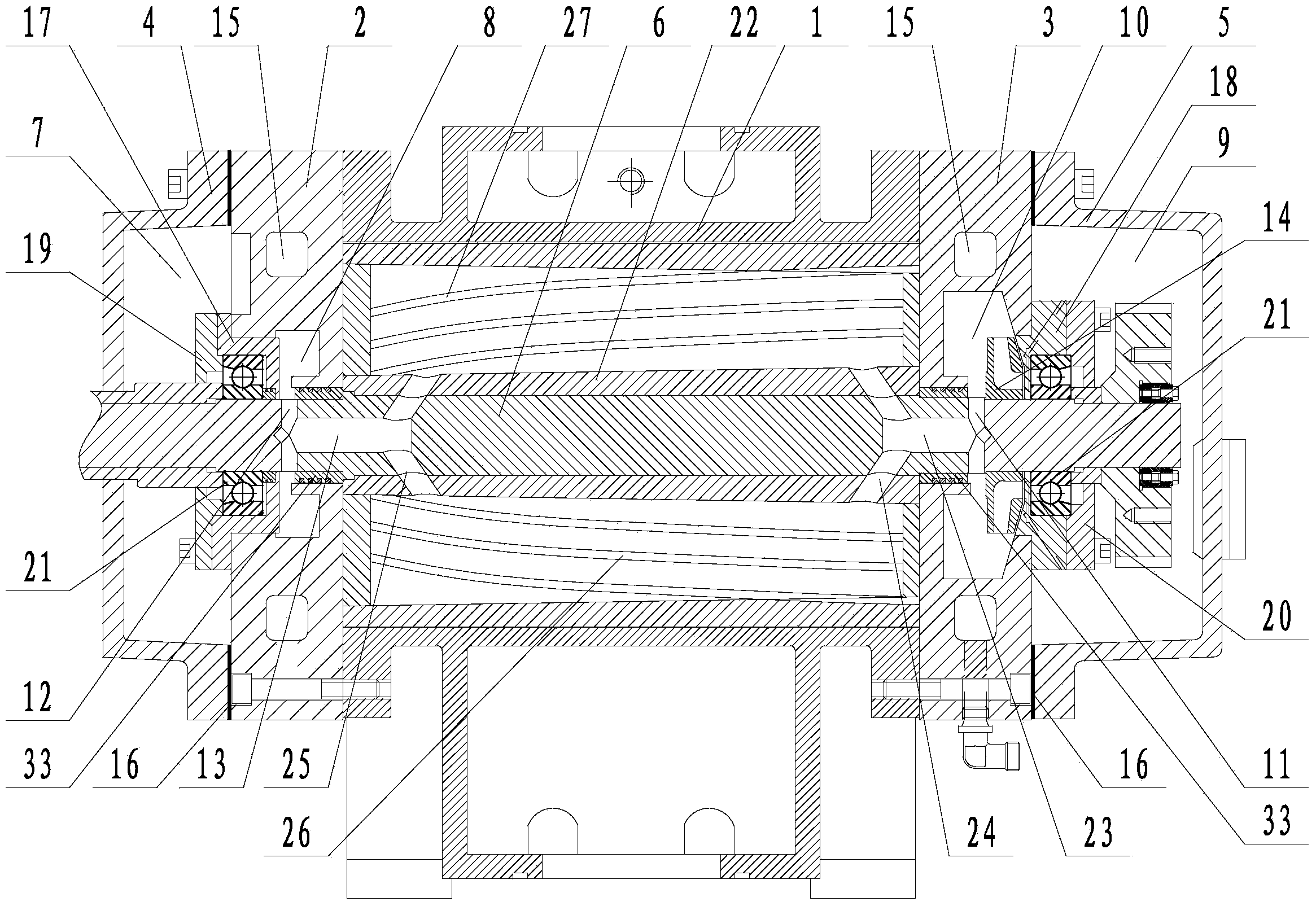

[0026] Embodiment 1: A Roots pump with rotor cooling structure (see attached figure 1 ), including the pump body 1, the front and rear ends of the pump body are respectively connected with the front side cover 2 and the rear side cover 3, the front side cover is connected with the front cover 4, the rear side cover is connected with the rear cover 5, the front cover and the front side cover The connecting position of the connecting position and the connecting position of the back cover and the rear side cover are all provided with a sealing gasket 16, a rotating shaft 6 is connected between the front cover and the back cover, and a rotor 22 is connected on the rotating shaft, and the rotor is arranged in the pump body. The front cover is provided with a front cover cavity 7, the front side cover is provided with a front cooling cavity 8, the rear cover is provided with a rear cover cavity 9, and the rear side cover is provided with a rear cooling cavity 10. A front bearing sea...

Embodiment 2

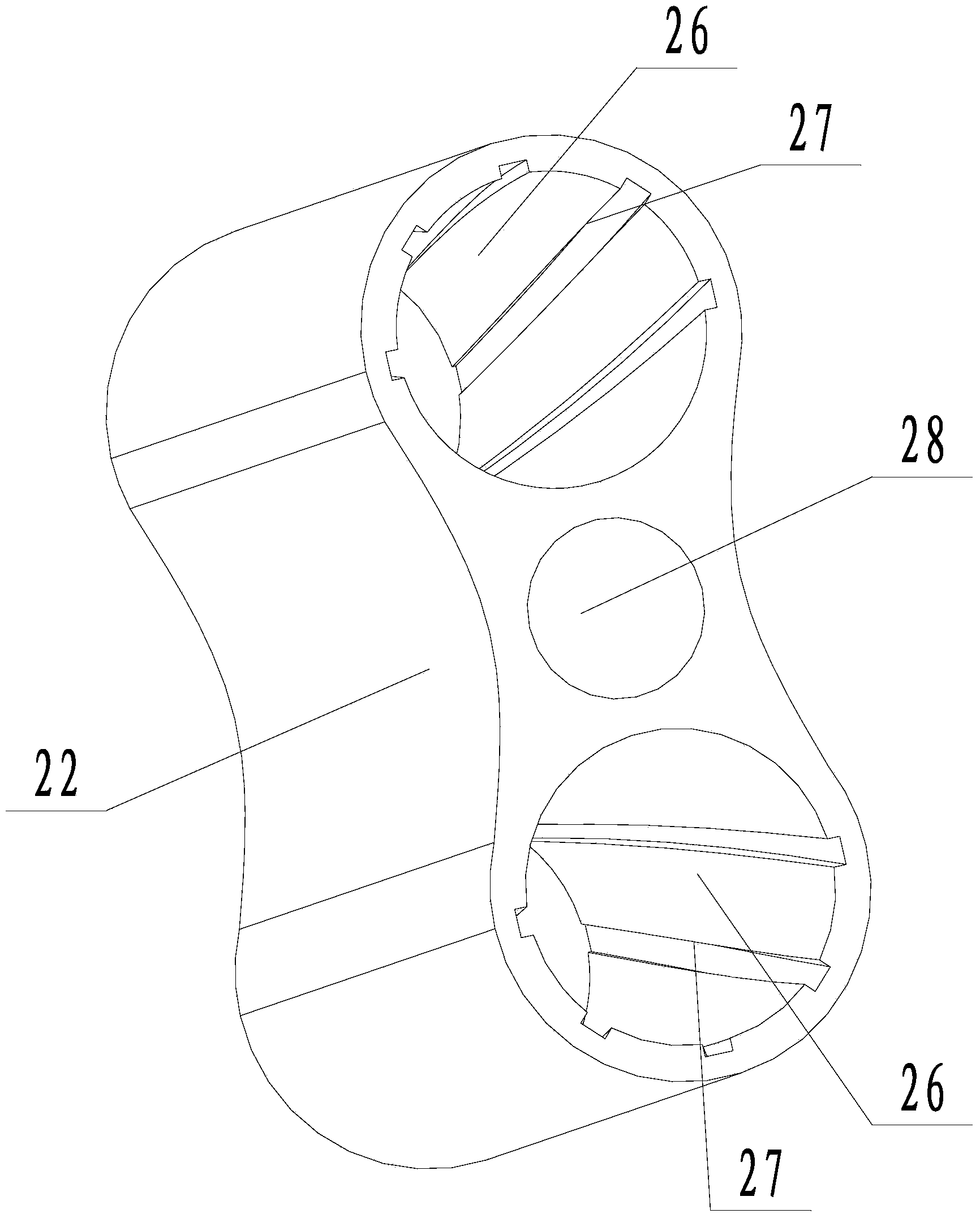

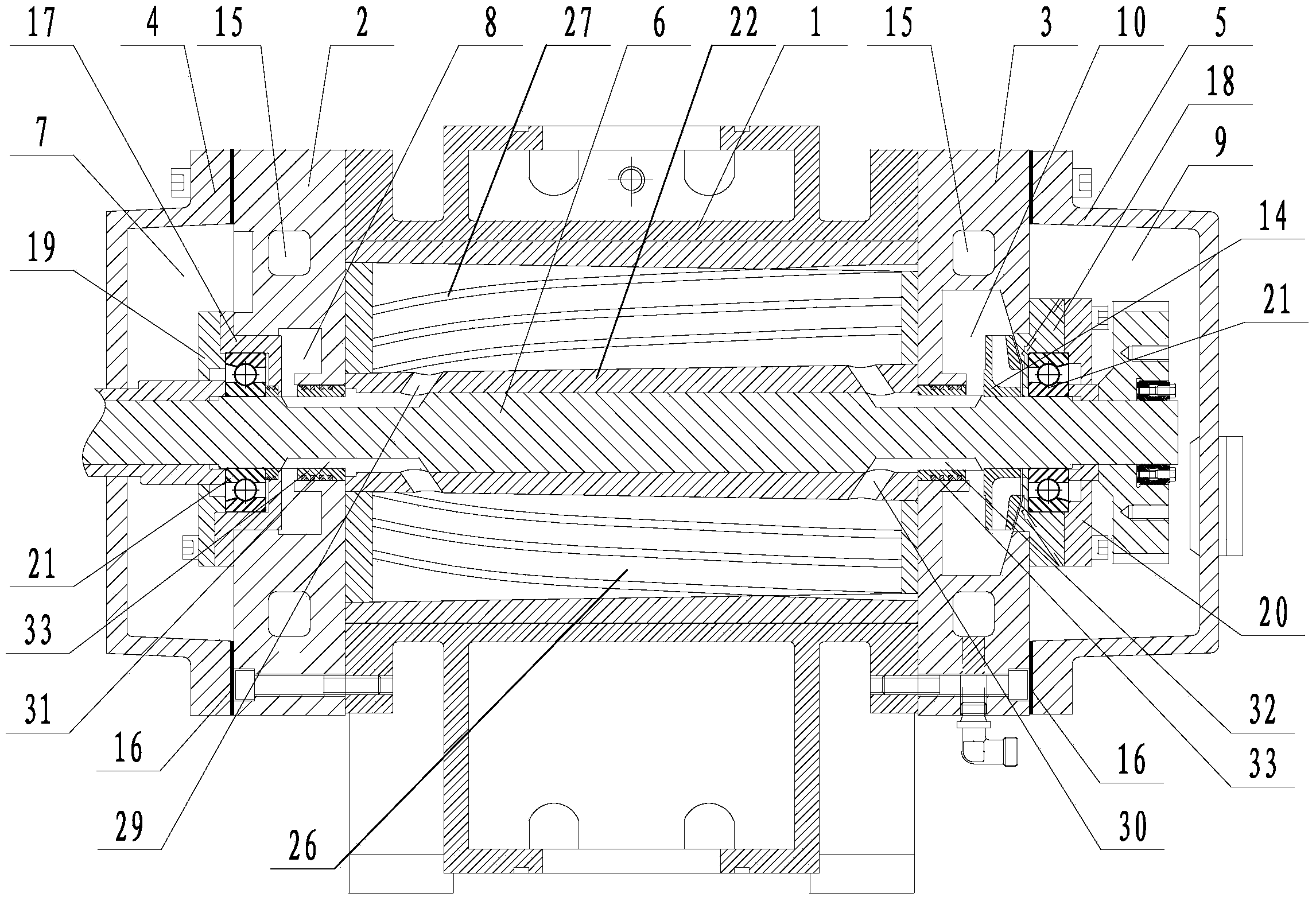

[0028] Embodiment 2: A Roots pump with rotor cooling structure (see attached image 3 ), its structure is similar to that of Embodiment 1, the main difference is that there is a connecting hole 28 in the middle of the rotor, the rotating shaft is fitted and connected in the connecting hole, and the inner walls of the connecting hole near the openings at both ends are respectively provided with two front connecting holes The hole 29 and the two rear communication holes 30, one front communication hole and one rear communication hole communicate with one rotor cooling chamber, and the other front communication hole and the other rear communication hole communicate with another rotor cooling chamber. Two front communication grooves 31 and two rear communication grooves 32 are respectively provided on the outer wall of the rotating shaft near the two ends of the rotor. Two back holes. The cooling water passes through the rear communication groove and the rear communication hole f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com