Light pipe evaporators and refrigerator

A technology of evaporators and light pipes, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of lower evaporation temperature, lower heat absorption capacity, inconsistent temperature between the upper and lower freezers, etc., and achieve a balanced heat absorption capacity , improve utilization efficiency, and improve the effect of cooling speed experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

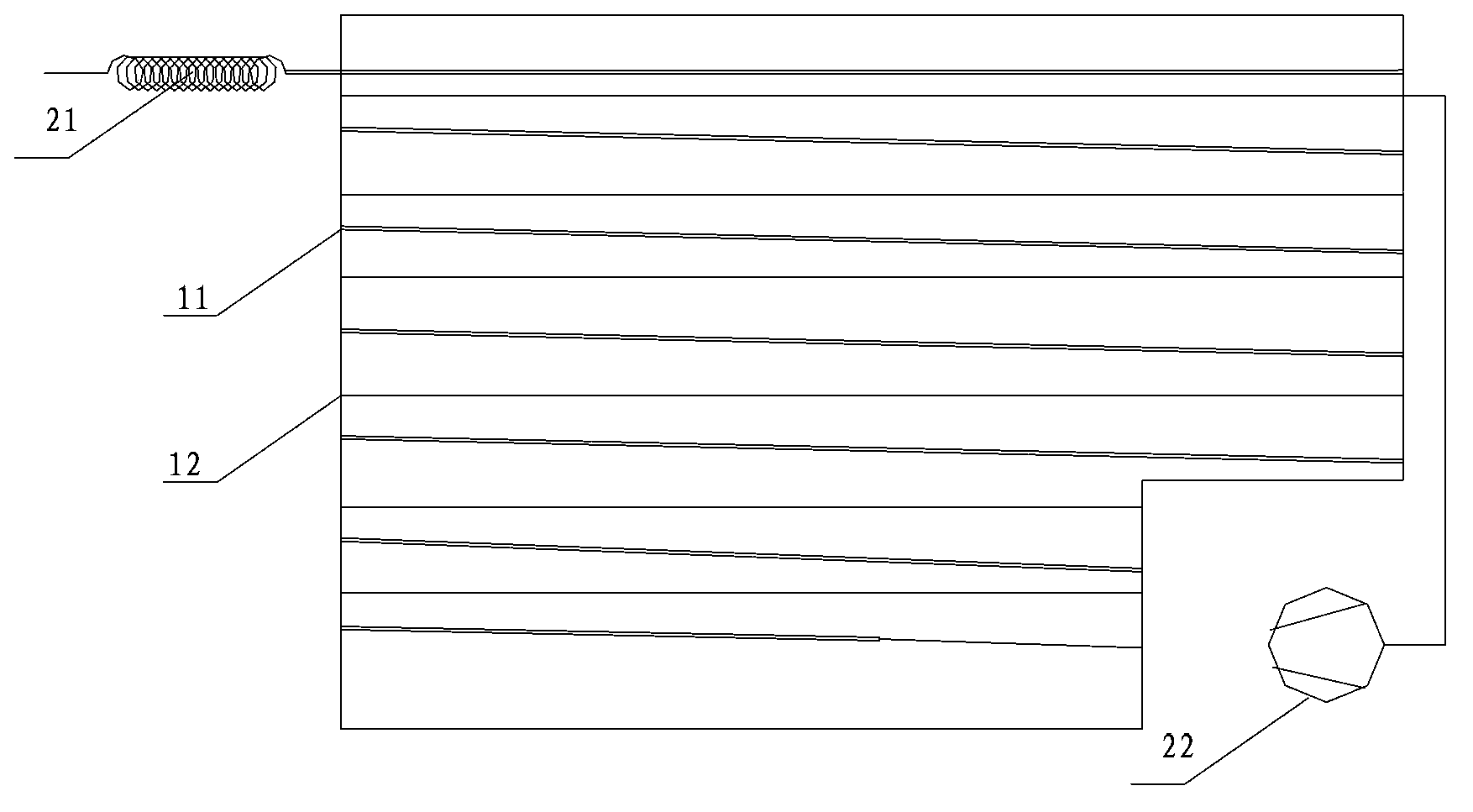

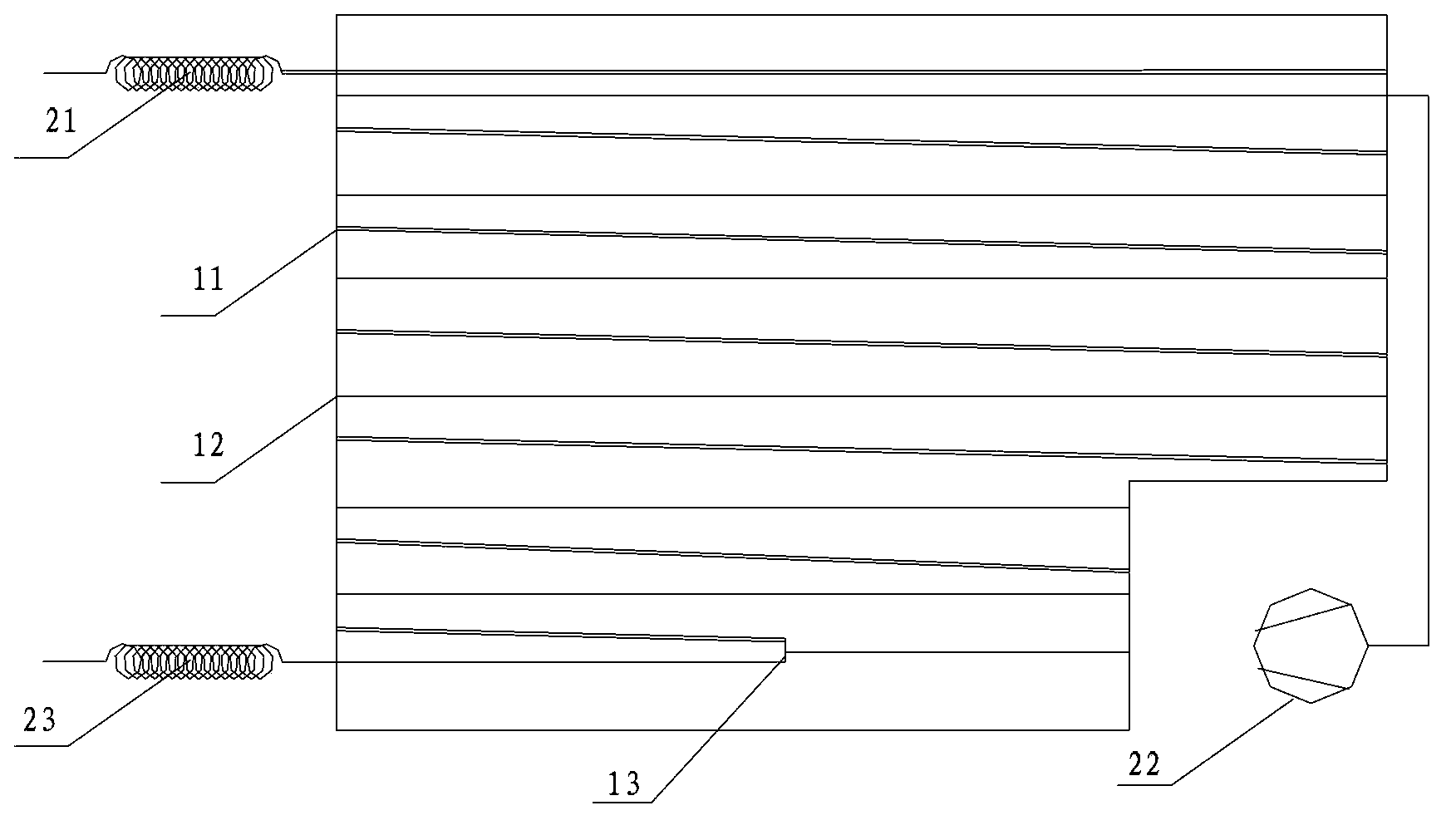

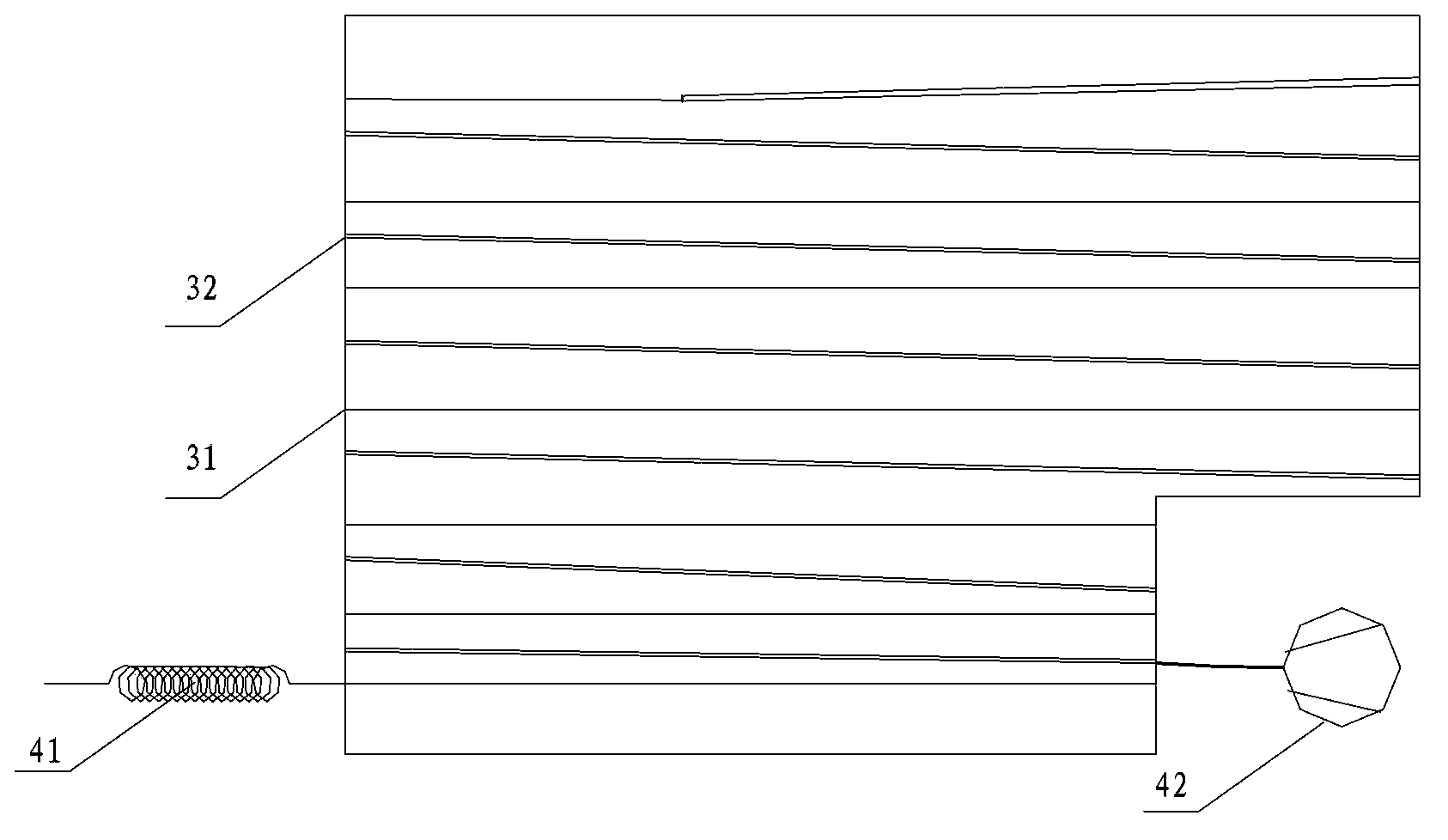

[0018] Aiming at the defects of the prior art, the embodiment of the present invention provides a light tube evaporator, figure 1 It is a schematic diagram of the structure of the light tube evaporator in the embodiment of the present invention Figure 1 ,like figure 1 As shown, the light tube evaporator is formed by winding the evaporating tube around the inner tank of the refrigeration equipment. The evaporating tube of the light tube evaporator includes a first part of evaporating tube 11 and a second part of evaporating tube 12, and the first part of evaporating tube 11 is along the The inner tank wall of the refrigeration equipment is wound from top to bottom, and the first part of the evaporation tube 11 is located on the upper part of the inner tank wall of the refrigeration equipment, and is provided with a first interface for connecting the first capillary tube 21; the second part The evaporation pipe 12 is wound from bottom to top along the inner tank wall of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com