Loop heat pipe solar system with fins of different heights in heat collection pipes

A technology of loop heat pipes and heat collecting pipes, which is applied in the field of solar energy, can solve the problems of reducing the life of heat collecting pipes, uneven heating, focus shift, etc., and achieve the effects of avoiding heat loss, increasing absorption strength, and improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

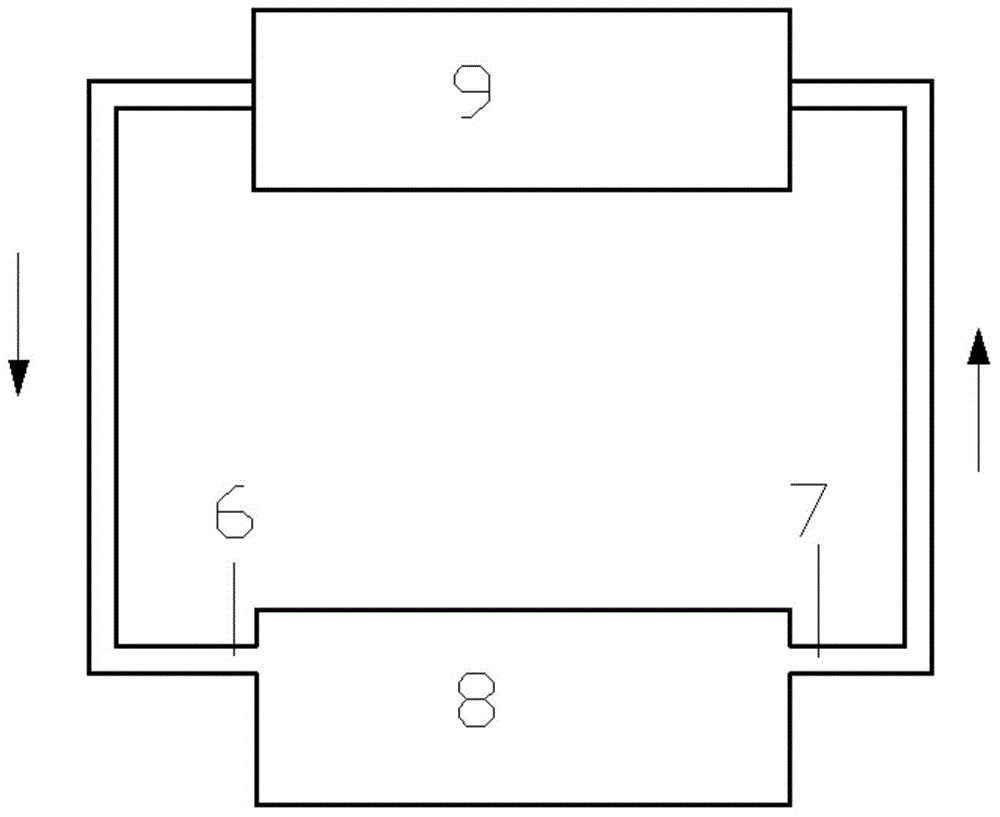

[0033] A loop heat pipe solar collector system such as figure 1 Shown, comprise solar heat collector 8 and water tank 9 and loop heat pipe, wherein the evaporation section of loop heat pipe is in heat collector 8, and the condensation section of loop heat pipe is arranged in water tank 9; Heat collector 8 absorbs solar energy Heat, after the water in the collector evaporates, it enters the condensation section of the loop heat pipe. The condensation section releases heat to heat the water in the water tank. After the heat release in the condensation section is completed, it circulates into the heat collector for heating.

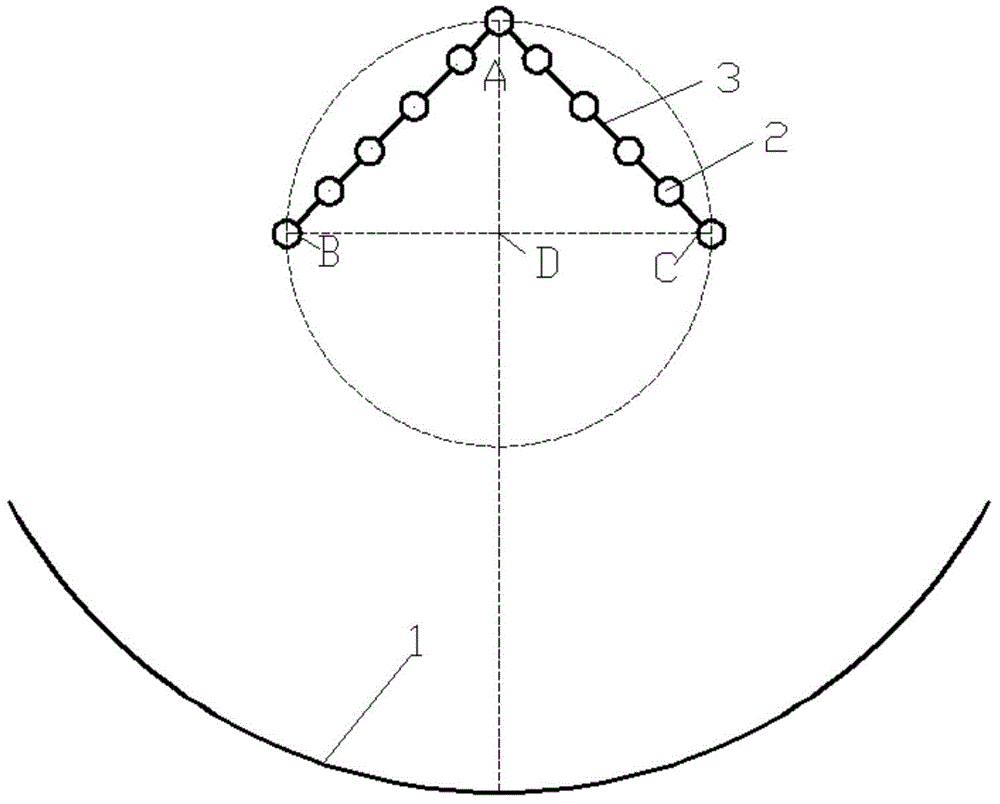

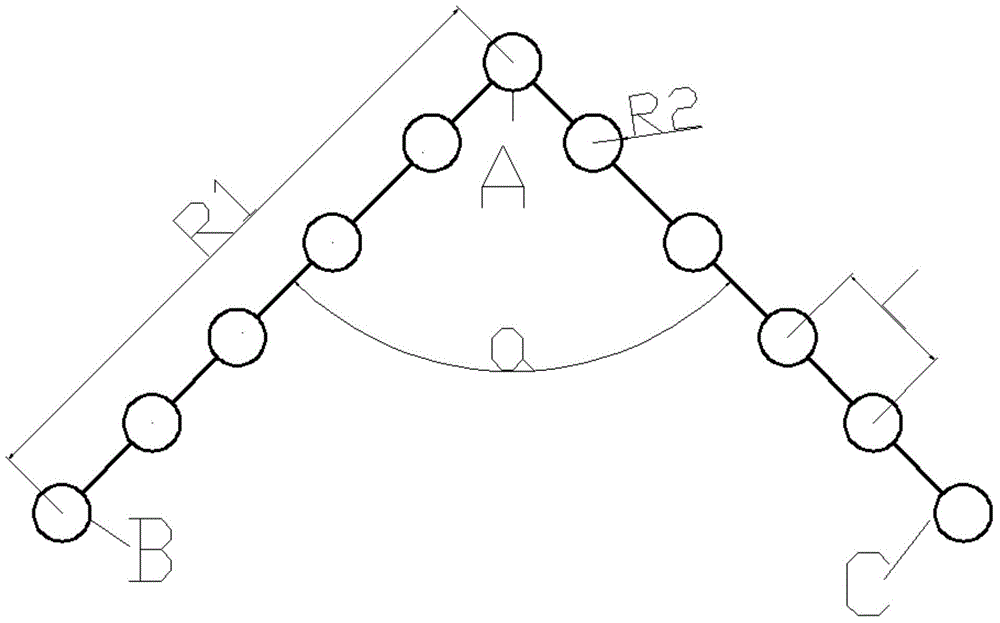

[0034] figure 2 The specific structure of the heat collector 8 is shown, such as figure 2 As shown, the heat collector includes a heat collecting tube 2, a reflector 1 and a heat collecting plate 3, and two adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com