Flat plate heat collector with vein-shaped runners

A flat-plate collector and leaf vein technology, which is applied to solar collectors, solar collectors, heating devices, etc. using working fluid, can solve the problem of uneven heating of the heat-absorbing medium and the fact that the instantaneous efficiency of the flat-plate collector is difficult to reach the national level. Standard requirements and other issues to achieve the effect of improving the heat absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

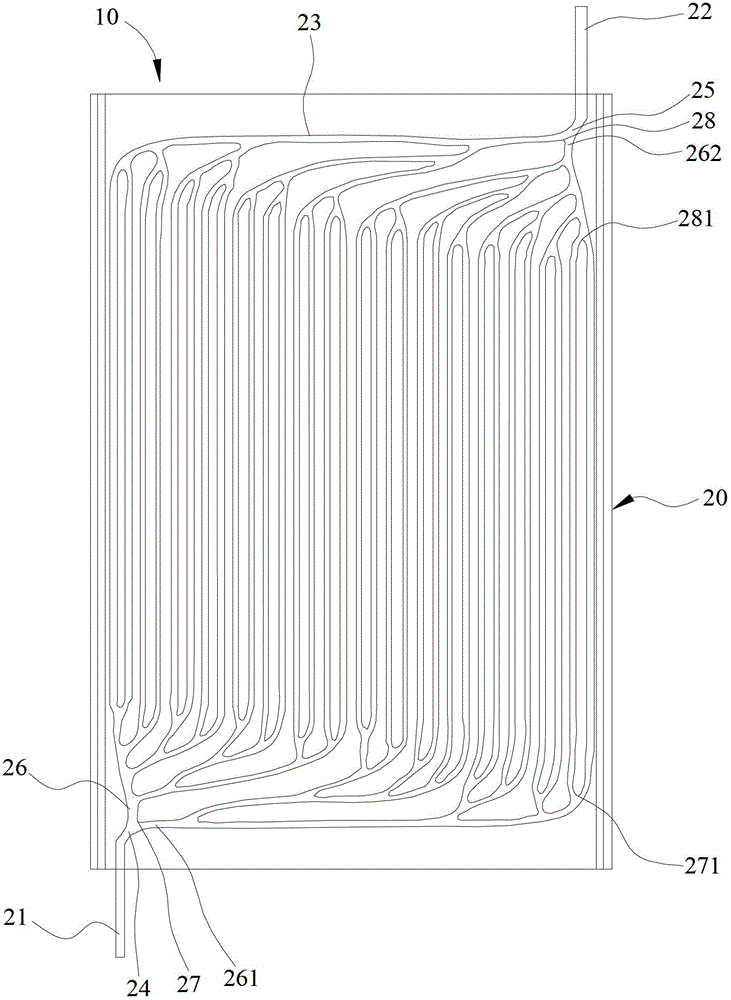

[0025] see figure 1 As shown, the present invention provides a flat plate heat collector 10 with a vein-shaped flow channel, including a heat absorber 20, an absorbing coating, a heat insulation layer, a cover plate and a frame, wherein the frame is used for fixing and installing the heat absorber 20 , heat insulation layer, cover plate; the heat insulation layer is arranged under the heat absorber 20, in order to prevent the heat absorber 20 from dissipating heat to the surrounding environment through conduction; the cover plate is arranged on the top of the heat absorber 20; in addition, the absorbing coating Coated on the heat absorber 20 to absorb solar radiation energy to the greatest extent and convert it into heat energy. The heat absorber 20 includes a first header 21, a second header 22 and a branch pipe 23, the second header 22 is spaced apart from the first header 21; the branch pipe 23 is connected to the first header 21 and the second header 22 Between them, the ...

Embodiment 2

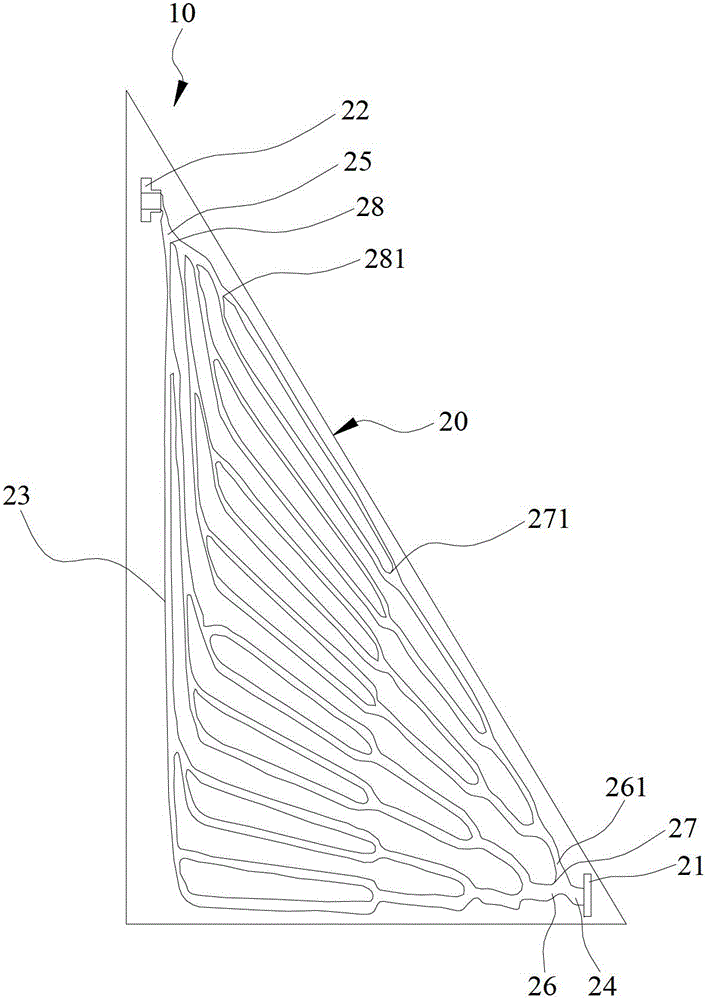

[0038] see figure 2 As shown, the difference between the second embodiment and the first embodiment is that the heat absorbing plate 20a of the first embodiment has a rectangular structure, while the heat absorbing plate 20a of the second embodiment has a triangular structure. Among them, the rectangular structure is not only easy to manufacture and saves materials, but also in the case of the same material, the rectangular structure is larger than the general geometric area, for example, its area is larger than the circular structure, so its corresponding absorption area will also larger. However, the triangular structure of this embodiment has the characteristics of better stability and is suitable for installation in narrow places. In general, whether the heat absorbing plate 20a is made into a rectangular structure or a triangular structure is mainly determined based on the actual needs of users and the installation environment, but the structure of the heat absorbing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com