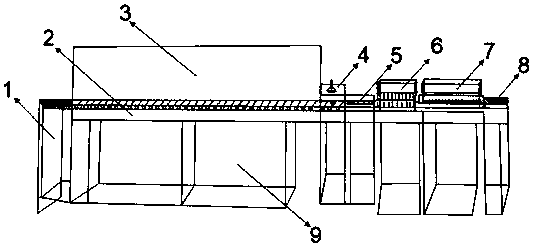

Horizontal roller way type dinner plate toughening furnace and production technology thereof

A production process and horizontal roller technology, which is applied to the horizontal roller table plate tempering furnace and its production process, can solve the problems of uneven heating, single function and low quality of glass, and achieve good resistance to sudden temperature changes and stable operation. , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a preparation process of a horizontal roller table tempering furnace for dinner plates.

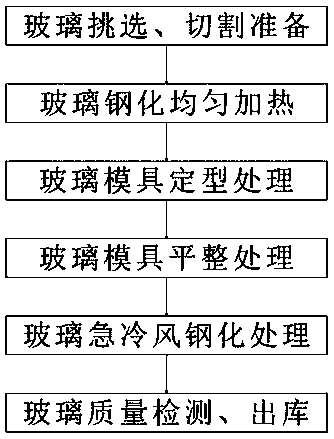

[0033] A preparation process for tempered glass, comprising the following steps:

[0034] Step 1: After screening the glass, select the glass with a thickness of 1-3mm, cut, edge, open holes, wash and dry in sequence, and place it on the loading table;

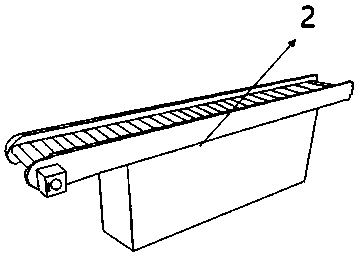

[0035] Step 2: The glass on the loading table is transferred to the heating furnace body through the conveying device. The roller table movement of the glass in the furnace uses unbounded dynamic rate and temperature control to reduce the step change of the temperature field, so that the absorption of different areas of the same piece of glass The heat is more uniform. Since the thickness of the glass is 1-3mm, a fourth-order temperature gradient is selected. The glass enters the heating furnace body 2, moves on the conveying roller table 33 through the glass, and passes through the electric heating on the el...

Embodiment 2

[0041] The invention provides a preparation process of a horizontal roller table tempering furnace for dinner plates.

[0042] A preparation process for tempered glass, comprising the following steps:

[0043] Step 1: After the glass is screened, the glass with a thickness of 3-5mm is selected, cut, edged, opened, and cleaned and dried in sequence. While opening the hole, it needs to be continuously rinsed with clean water and placed on the loading table;

[0044] Step 2: The glass on the loading table is transferred to the heating furnace body through the conveying device. The roller table movement of the glass in the furnace uses unbounded dynamic rate and temperature control to reduce the step change of the temperature field, so that the absorption of different areas of the same piece of glass The heat is more uniform. Since the thickness of the glass is 3-5mm, a six-step temperature gradient is selected. The glass enters the heating furnace body 2, moves on the conveying r...

Embodiment 3

[0050] The invention provides a preparation process of a horizontal roller table tempering furnace for dinner plates.

[0051] A preparation process for tempered glass, comprising the following steps:

[0052] Step 1: After selecting the glass with a thickness of 5-8mm, cut the larger original piece with diamond according to the size of the required product, and then use the grinding head double round edge machine to smooth the edge of the glass, and open the glass After processing, the hole size is set according to the specific requirements, and finally cleaned and dried, then placed on the loading table;

[0053] Step 2: The glass on the loading table is transferred to the heating furnace through the conveying device. The temperature zone is set in the furnace, and the glass moves on the roller table in the furnace. The step change of the temperature field is reduced by unbounded motion rate and temperature control, so that the same The heat absorption in different regions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com