High-alkalinity high-concentration printing and dyeing wastewater anaerobic pretreatment system and process

A technology for high-concentration wastewater, printing and dyeing wastewater, applied in anaerobic digestion treatment, textile industry wastewater treatment, water treatment parameter control, etc. Reduce the life of processing equipment and other problems, to achieve the effect of reducing alkali callback costs, small safety risks, and satisfying COD values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

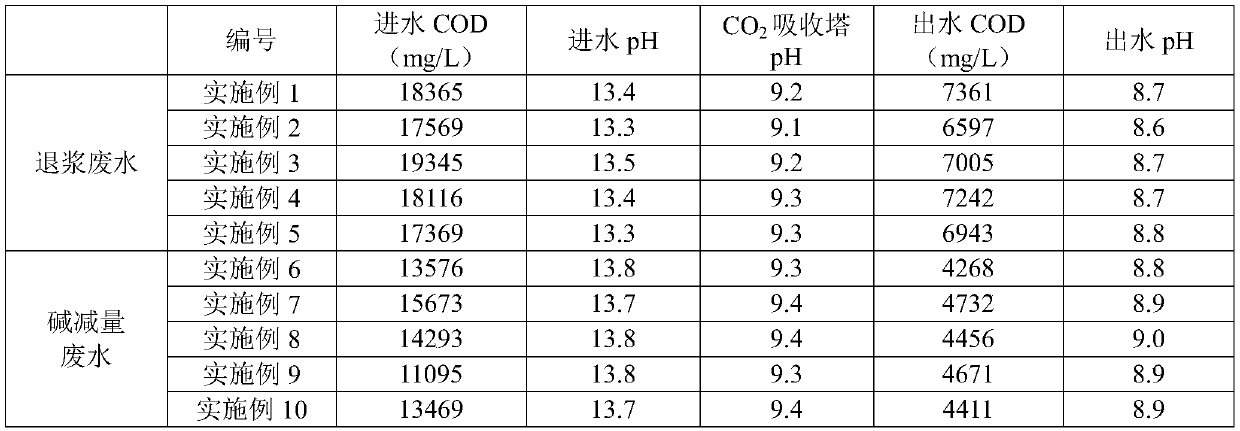

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0037] The accompanying drawings in the present invention are only the structure and connection schematic diagrams of each device, and do not represent the actual placement and pipeline laying. Instruments and devices used in the present invention are conventional instruments and devices in the prior art without specific instructions, and are not the focus of the present invention.

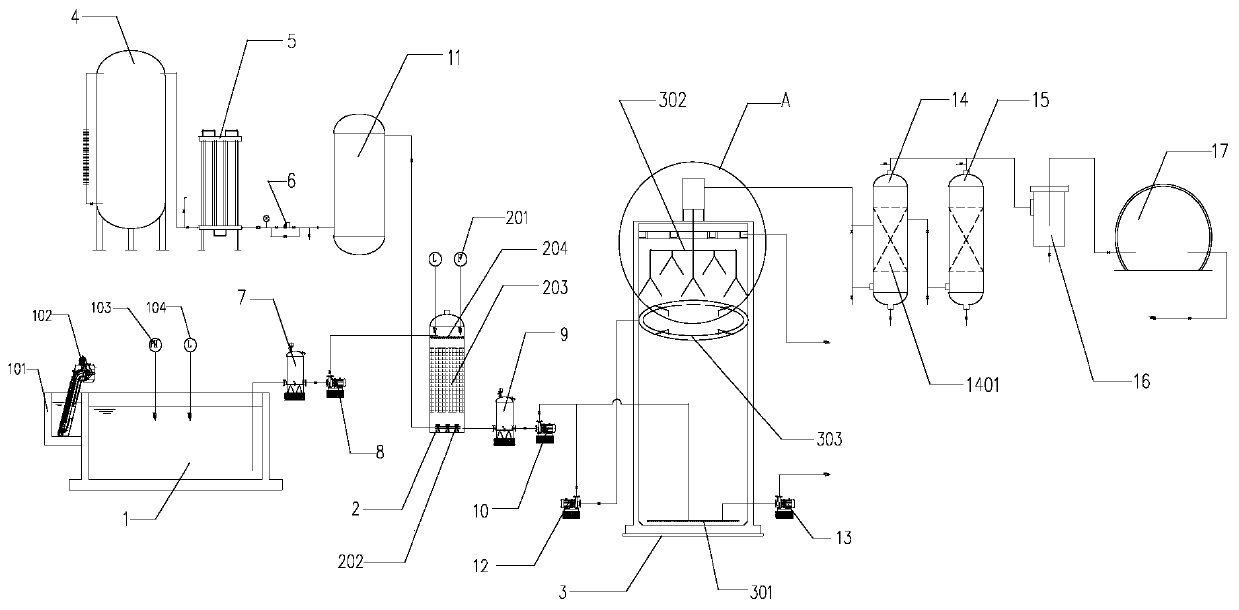

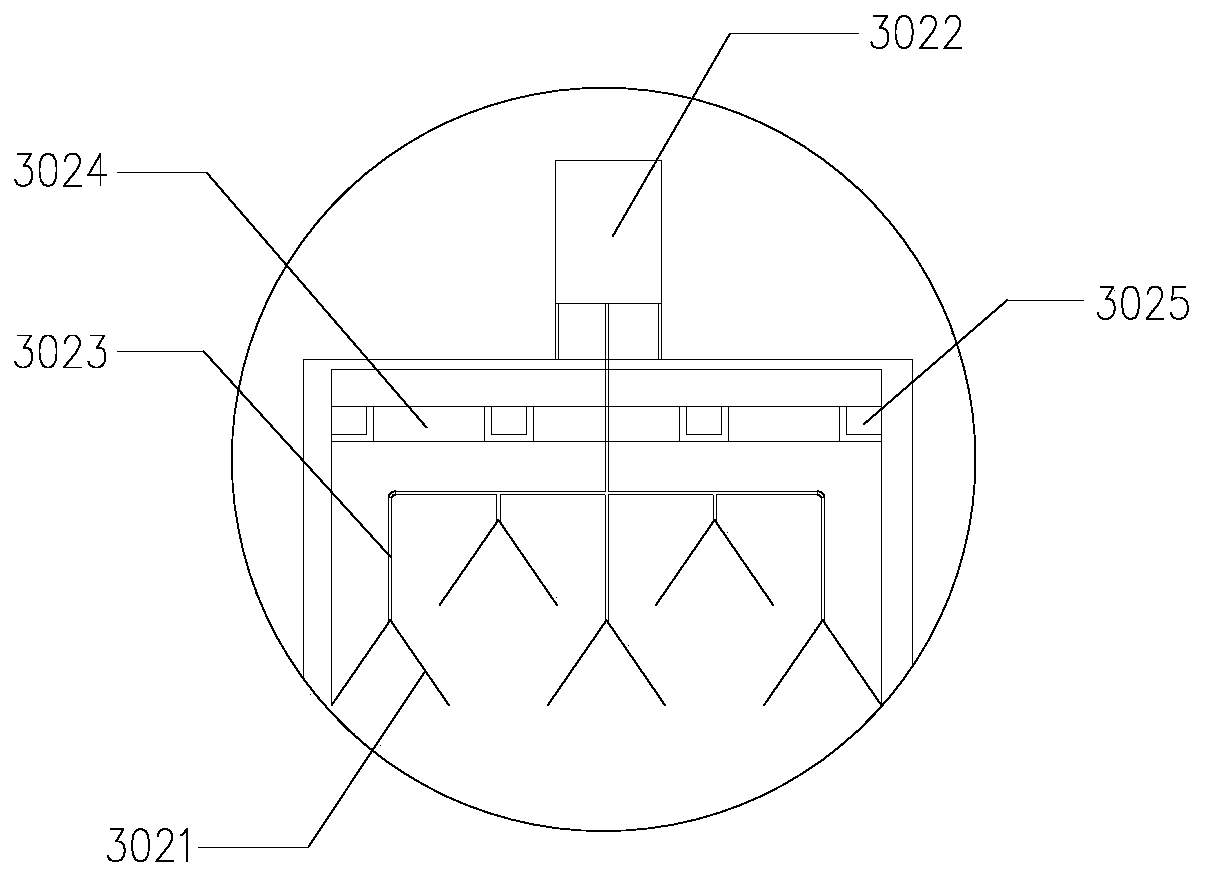

[0038] Such as figure 1 As shown, a high-alkalinity high-concentration printing and dyeing wastewater anaerobic pretreatment system adopted in each embodiment of the present invention includes a high-concentration wastewater regulating tank 1 connected in sequence, a high-pressure microbubble CO 2 Absorption tower 2 and anaerobic reactor 3, high pressure microbubble CO 2 Absorber and CO 2 Storage system connection, CO 2 The storage system consists of liquid CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com