Method of recovering cobalt from lithium ion battery and cobalt recovering system

A lithium-ion battery and recovery method technology, which is applied in the field of recovery of valuable metals in rechargeable batteries, can solve problems such as increased operating costs, difficulty in stabilizing high cobalt recovery rates, and increased risk of cobalt recovery operations, so as to improve safety Sexuality and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the cobalt recovery method and the cobalt recovery system in the lithium ion battery according to the present invention will be described in detail with reference to the accompanying drawings. Also, the present invention cannot be limited by this Example.

[0045] First, a method for recovering cobalt in a lithium ion battery in an example of the present invention will be described in detail.

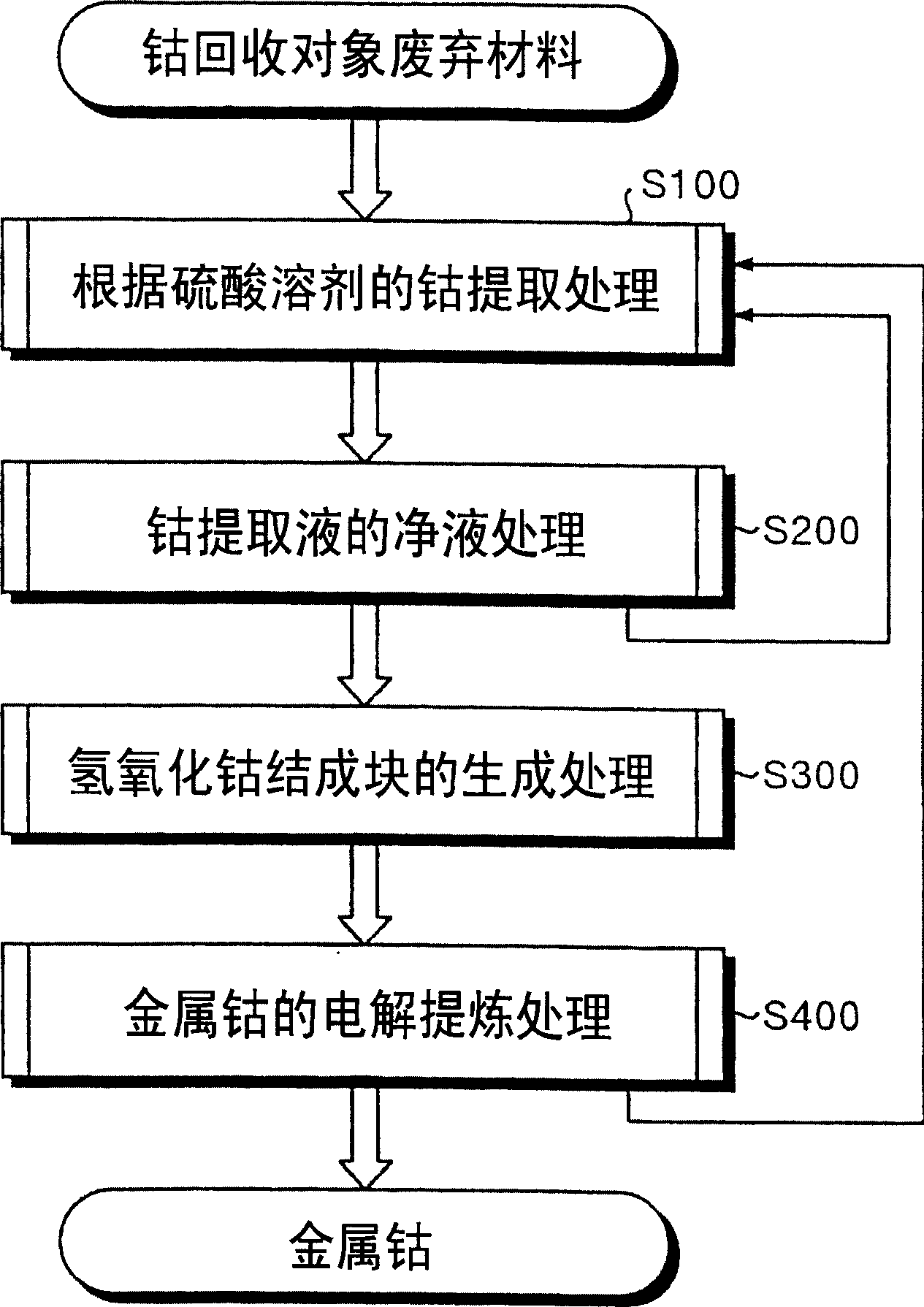

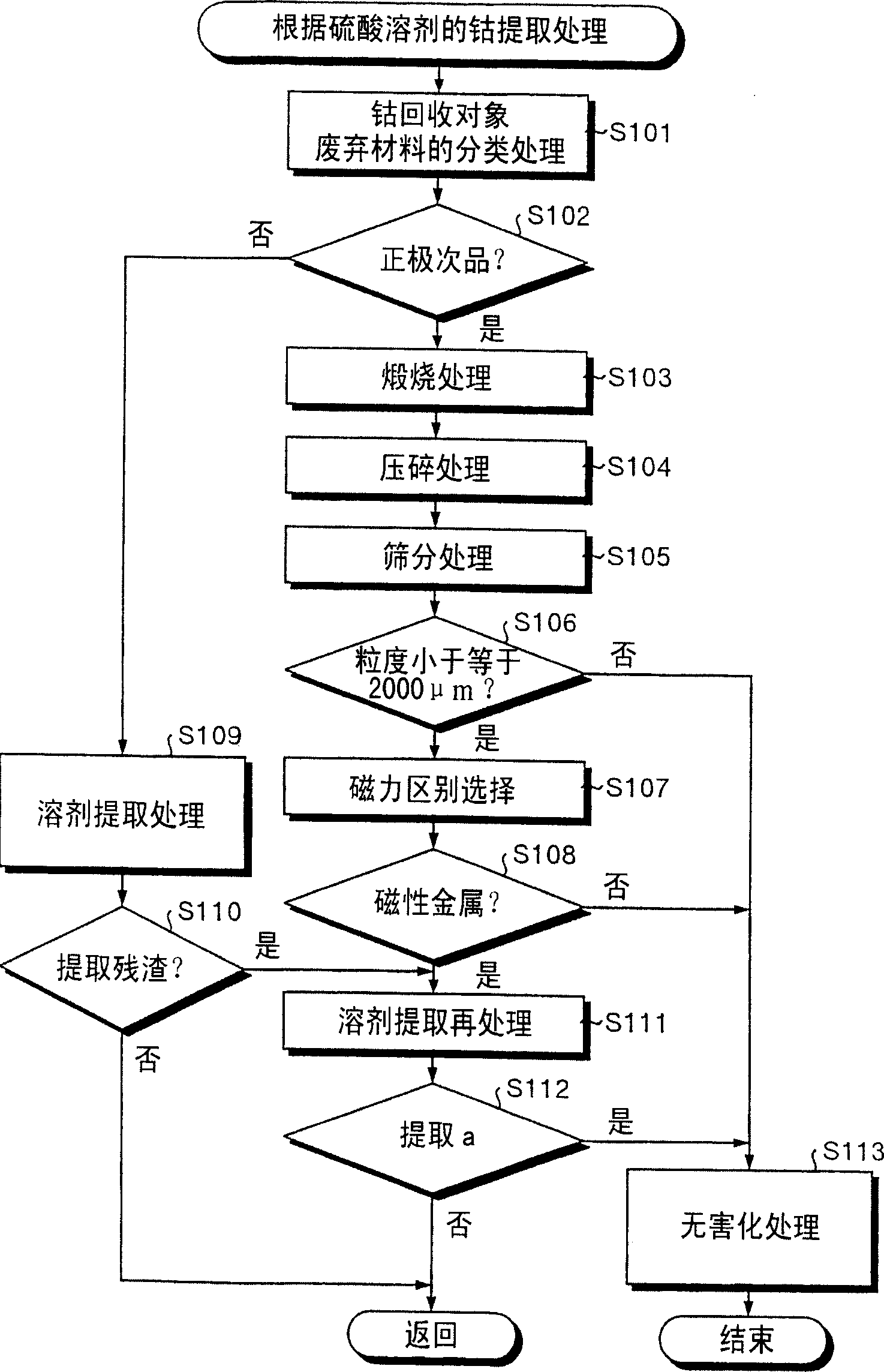

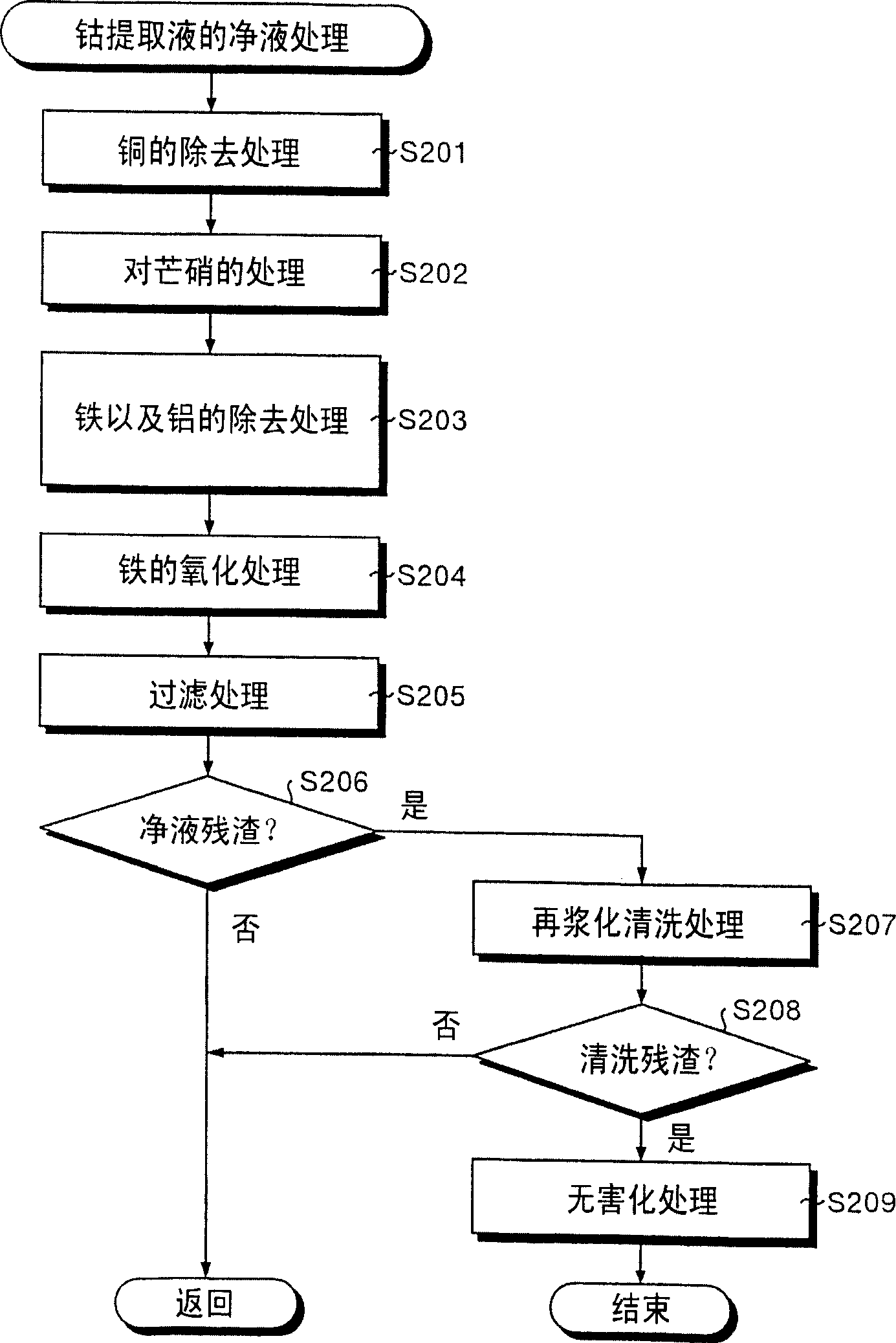

[0046] figure 1 It is a flow chart showing the process of recovering metal cobalt from recycling objects such as discarded lithium-ion batteries and defective positive electrodes according to the method for recovering cobalt in lithium-ion batteries according to the embodiment of the present invention. and in figure 1 In the figure, the thick line arrows indicate the treatment process of recovering metallic cobalt after extracting and separating cobalt from the cobalt recovery target according to each treatment; the thin line arrows indicate the trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com