Zero emission process for treating titanium chloride slag

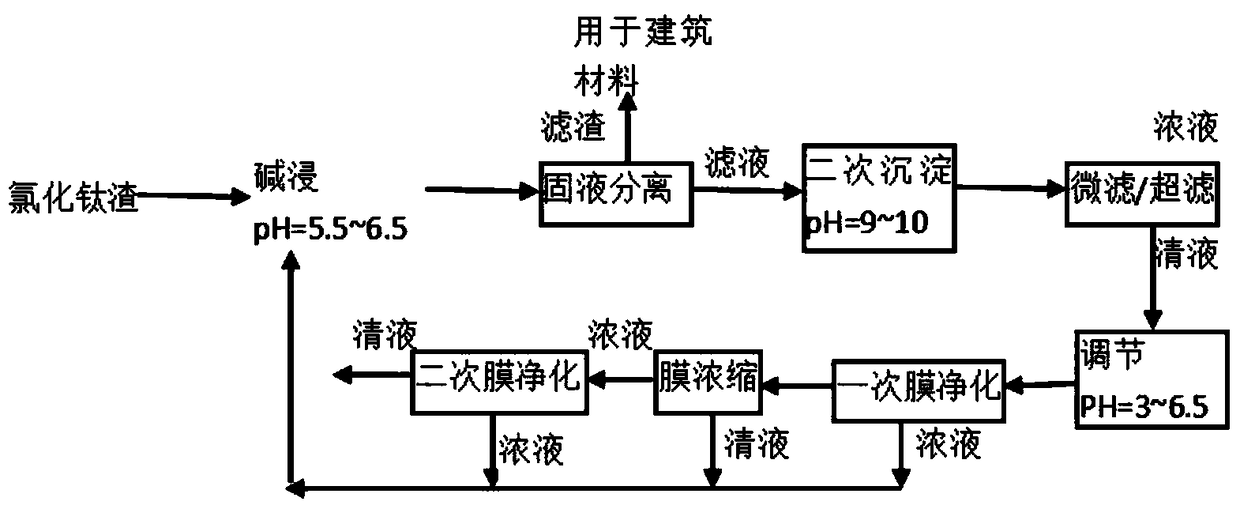

A titanium chloride, zero-discharge technology, applied in the direction of precipitation treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of unreachable, incomplete precipitation, high content, etc., achieve stable membrane concentration process, improve reliability Concentrated Concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Alkali leaching: leaching 60kg of titanium chloride slag with sodium hydroxide alkaline solution, while adjusting pH = 6, controlling the solid-liquid ratio to 1:15 (weight ratio), stirring and reacting for 10 hours to form a neutralized slag slurry; Slurry is separated from solid and liquid by plate and frame filter press or centrifuge to obtain solid filter residue, and the filtrate enters the secondary precipitation process. At this time, the content of sodium chloride in the neutralized filtrate is 5361mg / L, and the volume is 850L. Impurities Al, The Si content is 0.146mg / L and 0.404mg / L respectively;

[0037]Secondary precipitation: the clear liquid separated from the solid-liquid by the ceramic membrane of the neutralized slurry is adjusted to pH = 10 with sodium carbonate and sodium hydroxide, and the secondary slurry is formed after stirring for 1 hour, and the secondary slurry is filtered with a ceramic membrane. Control the solid content in the concentrated so...

Embodiment 2

[0040] Alkali leaching: leaching 60kg of titanium chloride slag with sodium hydroxide alkaline solution, while adjusting pH=6.5, controlling the solid-liquid ratio to 1:10 (weight ratio), stirring and reacting for 10 hours to form a neutralized slag slurry; Slurry is separated by plate and frame filter press and ceramic membrane together to obtain solid filter residue, and the filtrate enters the secondary precipitation process. At this time, the content of sodium chloride in the neutralized filtrate is 8041mg / L, and the volume is 500L. Impurities Al and Si contents are 0.163mg / L and 0.507mg / L respectively;

[0041] Secondary precipitation: neutralize the slurry from the solid-liquid separation of the ceramic membrane with sodium carbonate and sodium hydroxide to adjust the pH to 9.5, stir and react for 2 hours to form a secondary slurry, filter the secondary slurry with a ceramic membrane, Control the solid content in the concentrated solution to 2%, return the concentrated s...

Embodiment 3

[0044] Alkali leaching: leaching 60kg of titanium chloride slag with sodium hydroxide alkaline solution, while adjusting pH=5.5, controlling the solid-liquid ratio to 1:12 (weight ratio), stirring and reacting for 10 hours to form a neutralized slag slurry; The slurry is separated from solid and liquid by centrifuge to obtain solid filter residue, and the filtrate enters the secondary precipitation process. At this time, the content of sodium chloride in the neutralization filtrate is 6701mg / L, the volume is 700L, and the content of impurities Al and Si are 0.12mg respectively / L, 0.38mg / L;

[0045] Secondary precipitation: The clear liquid separated from the solid-liquid by the ceramic membrane of the neutralized slurry is adjusted to pH = 9.5 with sodium carbonate and sodium hydroxide, and the secondary slurry is formed after stirring for 1 hour, and the secondary slurry is filtered with a ceramic membrane. Control the solid content in the dope to 2.5%, return the dope to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com