Special biomass carbon-based fertilizer for leaf vegetables and preparation method thereof

A technology of biomass charcoal and leafy vegetables, applied in the fields of application, nitrogen fertilizer, potassium fertilizer, etc., can solve the problems of excessive nitrate content of crops, substandard fertilizer hardness, loss of ammoniacal nitrogen fertilizer, etc., achieve good bonding effect, prevent soil Effect of salinization and particle hardness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

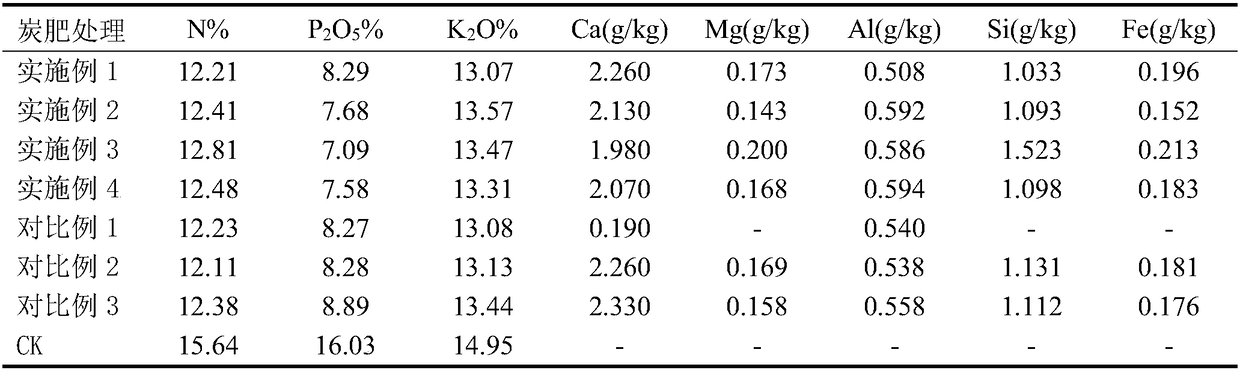

Embodiment 1

[0029] A special biochar-based fertilizer for leafy vegetables, comprising the following raw materials in parts by weight: 245 parts of urea, 260 parts of potassium sulfate, 180 parts of monoammonium phosphate, 50 parts of superphosphate, 200 parts of biochar, and 40 parts of filler , 25 parts of adhesion promoter, wherein, the biochar will be sprayed with wood vinegar, the filler is talcum powder, and the adhesion promoter is a mixture of bentonite and ammonium bicarbonate, the mass of the two The ratio is 1.5:1.

[0030] Its preparation method comprises the following steps:

[0031] (1) Preparation of biochar: steps such as comprising material selection, material granulation, continuous feeding carbonization, multistage cooling, wood vinegar spraying: wherein the carbonization process is an anaerobic condition, and the wood vinegar spraying is at Spray the wood vinegar produced by the carbonization process when the carbonization finishes in the cooling chamber, and the spra...

Embodiment 2

[0036] A special biochar-based fertilizer for leafy vegetables, comprising the following raw materials in parts by weight: 255 parts of urea, 270 parts of potassium sulfate, 160 parts of monoammonium phosphate, 45 parts of superphosphate, 200 parts of biochar, and 50 parts of filler , 20 parts of adhesion promoter, wherein, the biochar will be sprayed with wood vinegar, the filler is talcum powder, and the adhesion promoter is a mixture of bentonite and ammonium bicarbonate, the mass of the two The ratio is 1.3:1.

[0037] Its preparation method comprises the following steps:

[0038] (1) Preparation of biochar; steps such as material selection, material granulation, continuous feed carbonization, multistage cooling, wood vinegar spraying: wherein the carbonization process is an anaerobic condition, and the wood vinegar spraying refers to Spray with the wood vinegar that the carbonization process produces when carbonization finishes to cooling room, and the spraying amount of w...

Embodiment 3

[0043] A special biochar-based fertilizer for leafy vegetables, comprising the following raw materials in parts by weight: 265 parts of urea, 260 parts of potassium sulfate, 155 parts of monoammonium phosphate, 40 parts of superphosphate, 200 parts of biochar, and 50 parts of filler , 30 parts of adhesion promoter, wherein, the biochar will be sprayed with wood vinegar, the filler is talcum powder, the adhesion promoter is a mixture of bentonite and ammonium bicarbonate, the mass of the two The ratio is 1.5:1.

[0044] Its preparation method comprises the following steps:

[0045] (1) Preparation of biochar; steps such as material selection, material granulation, continuous feed carbonization, multistage cooling, wood vinegar spraying: wherein the carbonization process is an anaerobic condition, and the wood vinegar spraying refers to Spray with the wood vinegar that the carbonization process produces when carbonization finishes to cooling chamber, and the spraying amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com