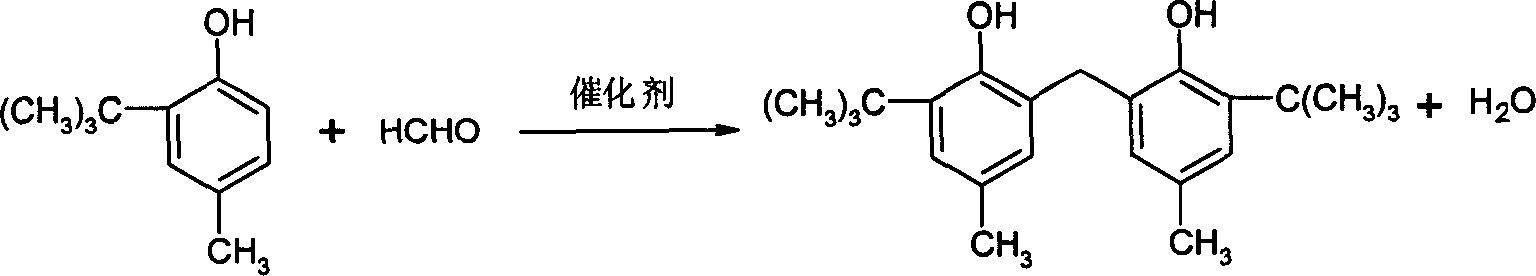

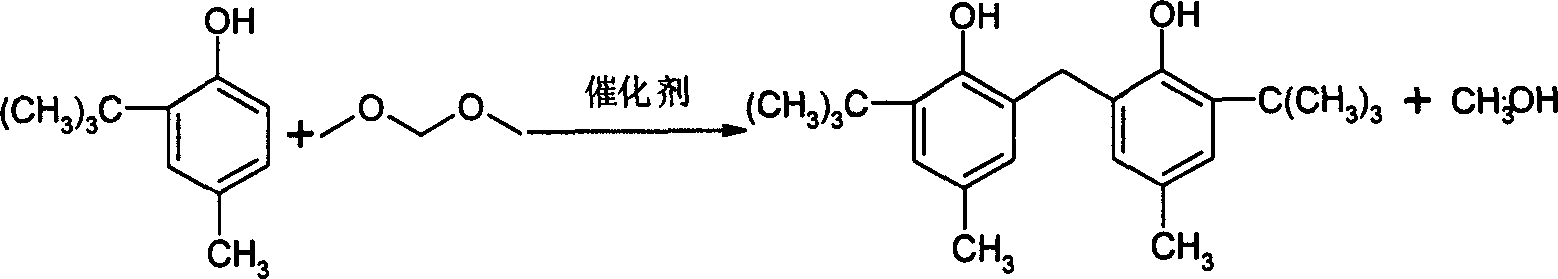

Prepn process of 2,2'-methylene bis (4-methyl-6-tert-butyl phenol)

A technology of tert-butylphenol and methylene bis, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of strong corrosiveness, increase the post-processing process and preparation cost, and does not involve the stability of resin catalysts. Sexual issues etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Resin catalyst:

[0022] Macroporous strongly acidic (-SOH) based on styrene-divinylbenzene copolymer 3 ) cation exchange resin, the exchange capacity is 4.3 milliequivalents / g, the average pore diameter of the resin is 205 angstroms, the resin is processed in a vacuum desiccator, the processing temperature is 90 ° C, and the processing time is 3 hours;

[0023] Add 217 milliliters of methylal, 100 grams of 2-tert-butyl-4-cresol (molar ratio 4:1) and 60 grams of the above-mentioned resin catalyst into a stainless steel reactor with stirring. After the reactor is sealed, open Stirrer, react at a reaction temperature of 70°C and a reaction time of 2.5 hours. After the reaction, the reaction product is cooled to room temperature, and the catalyst is separated by filtration. The filtrate is distilled to remove the solvent to obtain a crude reaction product, which is obtained by refining 2,2'-methylenebis(4-methyl-6-tert-butylphenol) product.

[0024] The yield of the prod...

Embodiment 2

[0027] Resin catalyst:

[0028] Macroporous strongly acidic (-SOH) based on styrene-divinylbenzene copolymer 3 ) a cation exchange resin with an exchange capacity of 4.8 milliequivalents / gram and an average resin pore diameter of 350 angstroms. The resin is treated in a vacuum desiccator at a treatment temperature of 105° C. and a treatment time of 2 hours;

[0029]Add 163 milliliters of methylal, 100 grams of 2-tert-butyl-4-cresol (molar ratio 3:1) and 50 grams of resin catalyst into a stainless steel reactor with stirring. After the reactor is sealed, start stirring device, reacted at a reaction temperature of 75° C. and a reaction time of 3 hours. After the reaction, the aftertreatment of the reaction product was the same as in Example 1.

[0030] The yield of the product is 98%, the melting point of the product is 129-130°C, and the purity of the product is 98%.

[0031] The separated resin catalyst was put back into the reactor, and the reaction was continued according ...

Embodiment 3

[0033] AmberlystXN-1005 strongly acidic (-SOH 3 ) Macroporous cation exchange resin with a resin exchange capacity of 3.5 milliequivalents / g and an average pore diameter of 80 angstroms. The resin is treated in a vacuum dryer at a treatment temperature of 100° C. and a treatment time of 2 hours;

[0034] Add 271 milliliters of methylal, 100 grams of 2-tert-butyl-4-cresol (molar ratio 5:1) and 50 grams of resin catalyst into a stainless steel reactor with stirring. After the reactor is sealed, start stirring device, reacted at a reaction temperature of 80° C. and a reaction time of 2 hours. After the reaction, the aftertreatment of the reaction product was the same as in Example 1.

[0035] The yield of the product is 85%, and the melting point of the product is 128-129°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com