Externally heating type wet flue gas dehumidifying method and system

A technology for heating, dehumidifying, and humid flue gas, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., and can solve the problems of low service life of flue gas heat exchangers, white smoke, and high heating costs of low-temperature wet flue gas. Achieve the effect of small system site area, prolong service life and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

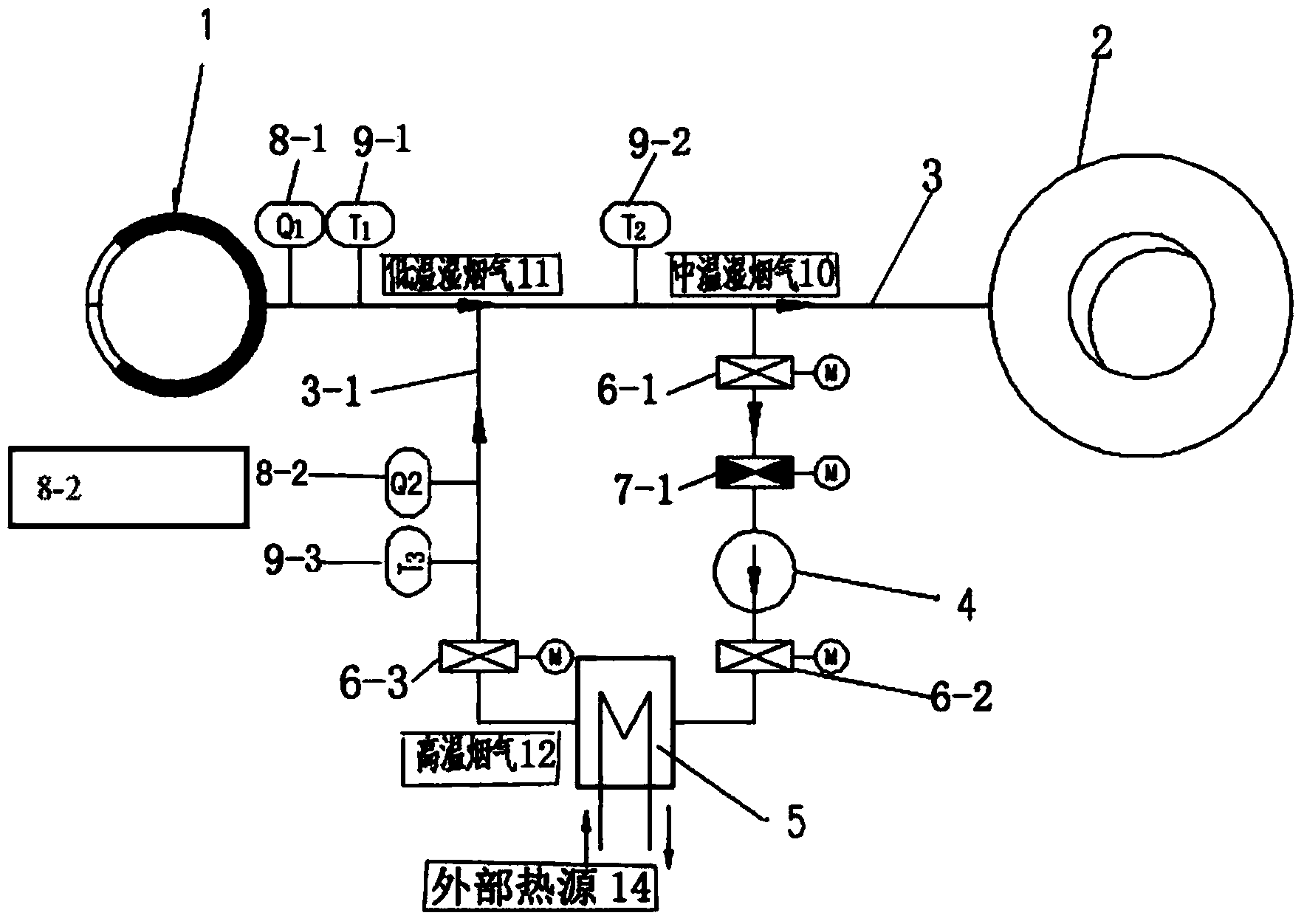

[0031] refer to figure 1, The external heated wet flue gas dehumidification system involved in this embodiment includes a desulfurization absorption tower 1, a chimney 2, a main flue 3, a pressurized fan 4, an external steam heat exchanger 5, and a first switch valve 6-1 , the second switching valve 6-2, the third switching valve 6-3, the first flow regulating valve 7-1, the first flow detector 8-1, the second flow detector 8-2, the first temperature detector 9 -1, the second temperature detector 9-2, the third temperature detector 9-3 and an external heat source 14, the desulfurization absorption tower 1 is connected to the chimney 2 through the main flue 3, and is close to the chimney on the main flue 3 The smoke outlet is set at the 2nd end, and the smoke inlet is set at the 1st end of the desulfurization absorption tower. The smoke outlet is connected to the air inlet end of the pressurized fan 4 through the first switching valve 6-1 and the first flow regulating valve 7-1...

specific Embodiment 2

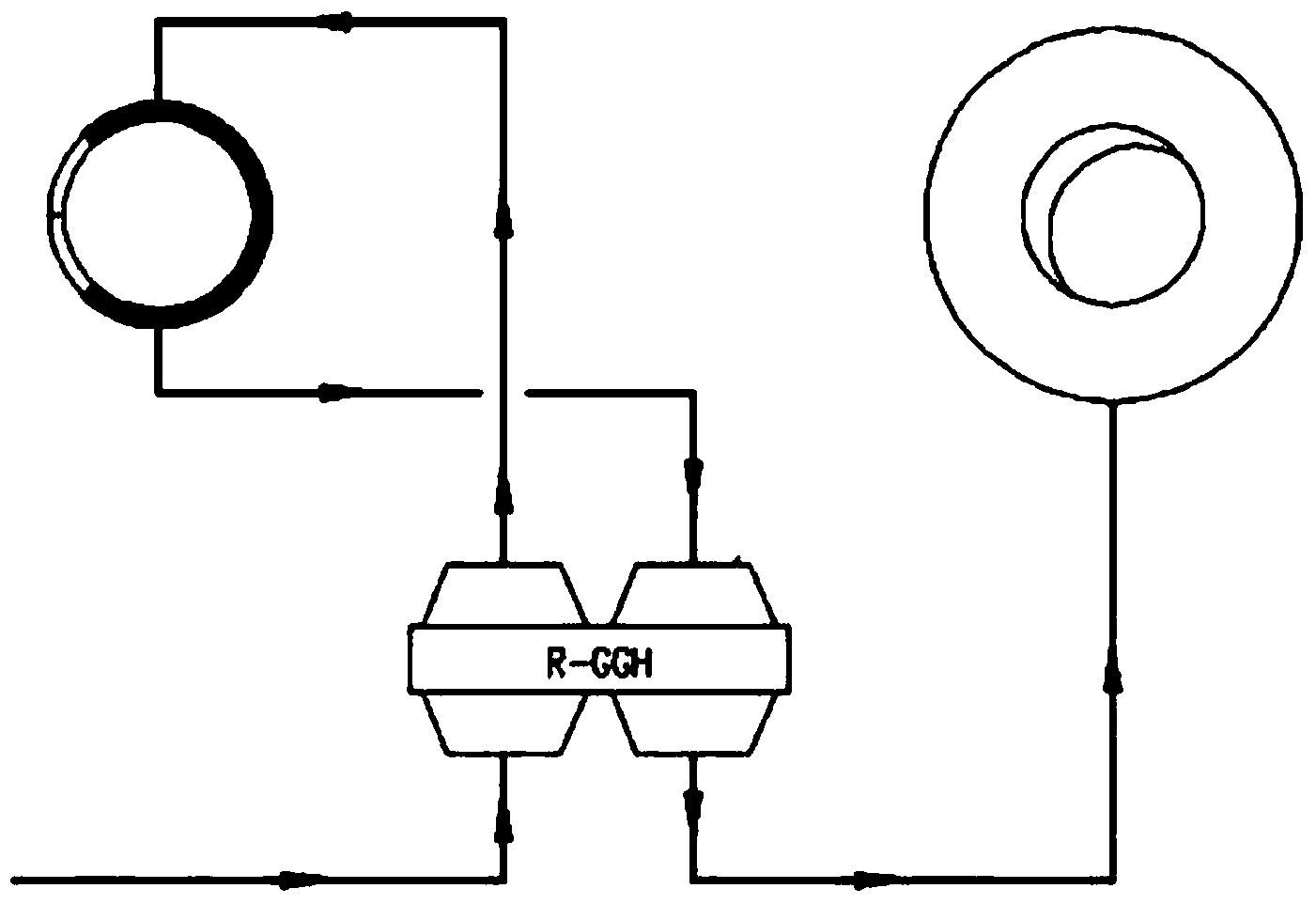

[0043] The characteristics of this embodiment 2 are: the external heating type wet flue gas dehumidification system also includes a mixing chamber and filter screen, the main flue 3 is provided with a mixing chamber, the mixing chamber and the external heating type wet flue gas dehumidification The system is connected, and the external heated wet flue gas dehumidification system extracts air 13 through the pressurized fan 4, heats the air 13 through the external steam heat exchanger 5, and the heated air 12 enters the mixing chamber and is mixed with the main flue 3 The low-temperature wet flue gas 11 is mixed into medium-temperature flue gas 10, and the first on-off valve 6-1 at the front end of the pressurized fan 4 is replaced with a filter to filter the air 13. All the other are with specific embodiment 1.

specific Embodiment 3

[0044] The feature of this embodiment is that the fourth temperature detector and the fourth flow regulator are installed on the external heat source, and other features are the same as those of the specific embodiment 1.

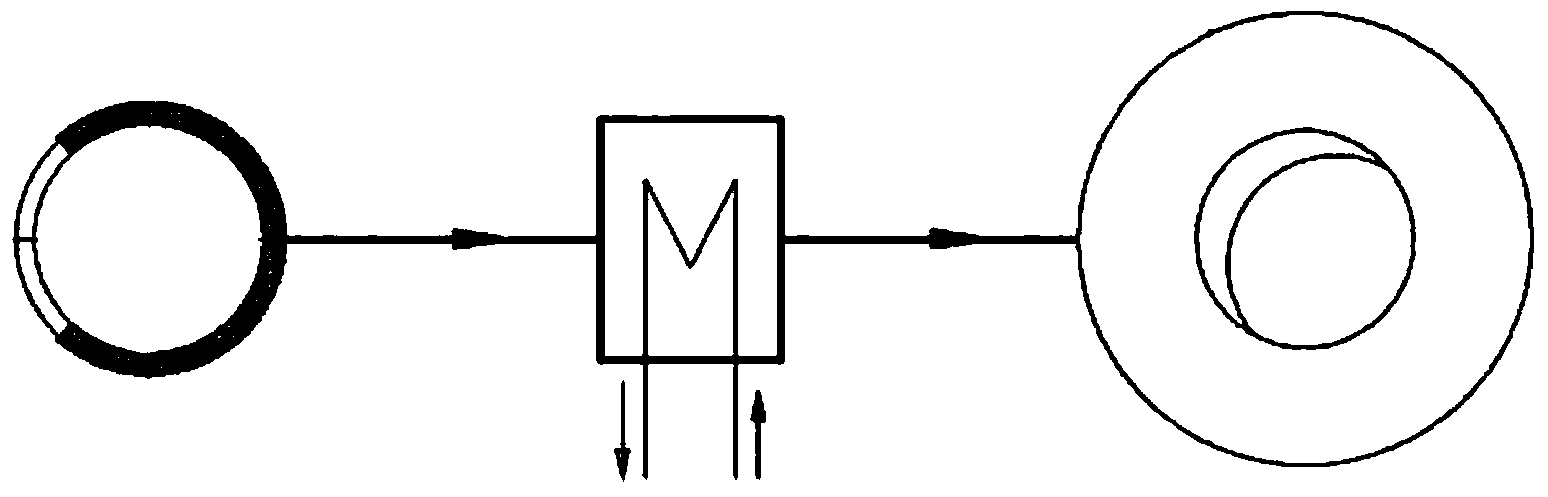

[0045] In this external heating type wet flue gas dehumidification method, the air 13 is absorbed by the pressurized fan 4, the air 13 is heated to 160°C, and then the high-temperature air is input into the main flue 3 and mixed with the low-temperature wet flue gas 11 to form a medium-temperature flue gas 13 , so that the final exhaust gas temperature is higher than the "white smoke" temperature. Other features are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com