Glow ion carbonization method for enhancing surface hardness and corrosion resistance of stainless steel

A technology of glow ion penetration and surface hardness, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., and can solve the problem of stainless steel depassivation film and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

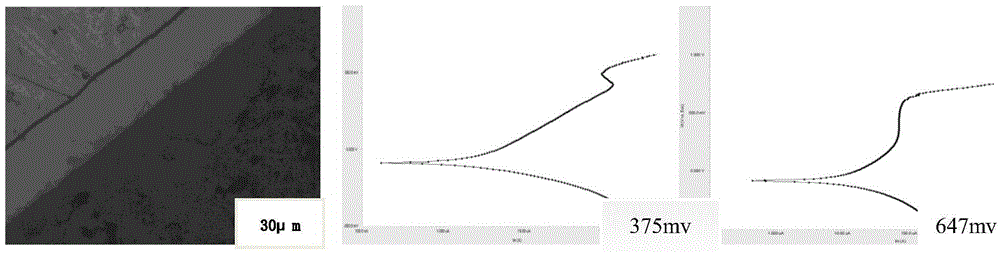

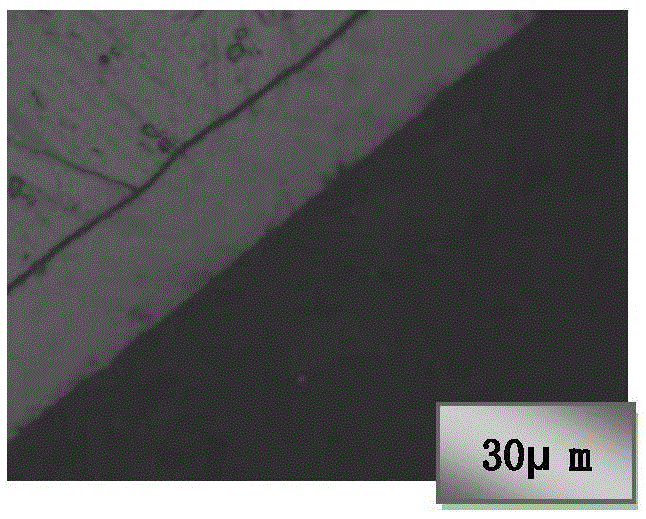

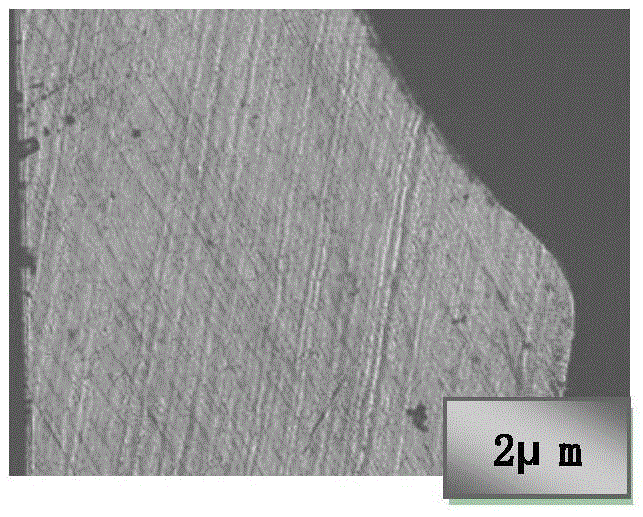

Image

Examples

Embodiment 1

[0042] A glow ion carburizing method for improving the surface hardness and corrosion resistance of stainless steel, comprising the following steps: first degreasing the same batch of 316 stainless steel in an oil-removing solvent at 80°C, soaking for 10 minutes, and cleaning the stainless steel surface with distilled water Liquid, and dry, spare;

[0043] 1) Put the surface clean and dry 316 stainless steel obtained in the above steps on the cathode disc in the carburizing furnace, vacuumize the carburizing furnace, and clean the furnace chamber with high-purity hydrogen for 2 times. After the cleaning is completed, re-carburize The pressure in the furnace is pumped down to below 50Pa;

[0044] 2) Apply a DC pulse high voltage between the cathode disc and the inner wall of the furnace, and fill it with argon until the pressure in the carburizing furnace is 100Pa, and the oxide film on the surface of the stainless steel is removed by glow discharge; arcing is not allowed on th...

Embodiment 2

[0049] A glow ion carburizing method for improving surface hardness and corrosion resistance of stainless steel, comprising the following steps:

[0050] 1) Place clean and dry austenitic stainless steel on the cathode disc in the carburizing furnace, vacuumize the carburizing furnace, and clean the furnace chamber with high-purity hydrogen for 3 times. The pressure is pumped below 50Pa;

[0051] 2) Apply a DC pulse high voltage between the cathode disc and the inner wall of the furnace, and fill it with argon until the pressure in the carburizing furnace is 200Pa, and the oxide film on the surface of the stainless steel is removed by glow discharge; arcing is not allowed on the surface of the workpiece, and the glow During the photodischarge process, the temperature of the stainless steel also rises at the same time;

[0052] 3) When the temperature of the stainless steel rises to the carburizing temperature, turn off the argon source, and pass a carbon-containing reducing g...

Embodiment 3

[0056] A glow ion carburizing method for improving surface hardness and corrosion resistance of stainless steel, comprising the following steps:

[0057] 1) Place clean and dry austenitic stainless steel on the cathode disk in the carburizing furnace, vacuumize the carburizing furnace, and clean the furnace chamber with high-purity hydrogen for 2-3 times. After cleaning, re-carburize The pressure in the furnace is pumped down to below 50Pa;

[0058] 2) Apply a DC pulse high voltage between the cathode disc and the inner wall of the furnace, and fill it with argon until the pressure in the carburizing furnace is 150Pa, and the oxide film on the surface of the stainless steel is removed by glow discharge; arcing is not allowed on the surface of the workpiece, and the glow During the photodischarge process, the temperature of the stainless steel also rises at the same time;

[0059] 3) When the temperature of the stainless steel rises to the carburizing temperature, turn off the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com