Precise water system descaling agent and preparation method thereof

A descaling agent and sophisticated technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve problems such as the decrease of heat exchange efficiency of equipment, affect the normal use of equipment, and complicated operation, and achieve descaling. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described by the following examples, but not as a limitation of the present invention.

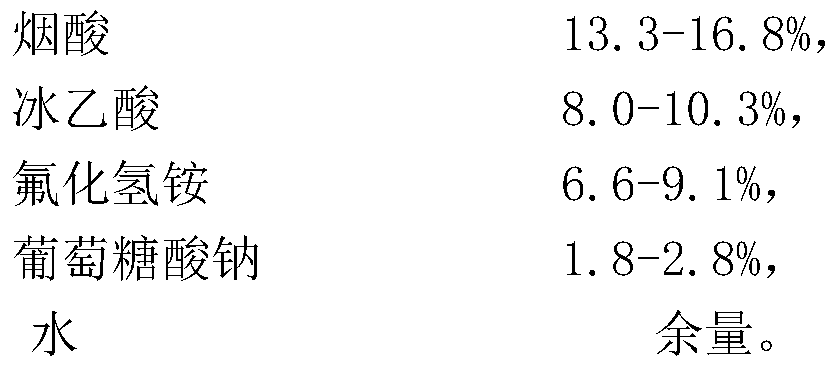

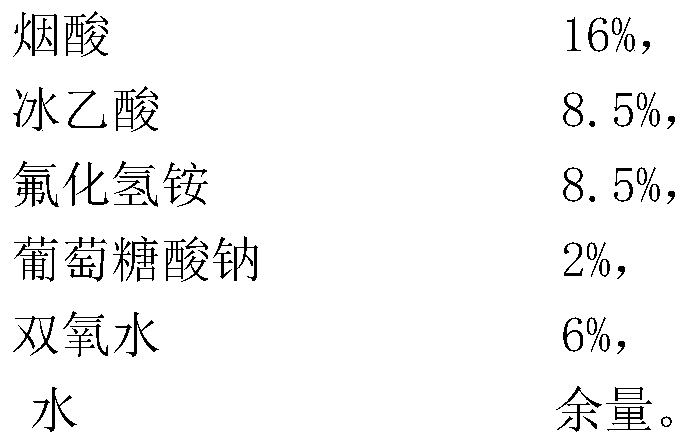

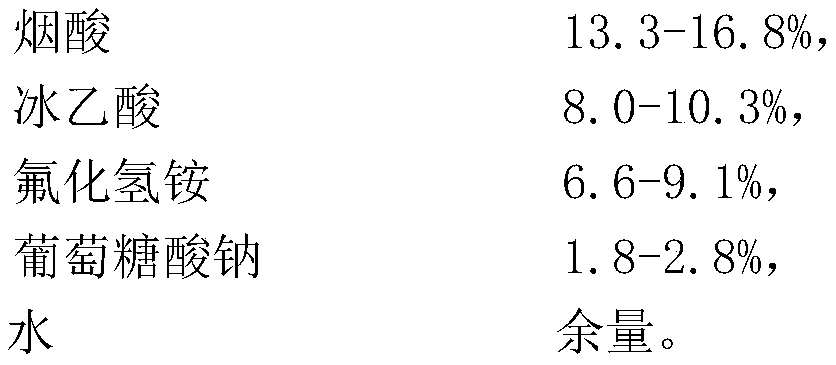

[0017] Table 1 shows the formulations of Examples 1-4 and Comparative Examples 1-2, and the unit is wt%.

[0018] The formula of table 1 embodiment 1-4, comparative example 1-2

[0019]

[0020] The preparation method of the above precision water system descaling agent: weigh each component, blend, stir and dissolve evenly.

[0021] The method of using the descaling agent for the precision water system is as follows: soak the equipment (boiler) to be descaled in the above descaling agent for the precision water system, take it out after all the dirt falls off, and rinse it with clean water.

[0022] Above embodiment, the use effect of comparative example are as follows:

[0023]

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com