Patents

Literature

224 results about "Acidum Nicotinicum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acidum Nicotinicum. Acidum Nicotinicum may be available in the countries listed below. Ingredient matches for Acidum Nicotinicum Nicotinic Acid. Nicotinic Acid is reported as an ingredient of Acidum Nicotinicum in the following countries:. Hungary

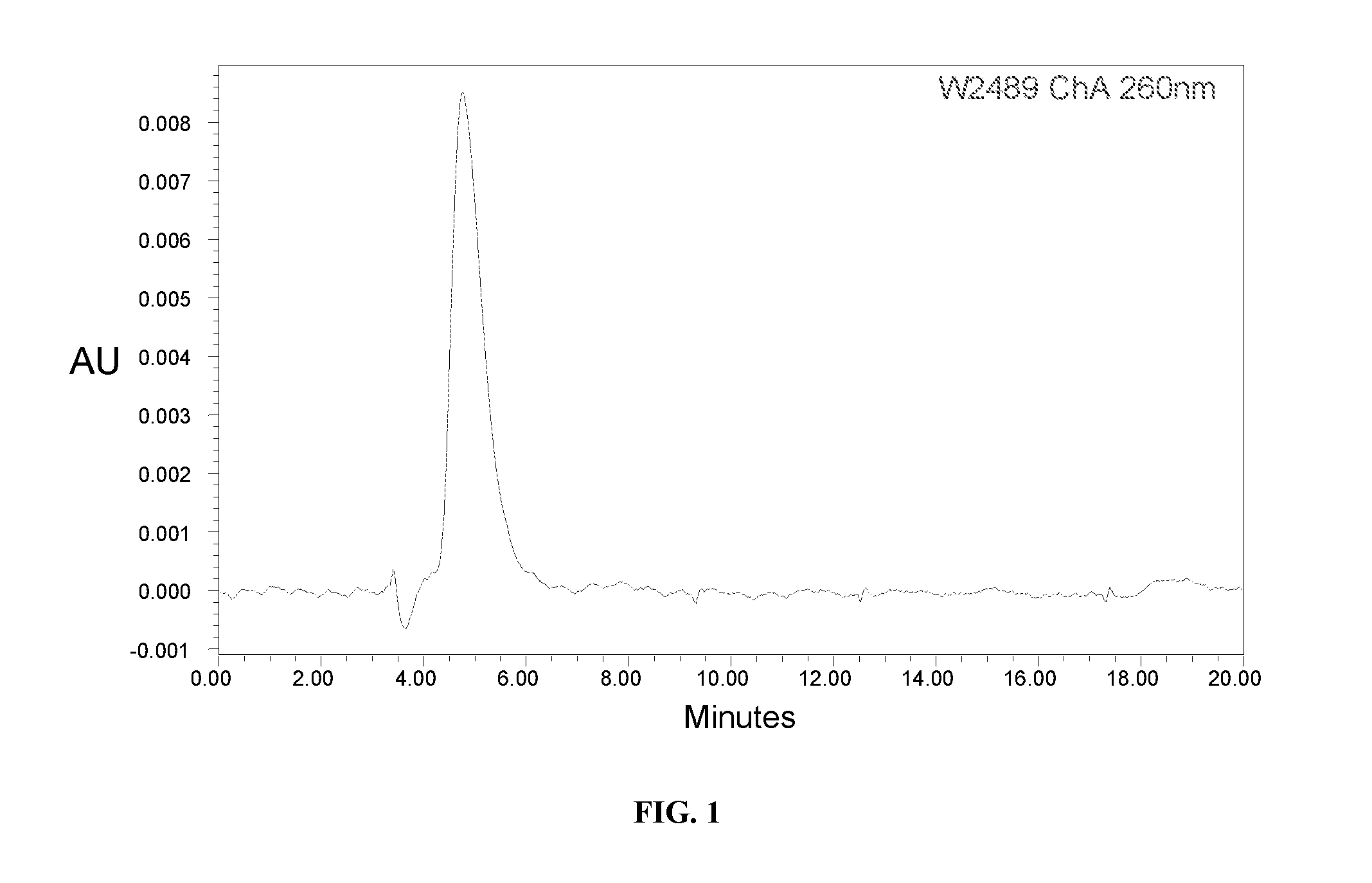

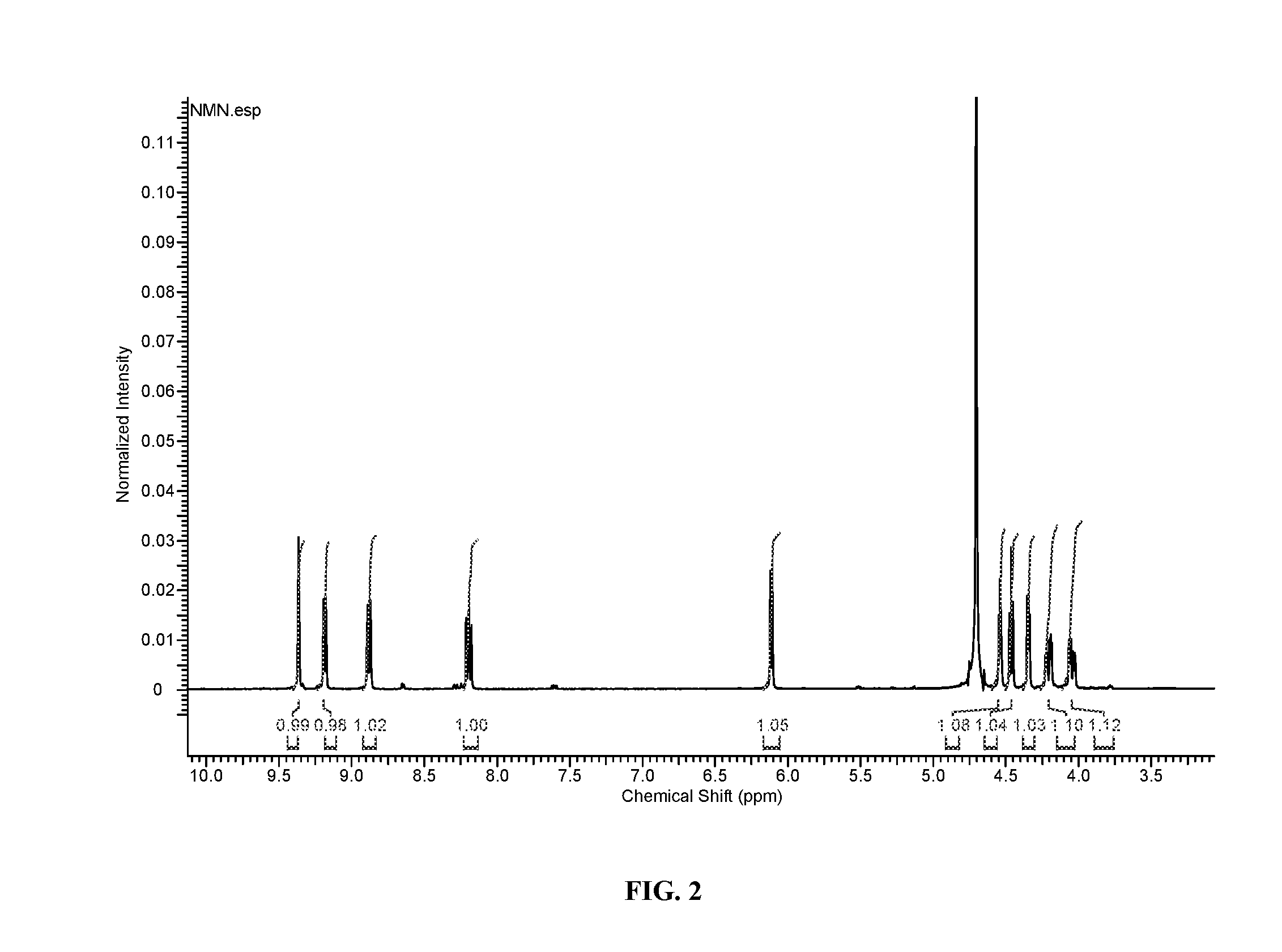

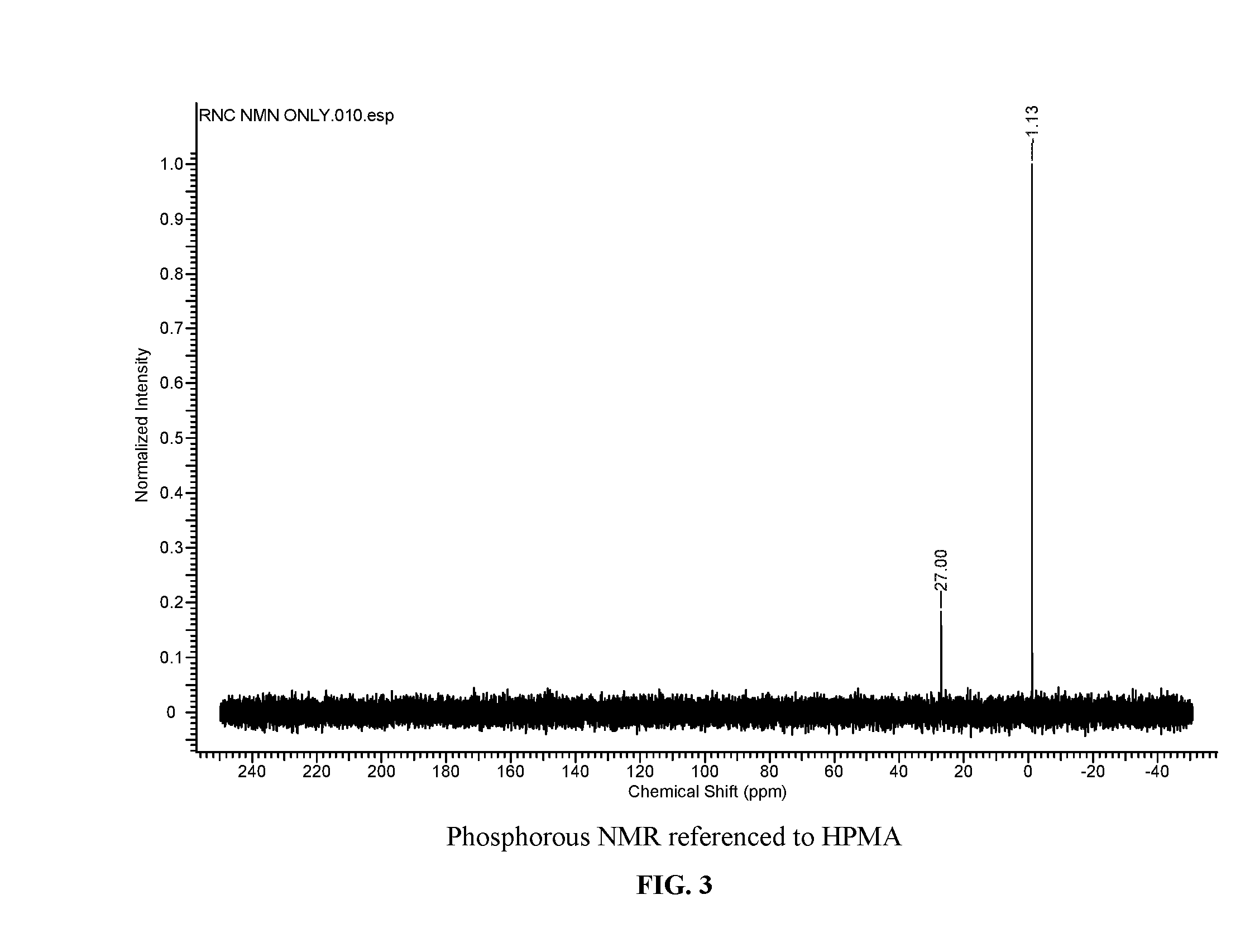

Selective solvent free phosphorylation

A synthetic process is provided for the preparation of phosphorylated analogs of nicotinamide riboside (“NR”) having the formula (I), or salts thereof, and reduced or modified derivatives thereof, having the formula (II), wherein X−, Y1, Y2, Z1, Z2, n, R1, R2, R3, R4, R5, R6, and R7 are as defined herein. The present disclosure also relates to the preparation of phosphorylated analogs of nicotinic acid riboside (“NAR”) having the formula (I), or salts thereof, and reduced or modified derivatives thereof, having the formula (II). Generally solvent-free conditions are employed using appropriate mechano-chemical techniques as described.

Owner:QUEENS UNIV OF BELFAST +1

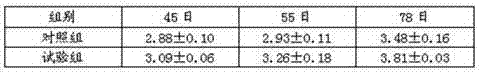

Mineral substance composite licking brick for cattle and sheep and its preparing process

The present invention provides a mineral compound type licking brick for cattle and sheep and its preparation method. Every kg of licking brick contains 0.15-0.3g of ferrous sulfate, 0.15-0.3g of zinc sulfate, 0.1-0.2g of copper sulfate, 0.2-0.3g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.3g of potassium iodide, 0.03-0.08g of cobaltous chloride, 0.1-0.3g of magnesium oxide, 0.02-0.03g of nano zinc oxide and copper sulfate mixture, 6-10g of chromium nicotinate, 30-150g of sodium sulfate, 40-100g of calcium hydrogen phosphate, 200-400g of edible salt, 200-400g of solidifying agent, 50-200g of carrier and 30-70g of treacle.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

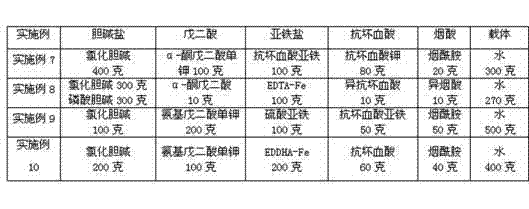

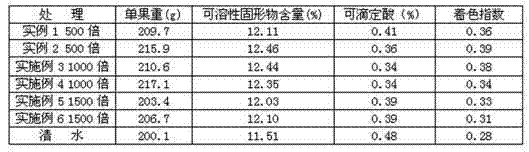

Agricultural composition with function of sugar increase and coloring of fruit

InactiveCN103609593AHigh soluble solids contentGood coloring effectBiocidePlant growth regulatorsGlutaric acidSugar

The invention relates to an agricultural composition with functions of sugar increase and coloring of fruit. The composition comprises choline salt, glutaric acid and / or a derivative of glutaric acid, ferrite, ascorbic acid and / or a derivative of ascorbic acid, and nicotinic acid and / or a derivative of nicotinic acid, wherein the choline salt accounts for 10-60% of the weight of the final composition; the glutaric acid and / or the derivative of the glutaric acid accounts for 5-30% of the weight of the final composition; the ferrite accounts for 10-60% of the weight of the final composition; the ascorbic acid and / or the derivative of the ascorbic acid accounts for 1-20% of the weight of the final composition; the nicotinic acid and / or the derivative of the nicotinic acid accounts for 1-20% of the weight of the final composition. By adopting the agricultural composition with the functions of the sugar increase and coloring of the fruit, not only can the soluble solid content of fruit be increased, but also anthocyanin generation is prompted, and meanwhile the functions of sugar increase and coloring are achieved, and manpower and material resources required by using a sugar increasing agent and a colorant respectively used are saved.

Owner:HEBEI ACAD OF FORESTRY SCI

Nourishing healthcare liquid and its production method

A formulation of a nutrient healthful liquid and its production method. The liquid containing many nutriments, such as coenzyem Q, VA,VB1,VB2, VC, VD, VE and nicotinic acid. The method comprises: mixing the above-mentioned materials, blending, homogenizing, expelling gases, disinfecting and packing. The healthful liquid has balanced nutriments, could be easily absorbed by human bodies.

Owner:XIAN LIJUN PHARMA CO LTD

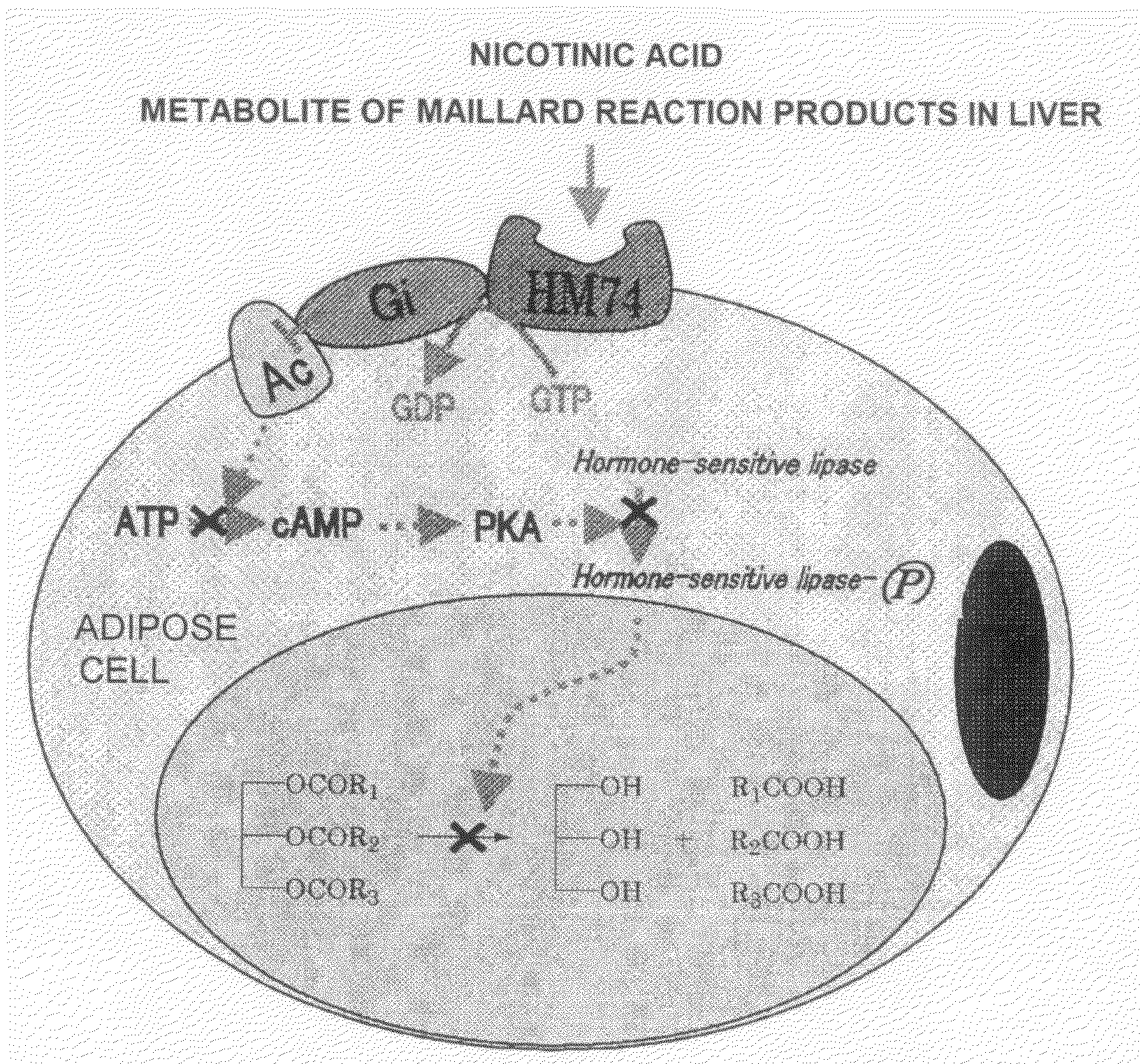

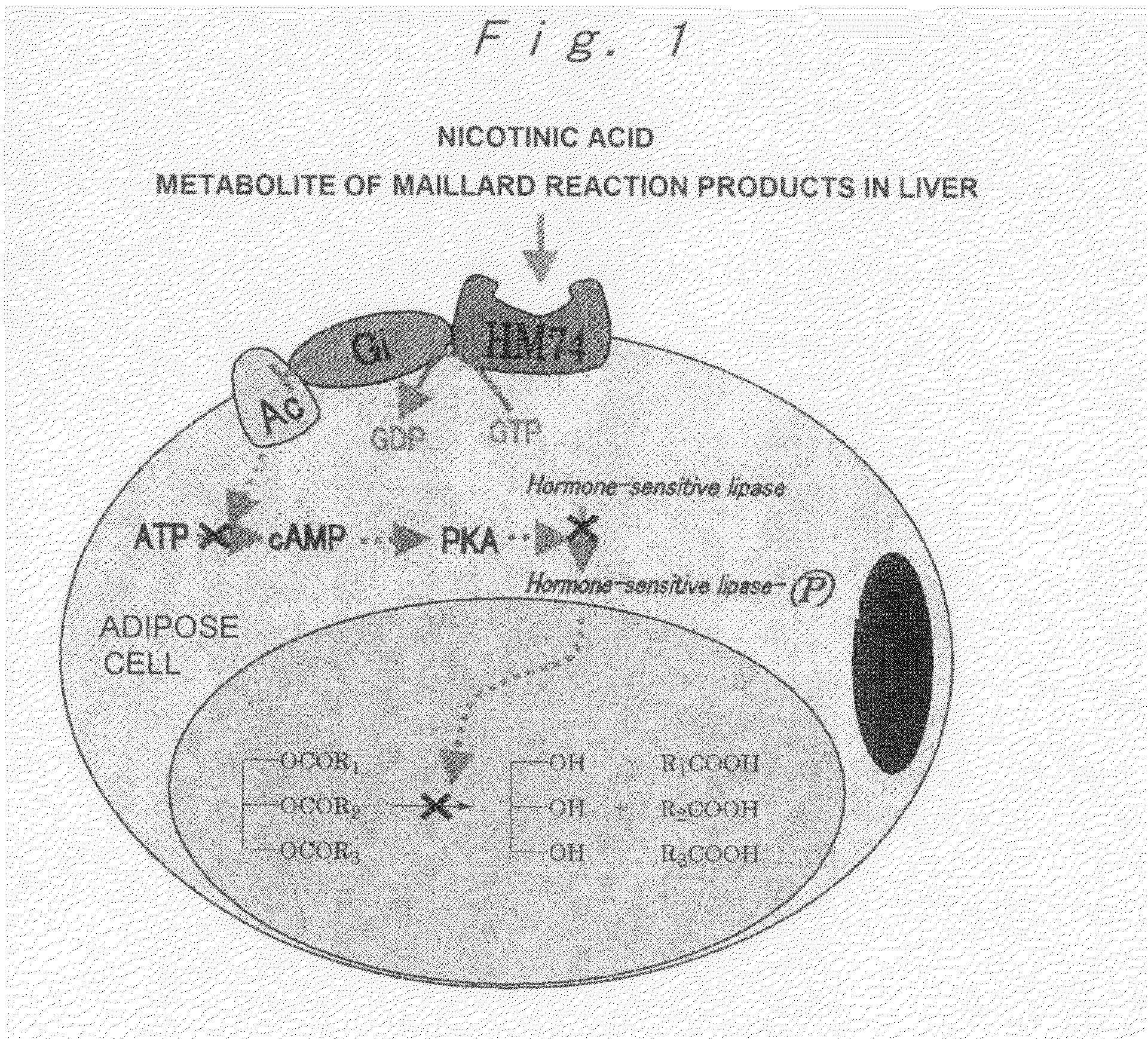

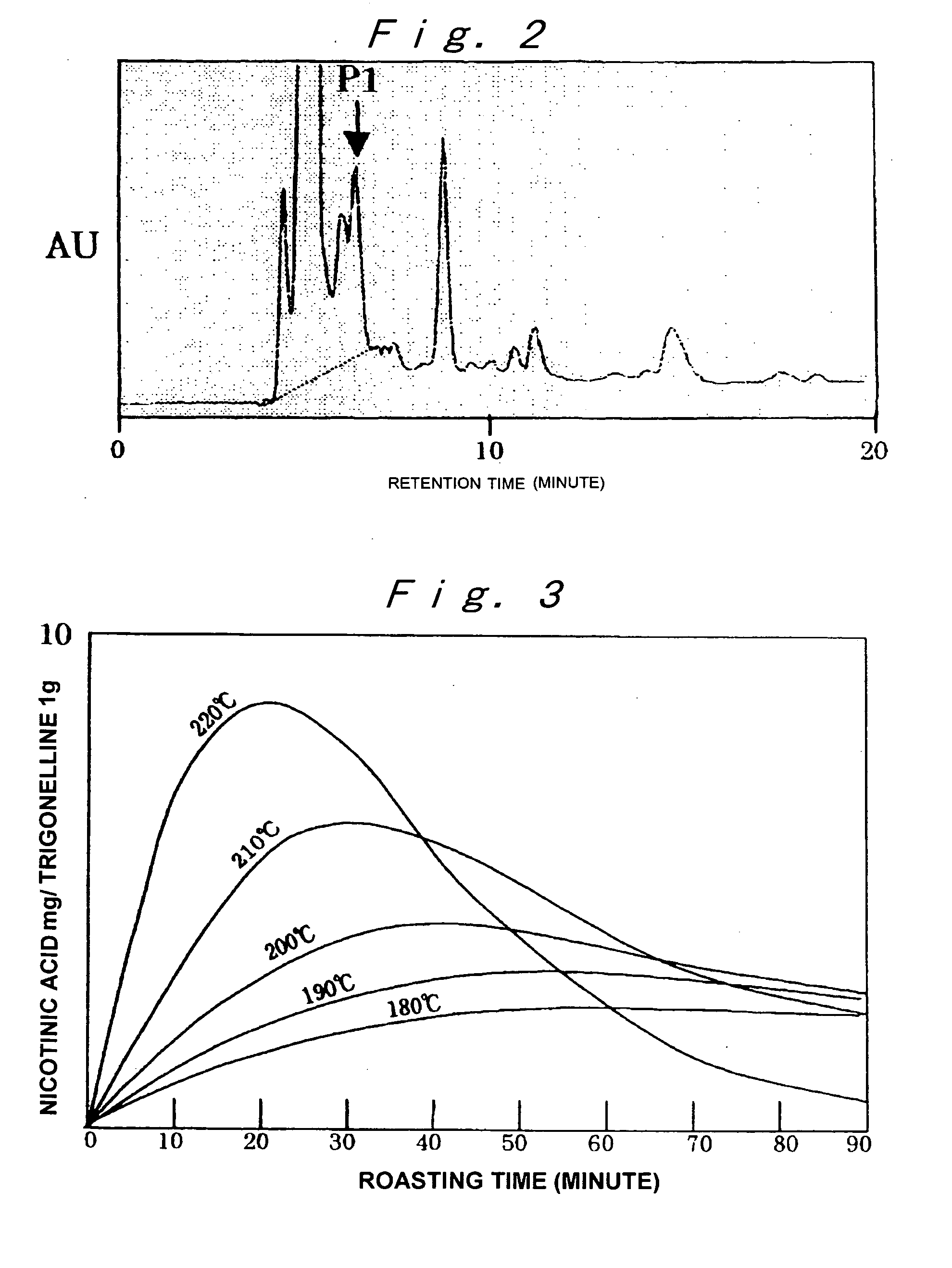

Modified Coffee, Method of Roasting Coffee Bean, Coffee-Like Supplement and Auxiliary Food

InactiveUS20080227832A1Reduce the amount requiredRaise the ratioBiocideMetabolism disorderMaillard reactionMetabolite

A modified coffee containing 3 mg or more of a nicotinic acid compound and 10 mg or more of a Maillard reaction product per 10 g of roasted coffee beans. A coffee-like supplement containing at least one nicotinic acid compound, at least one Maillard reaction product, and / or at least one metabolite of the Maillard reaction product.

Owner:TAMA TLO LTD

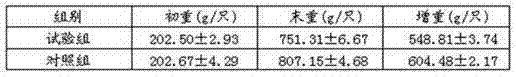

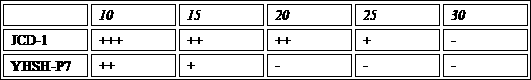

Pseudomonas putida and method for producing nicotinic acid or isonicotinic acid through converting Pseudomonas putida

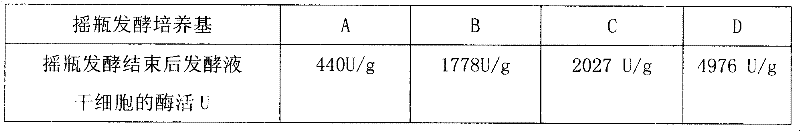

ActiveCN102337233AShort growth cycleImprove conversion efficiencyBacteriaMicroorganism based processesEnvironmentally friendlyNitrilase activity

The invention discloses a new bacterial strain CGMCC3830 (Pseudomonas putida) and a method for catalytically producing nicotinic acid or isonicotinic acid by using the bacterial strain. In the invention, the nicotinic acid or isonicotinic acid is obtained through a hydrolysis reaction, wherein 3-cyanopyridine and 4-cyanopyridine are taken as raw materials, and the CGMCC3830 (Pseudomonas putida) with high nitrilase activity obtained through fermentation culture is taken as a catalyst. The method comprises the following steps of: adding a substrate in a reactor in a flowing mode, and reacting for 6-10 hours to obtain 147g / L-221g / L of nicotinic acid or isonicotinic acid. The CGMCC3830 (Pseudomonas putida) has the characteristics of short life cycle, strong vital force, high conversion efficiency, short conversion cycle and the like, the production cost of nicotinic acid or isonicotinic acid is reduced greatly. The production process has the characteristics of mild reaction conditions, low energy consumption and high yield, is environmentally-friendly and the like.

Owner:JIANGNAN UNIV

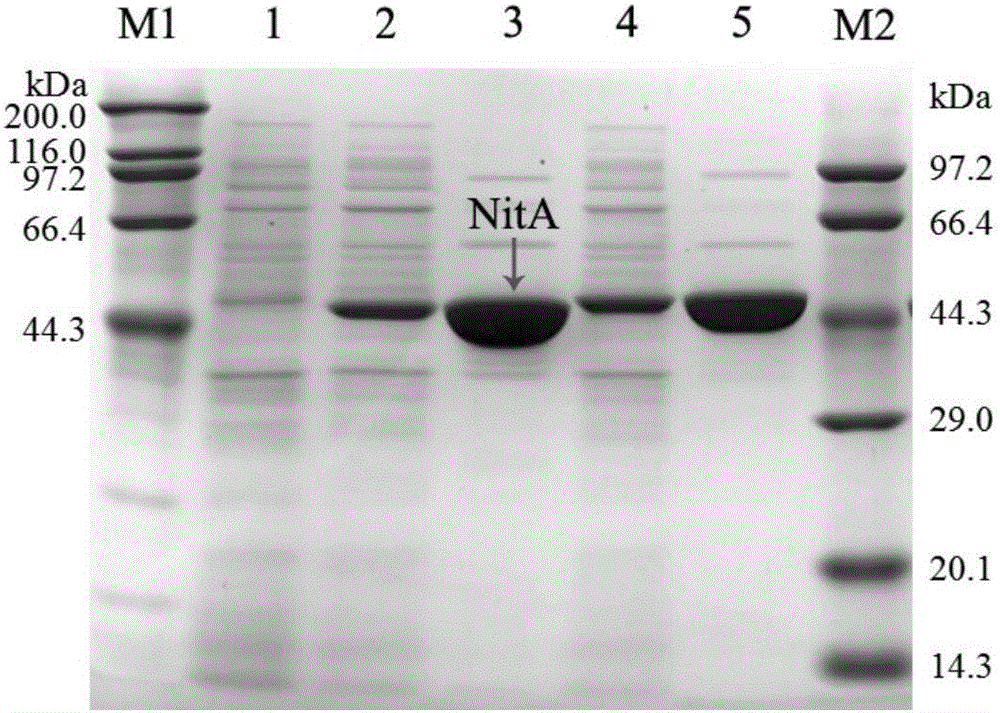

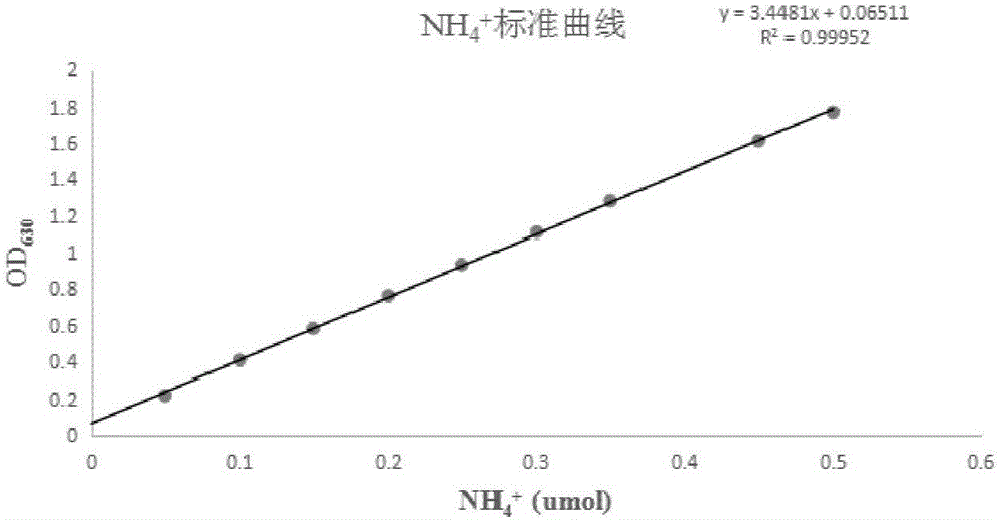

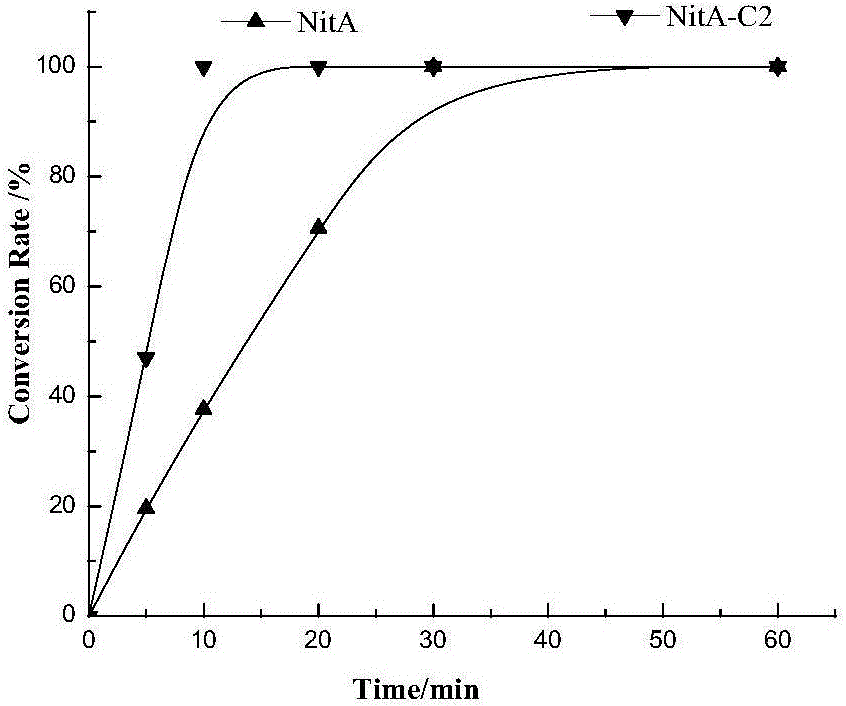

Nitrilase mutant and application thereof in preparation of nicotinic acid

ActiveCN106148310AEfficient productionExpansion of microbial resourcesBacteriaHydrolasesWater bathsBacterial strain

The invention discloses a nitrilase mutant and application thereof in preparation of nicotinic acid. The mutant can be used for mutating phenylalanine at position 168 of an amino acid sequence shown in SEQ ID NO: 2 into valine and serine at position 192 into phenylalanine. A wet cell obtained by induced expression of a recombinant bacterial strain containing an itrilase mutant encoding gene is used as an enzyme source, 3-cyanopyridine is used as a reaction substrate, and a PBS buffer with pH of 7.0 is used as a reaction medium to form a reaction system, a reaction is carried out in a 40 DEG C water bath, and the nicotinic acid is obtained after the reaction is finished.

Owner:NANJING UNIV OF TECH

Feed for feeding broiler

The invention provides feed for feeding a broiler, which comprises basic feed compositions, nicotinic acid, asparaginic acid, methionine, citric acid, malic acid, fish meal, vegetable oil, biotin, amylase, protease, manganese oxide, ferrous sulfate, wine brewing yeast, enterococcus faecium and a Chinese herbal medicine composition additive. The feed provided by the invention has the benefits thatthe immunocompetence of the broiler can be improved, and the probability that the broiler falls ill in the feeding process can be reduced. The feed has no drug residue, so that the survival rate of the broiler is increased.

Owner:孝义新希望六和食品有限公司 +1

Bacillus subtilis for high yield of recombinant nitrilase and application of bacillus subtilis

ActiveCN107254429AImprove security levelReduce manufacturing costBacteriaHydrolasesHydrolase GenePseudomonas putida

The invention discloses bacillus subtilis for high yield of recombinant nitrilase and application of the bacillus subtilis in nicotinic acid synthesis and belongs to the technical field of biological engineering. A method comprises the following steps: performing PCR (polymerase chain reaction) amplification on a Pseudomonas putida CGMCC 3830 nitrilase gene coding sequence, connecting with a pMA5 plasmid, establishing a recombinant plasmid pMat-NIT, and transforming into Bacillus subtilis WB600, thereby obtaining a recombinant bacterium, namely B.subtilis WB600 (pMA5-NIT) which is capable of efficiently expressing nitrilase, wherein the recombinant bacterium is named as Bacillus subtilis NIT-2 and is preserved in the China General Microbiological Culture Collection Center, and the preservation number is CGMCC No.14255. With recombinant bacillus subtilis free cells as a catalyst, 3-cyanopyridine can be completely transformed to generate nicotinic acid. The invention provides a bacillus subtilis strain for high yield of recombinant nitrilase, and the bacillus subtilis strain has outstanding nitrilase activity and is short in recombinant bacterium fermentation period, high in catalysis efficiency and good in application prospect.

Owner:JIANGNAN UNIV

Feed for improving meat quality of meat ducks

The invention provides feed. The feed comprises wheat, bean pulp, fish meal, calcium hydrophosphate, salt, L-carnitine, chromium nicotinate, conjugated linoleic acid, vitamin C and traditional Chinese medicine composition feed additives used for improving the meat quality of meat ducks. The feed has low-toxicity, side-effect-free and residue-free effects and can improve the meat quality of the meat ducks significantly.

Owner:JIANGXI PROVINCE GAOAN CITY LIYUAN FEED CO LTD

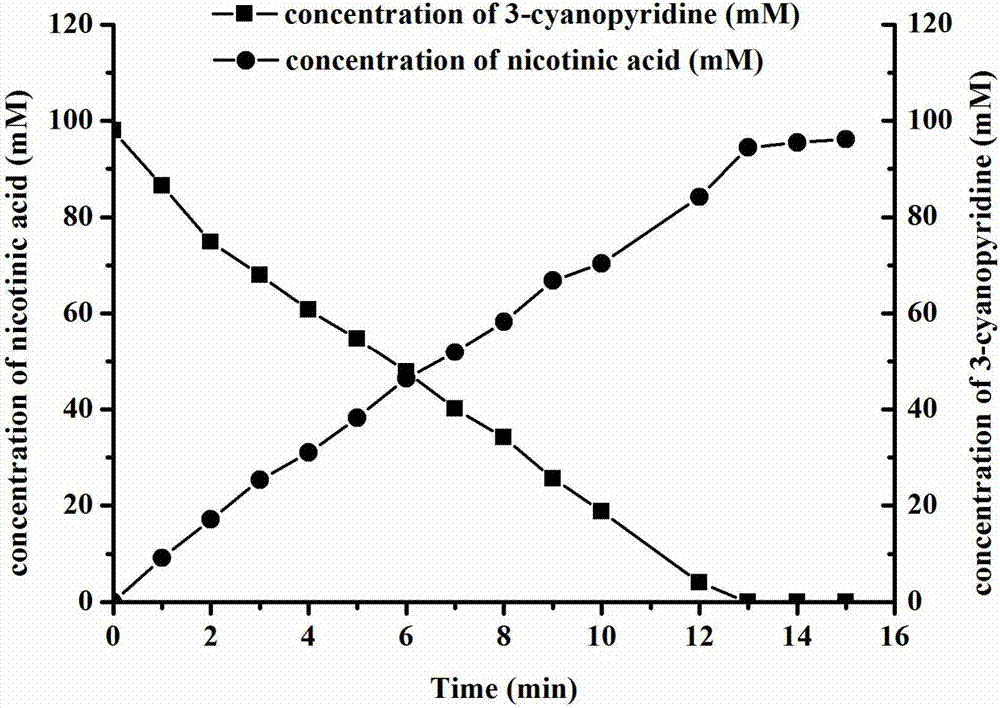

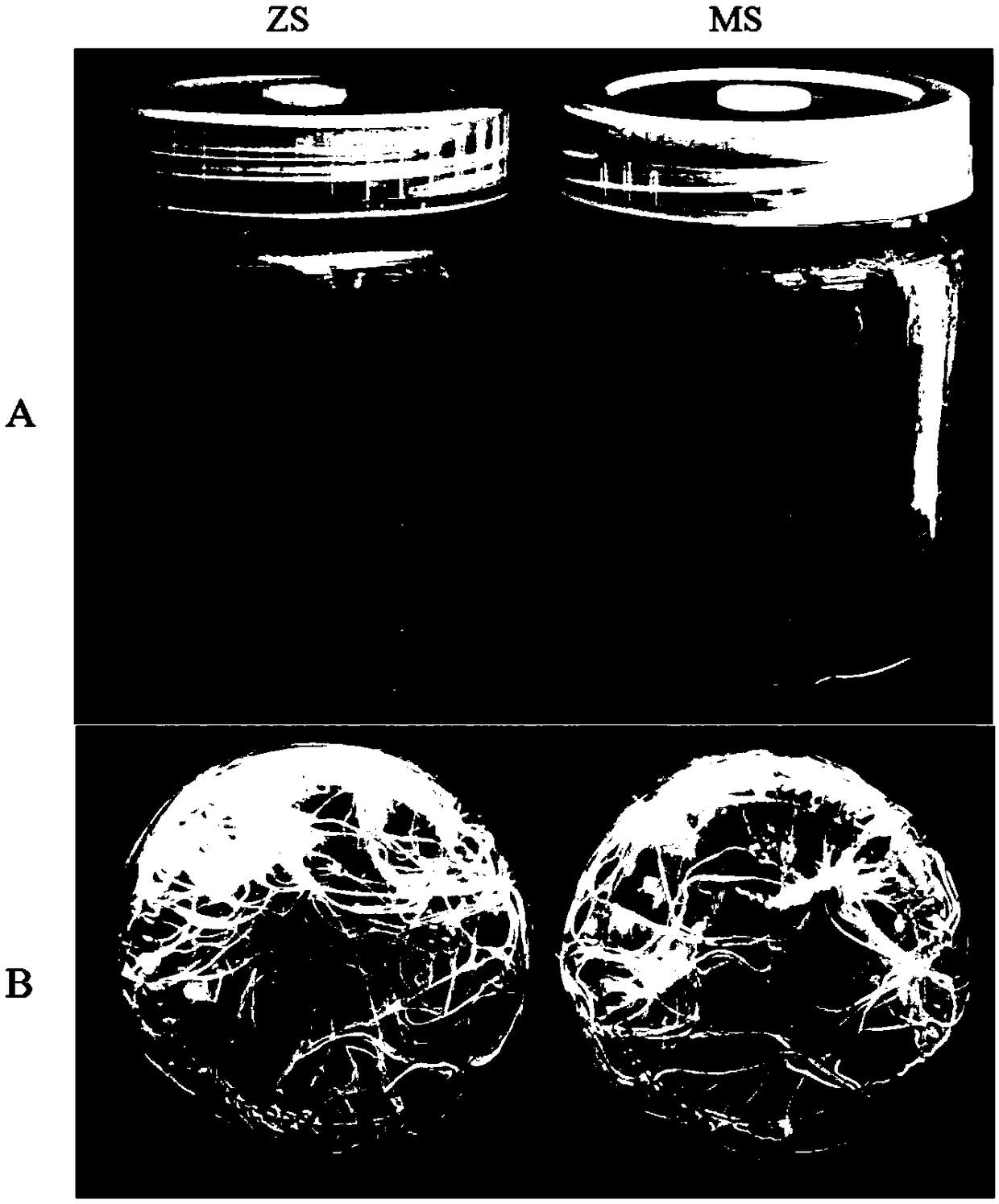

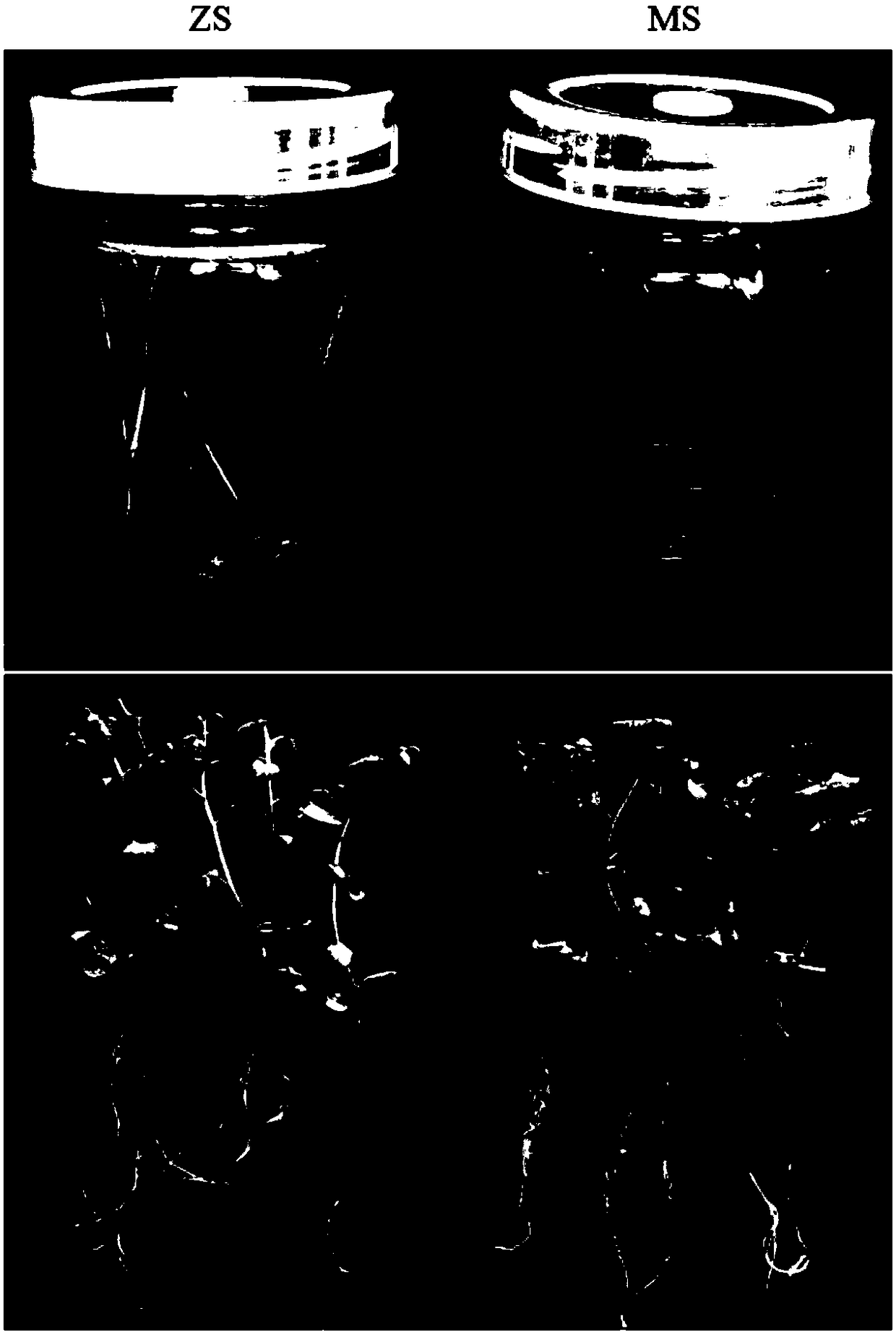

Basic medium for plant tissue culture

ActiveCN108812313AReduce usageImprove securityPlant tissue cultureHorticulture methodsPhosphateThiamine hcl

The invention discloses a basic medium ZS for plant tissue culture and relates to the field of plant propagation. Every 1000 mL of the basic medium ZS contains 3075 mg of potassium nitrate, 578 mg ofammonium phosphate, 491 mg of calcium nitrate, 160 mg of ammonium chloride, 222 mg of magnesium nitrate, 396 mg of ammonium sulfate, 0.83 mg of potassium iodide, 6.2 mg of boric acid, 22.3 mg of manganese sulfate, 8.6 mg of zinc sulfate, 0.25 mg of sodium molybdate, 0.025 mg of copper sulfate, 0.025 mg of cobalt chloride, 100 mg of inositol, 0.1 mg of thiamine hydrochloride (VB1), 0.5 mg of pyridoxine hydrochloride (VB6), 0.5 mg of nicotinic acid, 37.3 mg of ethylenediaminetetraacetic acid disodium salt and 27.8 mg of ferrous sulfate. By means of the basic medium, the same tissue culture effect as an MS medium can be obtained without ammonium nitrate.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

Aluminum alloy two-acid smokeless polishing additive and preparation method thereof

The invention discloses a novel aluminum alloy smokeless two-acid polishing additive and a preparation method thereof. According to the additive, a solution composed of phosphoric acid and pyrophosphoric acid in a certain mass ratio is used as a solvent, sodium molybdate is used as a corrosion inhibitor, copper sulfate and ferric sulfate are used as sensitizers, polyether is used as a dispersing agent, and nicotinic acid is used as a complexing agent. The preparation method comprises the following steps: adding certain amounts of sodium molybdate, copper sulfate, ferric sulfate, nicotinic acid and polyether into the phosphoric acid-pyrophosphoric acid mixture, and dissolving by heating and stirring. The additive does not generate oxynitride yellow smoke or other gaseous pollutants in the traditional three-acid polishing process, thereby preventing the polishing from damaging the human body and environment; and the polishing quality of the additive is comparable with that of the three-acid technique, and thus, the additive is a novel environment-friendly high-efficiency aluminum alloy two-acid polishing additive.

Owner:WENGFU (GRP) CO LTD

Culture medium for phalaenopsis amabilis tissue culture

The invention provides a culture medium for phalaenopsis amabilis tissue culture. The culture medium comprises the following components: 1900 mg / L of KNO3; 1650 mg / L of ammonium nitrate; 170 mg / L of potassium dihydrogen phosphate; 370 mg / L of magnesium sulfate heptahydrate; 440 mg / L of calcium chloride dihydrate; 0.60-0.62 mg / L of KI; 4.5-4.8 mg / L of boric acid; 25.0-25.3 mg / L of manganese sulfate tetrahydrate; 7.0-7.2 mg / L of zinc sulfate heptahydrate; 0.20-0.22 mg / L of sodium molybdate dihydrate; 0.025 mg / L of copper sulfate pentahydrate; 0.025 mg / L of cobalt chloride hexahydrate; 37.25 mg / L of Na2.EDTA; 27.85 mg / L of ferrous sulfate heptahydrate; 100 mg / L of inositol; 2 mg / L of glycine; 0.1 mg / L of thiamine hydrochloride; 0.5 mg / L of pyridoxine hydrochloride; 0.5 mg / L of nicotinic acid; 20-22 g / L of sucrose; 5-5.2 g / L of agar; 30-35 g / L of a banana juice; 3-5 g / L of a pear juice; 0.45-0.48 g / L of activated carbon; and a solvent being deionized water. With application of the culture medium to culture phalaenopsis amabilis, the survival rate is more than 96%, the bacteria infection rate is 2.7-2.8%, and the browning degree of the culture medium is 30-40% lower than that of an MS culture medium.

Owner:柳州赛特生物科技研发中心

Electronic cigarette liquid, preparation method thereof and novel acid for preparing nicotine salt and electronic cigarette

The invention relates to an electronic cigarette liquid, a preparation method thereof and a novel acid for preparing a nicotine salt and an electronic cigarette. The electronic cigarette is prepared from the following raw materials in parts by weight: 1 to 5 parts of nicotine, 2 to 10 parts of organic acid and 50 to 300 parts of organic solvent, wherein the organic acid is any one or a mixture ofnicotinic acid, parafluorobenzoic acid and para aminobenzoic acid. The electronic cigarette is prepared through reaction of the nicotine and a specific type of organic acid in the organic solvent. Compared with other existing electronic cigarette liquids, the electronic cigarette liquid disclosed by the invention has the advantages of lower nicotine salt concentration (the content of the nicotineis lower than or equal to 20mg / mL), better smoking feel, unique atomizing effect and smoking feel, and certain health care function.

Owner:深圳多客技术有限公司

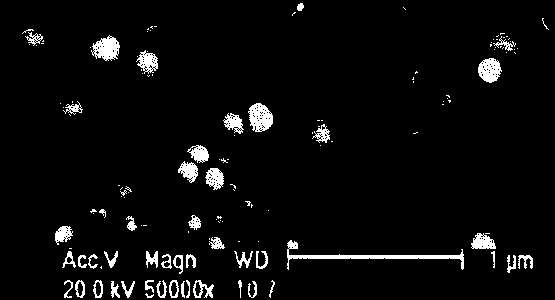

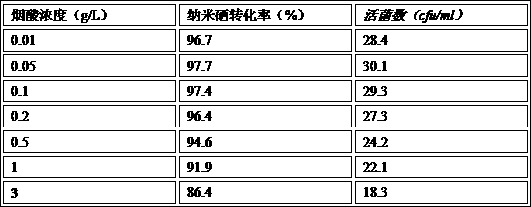

Photosynthetic bacterium with high yield nano-selenium and preparation method of nano-selenium living bacterium preparation thereof

PendingCN110964674AImprove conversion rateLower conversion rateBiocidePlant growth regulatorsBiotechnologyHigh concentration

The invention discloses a photosynthetic bacterium with high yield nano-selenium and a preparation method of a nano-selenium living bacterium preparation thereof. The invention particularly disclosesthiocapsa roseopersicina capable of tolerating high-concentration (25g / L) sodium selenite. Nicotinic acid is creatively used for modifying high-concentration biological nano-selenium, so that the storage stability of the nano-selenium in the liquid is greatly improved. Meanwhile, the conversion rate of the nano-selenium is over 90 and thus nano-selenium fermentation liquid can be not subjected tocentrifugal purification, so that a liquid nano-selenium preparation which is relatively high in nano-selenium content, contains viable bacteria and is long in preservation time can be directly obtained. Problems that high-concentration biological nano-selenium prepared by the microorganisms in the prior art can not be stored in a liquid mode and easy transformation to black elemental selenium occurs frequently are solved and defects of high energy consumption and serious pollution are overcome. The nano-selenium living bacterium preparation has advantages of simple production process, low cost, low equipment requirement, no emission of three wastes, and environmental friendliness has the great market popularization value.

Owner:FOSHAN YANHUI BIOTECH CO LTD

Beef cattle heat stress resisting feed additive and using method thereof

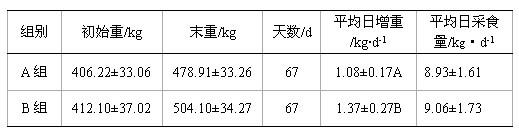

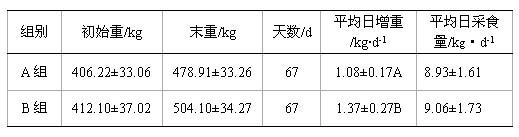

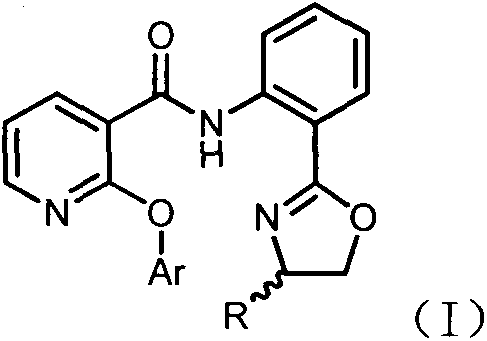

The invention discloses a beef cattle heat stress resisting feed additive and a using method thereof. The beef cattle heat stress resisting feed additive comprises the following components in parts by weight: 5-15 parts of chromium nicotinate and 985-995 g of diluents. A test result of the beef cattle heat stress resisting feed additive is showed in a high-temperature environment; and the average daily weight gain, the average daily feed intake and the economic benefit of a chromium nicotinate group are respectively increased by 26.85%(p<0.01), 1.46% and 89.32% compared with a control group.

Owner:HENAN AGRICULTURAL UNIVERSITY

Compound yak blocks for balancing minerals in warm seasons and preparation process thereof

InactiveCN102669430AAchieving Balanced SupplyChoose from a wide range of sourcesAnimal feeding stuffSodium BentoniteBrick

The invention discloses compound yak blocks for balancing minerals in warm seasons. Each kg of blocks are formed by the following raw materials: 0.3-0..9g of zinc sulfate, 0.3-0.6g of copper sulfate, 0.01-0.02g of sodium selenite, 0.07-0.2g of potassium iodide, 0.04-0.08g of cobalt chloride, 20-40g of magnesium oxide, 3-6g of chromium nicotinate, 50-100g of calcium hydrophosphate, 300-500g of salt, 200-400g of bentonite, 30-60g of cement, 20-100g of limestone and 30-60g of molasses. The invention simultaneously provides a preparation process of the compound yak blocks. The blocks and the preparation process have the following advantages: according to the seasonal characteristics of yak production and seasonal variations of contents and compositions of mineral elements in grass, in combination with compositions and quantities of mineral elements in soil ingested by the yaks, the yak block mineral formula is optimized in real time to realize balanced supply of the mineral elements to the yaks; the chemocoagulation process and the mechanical compaction process are optimally combined; and the products have high density and reasonable feed intake and are suitable for yak mineral element supply in warm seasons.

Owner:NINGXIA UNIVERSITY

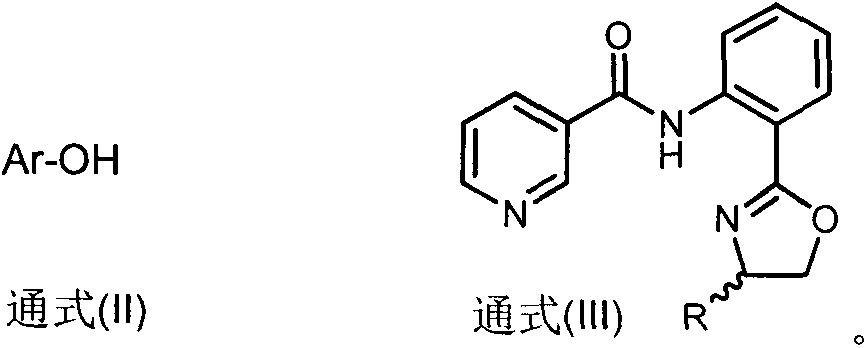

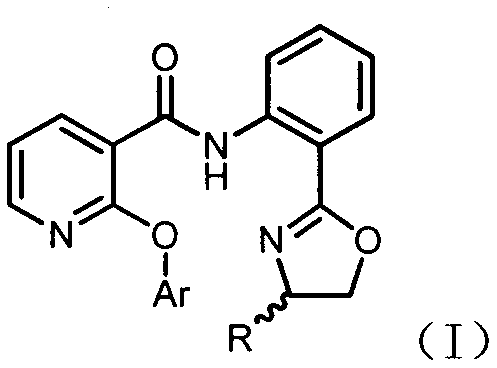

Novel 2-aryloxynicotinamide compound, and preparation method and application of same

InactiveCN110872283AImprove herbicidal activityReaction raw materials are readily availableBiocideOrganic chemistryArylCombinatorial chemistry

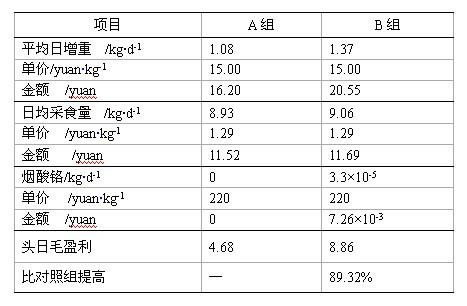

The invention relates to a novel 2-aryloxynicotinamide compound, and a preparation method and an application of same, wherein the 2-aryloxynicotinamide compound has a chemical structural formula as the formula (I). With nicotinic acid being initial raw material, the compound is prepared through a condensation reaction and a carbon-hydrogen bond direct etherification. The invention can provide a new method for preparing the 2-aryloxynicotinamide compounds and derivatives thereof, which can be used for preparing an herbicide, diflufenican. The compounds show excellent herbicidal activity and have a potential as an herbicide applied to agricultural-related fields. In the general formula (I), the carbon atom connected to the substitution group R has a spatial configuration of R or S, Ar representing an aryl substitution group (detailed in the specification).

Owner:NANJING AGRICULTURAL UNIVERSITY

Broadleaf holly leaf buccal tablet capable of reducing high blood pressure, high blood lipid and high blood glucose and production method of buccal tablet

InactiveCN104474472ANo side effectsNo bad smellNervous disorderHydroxy compound active ingredientsBiotechnologyMenthol

The invention discloses a broadleaf holly leaf buccal tablet capable of reducing high blood pressure, high blood lipid and high blood glucose and a production method of the buccal tablet. The broadleaf holly leaf buccal tablet is characterized being prepared from the following raw materials in parts by weight: 90-100 parts of broadleaf holly leaves, 20-30 parts of momordica grosvenori, 8-12 parts of radix polygonati officinalis, 8-12 parts of rhinacanthus nasutus, 4-8 parts of persimmon leaves, 3-5 parts of radix curcumae longae, 3-5 parts of kelp, 1-2 parts of catharanthus roseus, 1-2 parts of nicotinic acid, 1-2 parts of menthol, 50-70 parts of filler and 10-15 parts of a lubricant. The broadleaf holly leaf buccal tablet capable of reducing high blood pressure, high blood lipid and high blood glucose has the characteristics of reducing high blood pressure, high blood lipid and high blood glucose, clearing away heat and toxic materials, tonifying spleen, calming nerves, losing weight, inhibiting and preventing cancer and the like.

Owner:DAXIN SCI & TECH INFORMATION RES INST

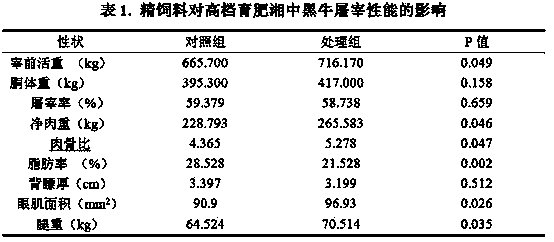

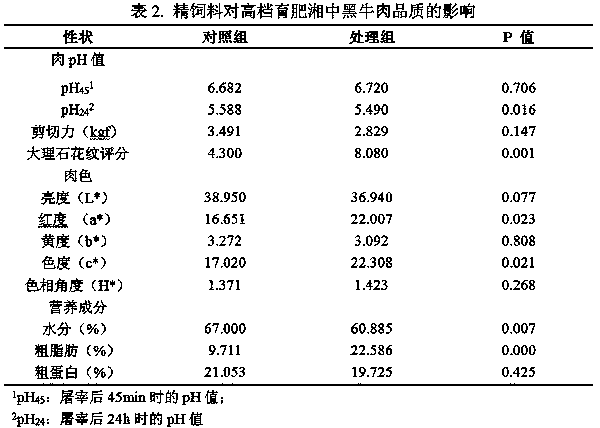

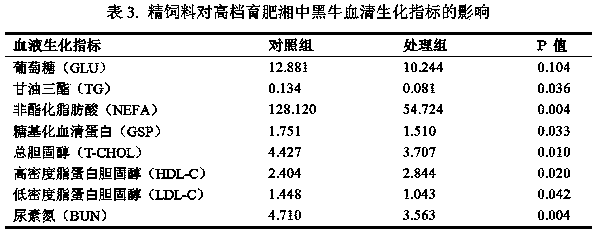

Fine fodder capable of improving content of intramuscular fat and meat quality of beef and preparation and using methods thereof

InactiveCN104171504AImprove rednessIncrease brightnessAnimal feeding stuffBiotechnologyIntramuscular fat

The invention discloses a fine fodder capable of improving the content of intramuscular fat and the meat quality of beef. The fine fodder per kilogram contains 500mg-1500mg of nicotinic acid. The invention further provides a preparation method and a using method of the fine fodder capable of improving the content of intramuscular fat and the meat quality of beef. The fine fodder disclosed by the invention can significantly improve the marble score of longissimus dorsi muscle of beef cattle by 3.7, very significantly improve the content of intramuscular fat of beef cattle and also significantly improve the live weight before slaughter, net meat weight, meat-bone ratio, leg weight and eye muscle area of the beef cattle and the redness (a*) and brightness (L*) of beef without adverse effects on back fat thickness. The fine fodder disclosed by the invention is suitable for feeding of castrated beef cattle in the fattening period, is used for producing high-grade beef and has the characteristics that the feeding with the fine fodder is simple to operate, the fodder can be applied into production conveniently and can significantly improve economic and social benefits of beef cattle breeding industry, etc.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

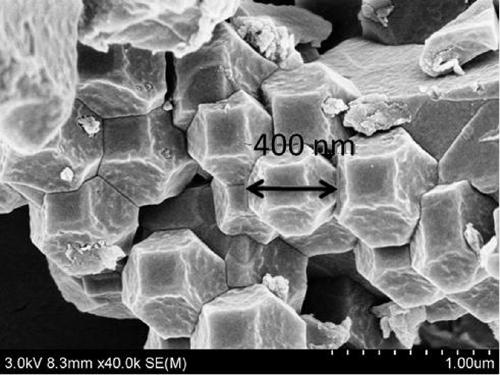

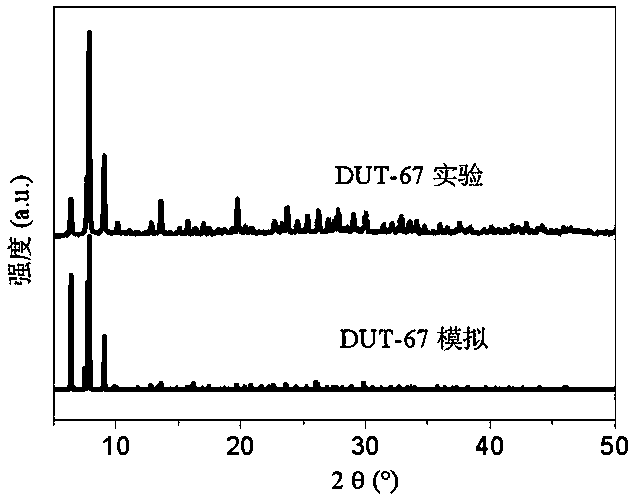

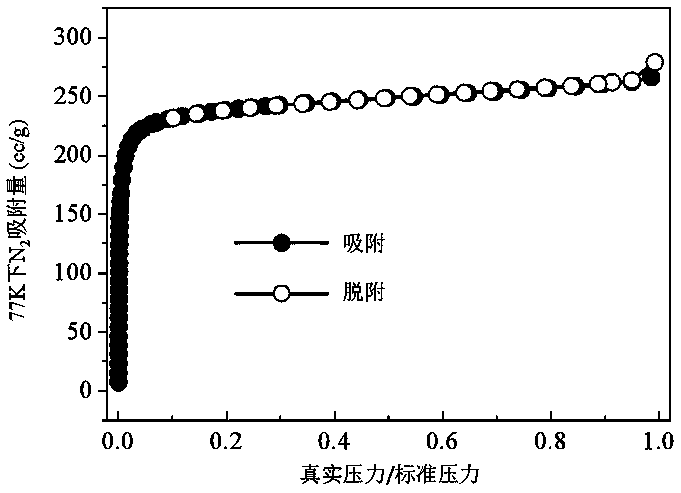

Preparation method and application of zirconium based metal-organic frameworks

ActiveCN110339816AUnique binding siteAbundant μ-OH sitesOrganic chemistryOther chemical processesNiacinamideBinding site

Belonging to the technical field of adsorption separation of nicotinamide and nicotinic acid, the invention provides a preparation method and application of zirconium based metal-organic frameworks, and solves the technical problem of difficult adsorption separation of nicotinamide and nicotinic acid by existing conventional separation method. The zirconium based metal-organic frameworks DUT-67 disclosed by the invention is synthesized by solvothermal method, the chemical formula of the zirconium based metal-organic frameworks DUT-67 is Zr6O6(OH)2(tdc)4.3.1H2O.0.6DMF, with certain pore structure and unique binding site, the zirconium based metal-organic frameworks DUT-67 can achieve rapid selective adsorption separation of nicotinamide and nicotinic acid, the separation effect is obvious and the operation process is simple, the utilization rate of nicotinamide and nicotinic acid can be effectively enhanced, and the economic benefits can be improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

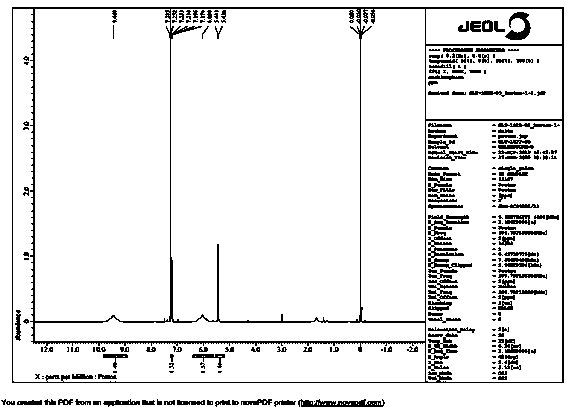

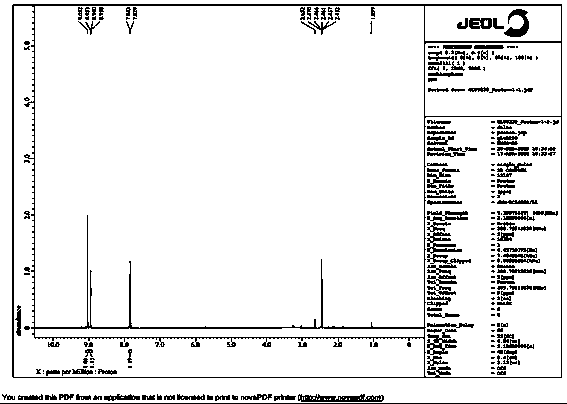

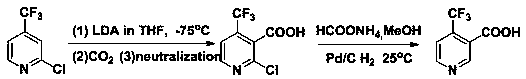

Preparation method of 4-trifluoromethyl nicotinic acid

ActiveCN111574440AEasy to operateMild conditionsOrganic chemistryChemical recyclingMeth-Propanoic acid

The invention relates to a synthetic method of 4-trifluoromethyl nicotinic acid. The method is characterized by comprising the following steps: (1) in a solvent A, enabling methyl acrylate to react for 30-60 minutes at 25-90 DEG C under the action of a catalyst and an oxidizing agent, with the molar ratio of methyl acrylate to the catalyst to the oxidizing agent being 1:(0.01-0.05):(1-1.5), so asto prepare methyl 3-oxopropionate; (2) in a solvent B, controlling the mole ratio of the methyl 3-oxopropionate to 4-amino-1,1,1-trifluoro-3-buten-2-one to be (1-1.5):1, reacting at 25-90 DEG C for 30-60 min to prepare N-(2-methoxycarbonyl vinyl)-4,4,4-trifluoro-3-one-1-butenylamine, then adding an alkali, with the mole ratio of the N-(2-methoxycarbonyl vinyl)-4,4,4-trifluoro-3-one-1-butenylamineto the alkali being 1:1-5, performing ring closing hydrolysis at 25-90 DEG C under the action of the alkali for 30-60 min, subjecting the reaction product to rectification separation after the reaction is finished to obtain a 4-trifluoromethyl nicotinic acid finished product. The method has the advantages that the adopted raw materials are cheap and easy to obtain, the synthesis method is simple to operate, reaction conditions are mild, requirements on equipment are low, and the method is suitable for industrial large-scale production.

Owner:ANHUI JINGHE IND

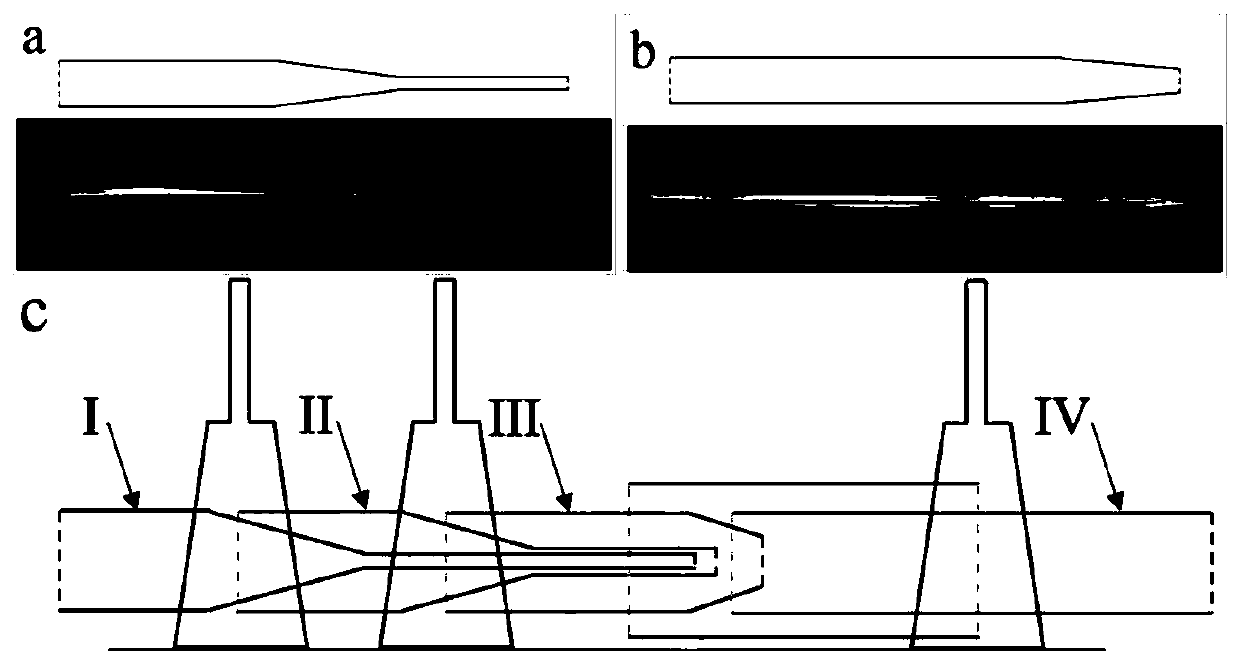

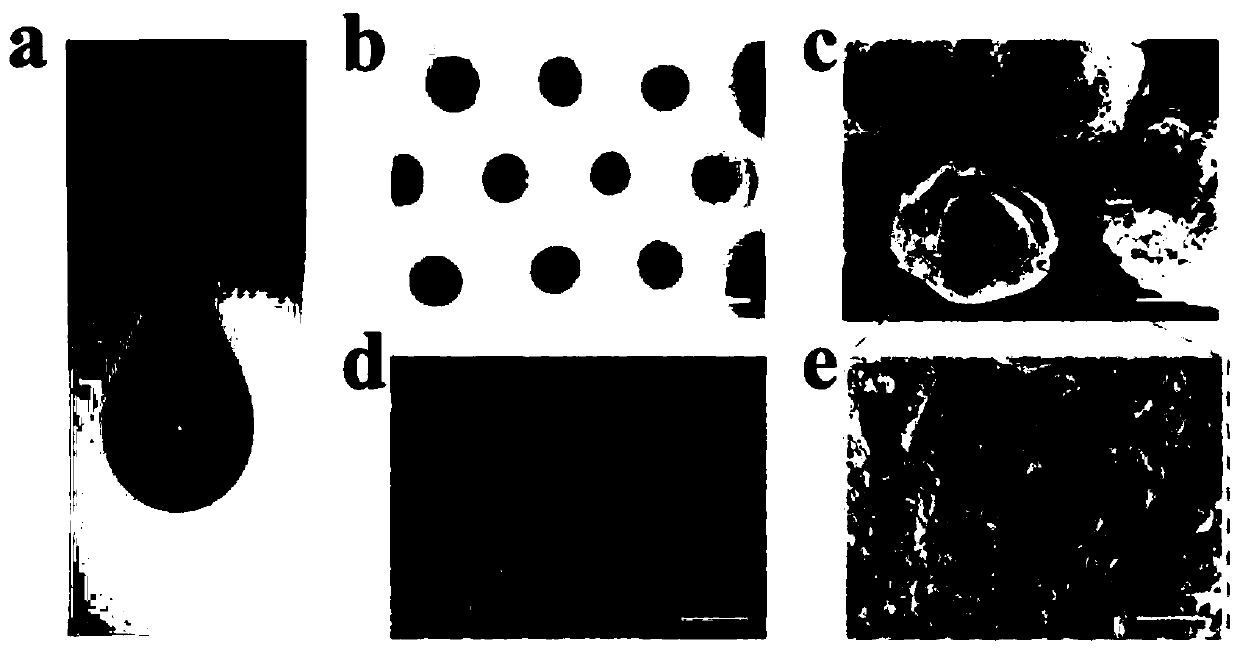

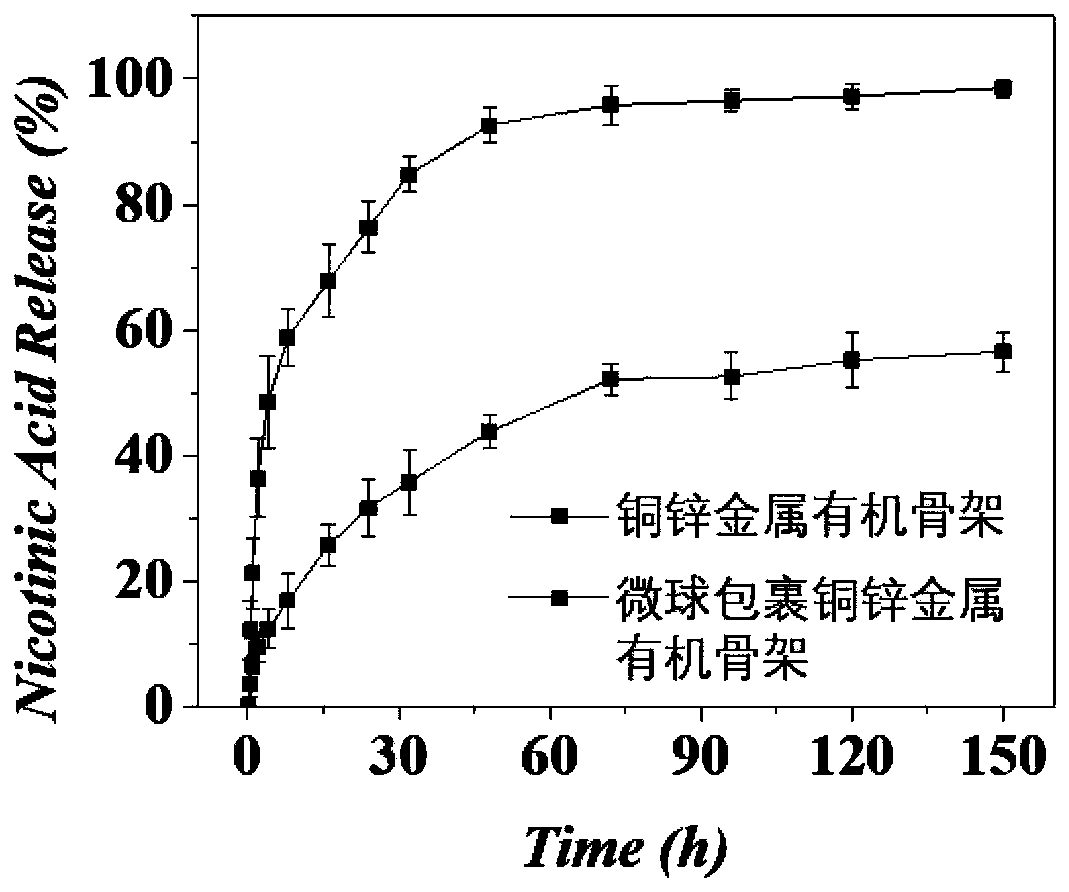

Hydrogel microcapsule for encapsulating nicotinic acid metal organic framework and preparation method and application thereof

InactiveCN111000863AReduce releaseImprove antibacterial propertiesOrganic active ingredientsInorganic active ingredientsAcetic acidControl release

The invention discloses a hydrogel microcapsule for encapsulating a nicotinic acid metal organic framework and a preparation method and application thereof. The preparation method of the hydrogel microcapsule for encapsulating the nicotinic acid metal organic framework comprises the steps that a nicotinic acid solution is used as an inner phase 1; a mixed solution of a zinc acetate solution and acopper acetate solution is used as an inner phase 2; a sodium alginate solution is used as an outer phase; and a microfluidic device is used for spraying mixed liquid drops of the inner phase 1 and the inner phase 2 wrapped by the outer phase into a calcium chloride solution to prepare the hydrogel microcapsule for encapsulating the nicotinic acid metal organic framework. The hydrogel microcapsulefor encapsulating the nicotinic acid metal organic framework, which is prepared by the invention, has ideal controlled release effect, antibacterial effect and anti-oxidative stress effect, and can be used for preparing wound healing materials or medical instruments.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

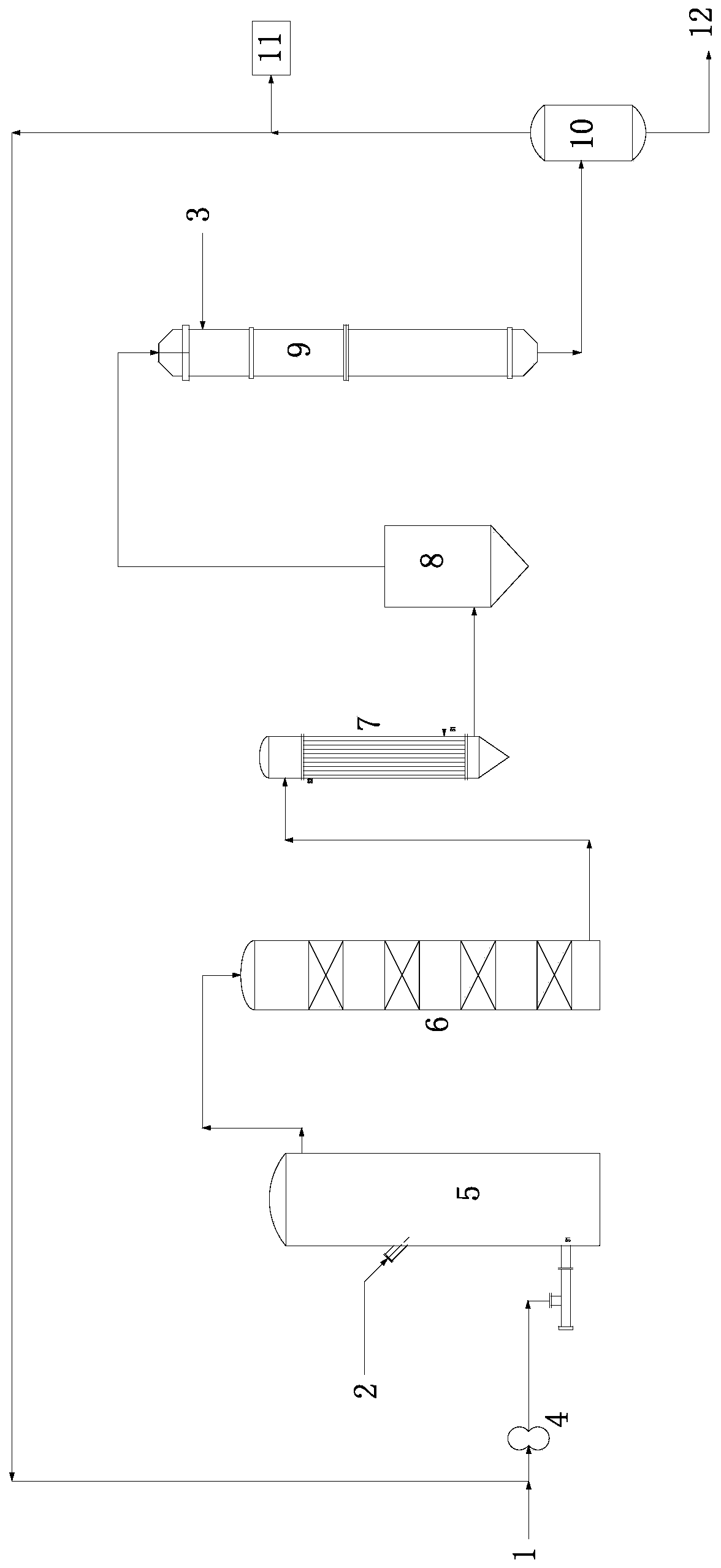

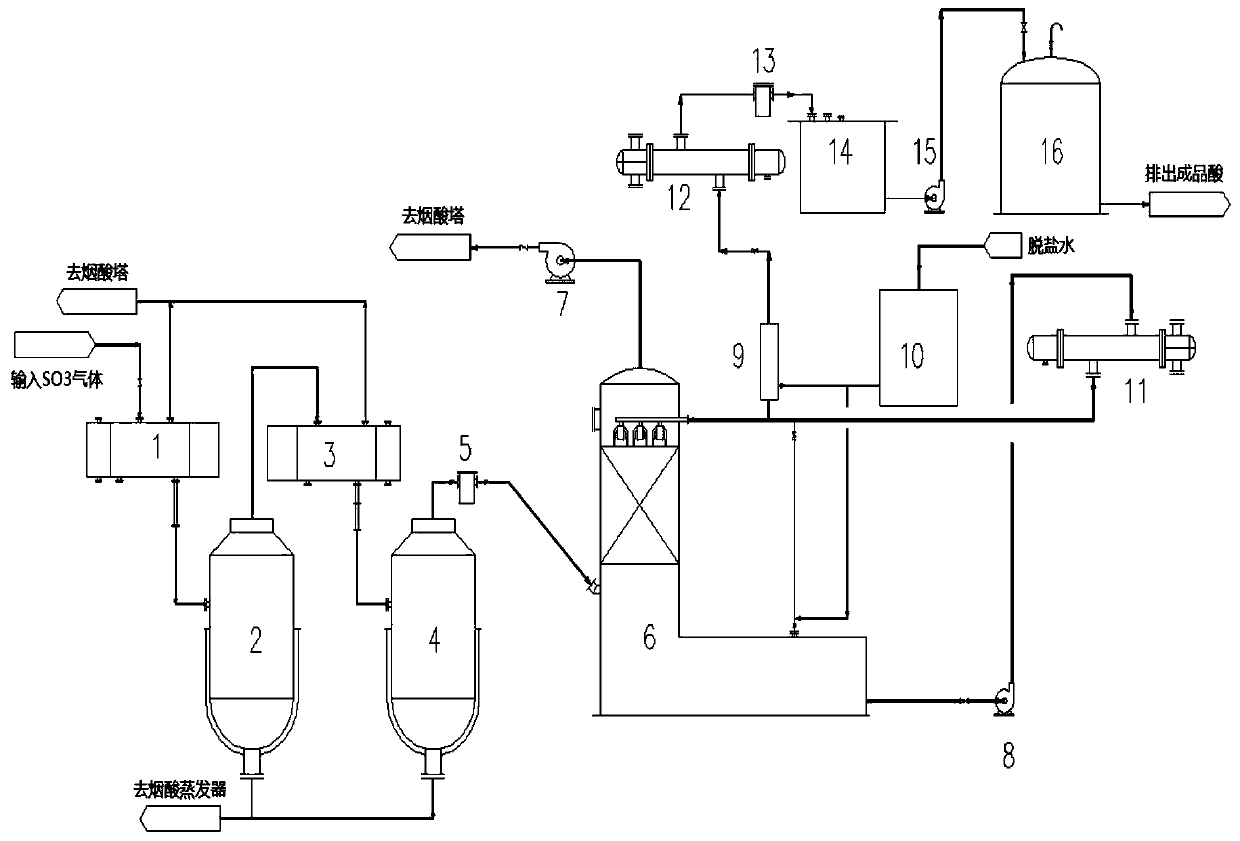

Gas-phase SO3 sulfonation process and production system

InactiveCN111039830ABenign environmental effectNo emissionsCombination devicesSulfonic acids salts preparationCombustionExhaust gas emissions

The invention belongs to the technical field of fine chemical engineering. The invention aims to provide a gas-phase SO3 sulfonation process and a production system thereof. The sulfonation system basically has no exhaust emission and good environmental effect, and meanwhile, dangerous solid wastes such as electrostatic acid and the like are not generated any more. According to a technical schemein the invention, the gas-phase SO3 sulfonation process comprises the following steps: 1) mixing tail gas having undergone gas-liquid separation after sulfonation with a certain flow of oxygen, conveying the obtained mixture into a sulfur burning furnace from a gas-phase inlet of the sulfur burning furnace through a Roots blower, and enabling liquid sulfur to enter the sulfur burning furnace froma liquid sulfur inlet of the sulfur burning furnace, and carrying out contact combustion in the sulfur burning furnace to generate SO2 gas; 2) subjecting the SO2 gas to conversion by a conversion tower, cooling by a cooler and filtering by an SO3 filter to remove a trace amount of nicotinic acid so as to obtain SO3 gas, and allowing the SO3 gas to enter a sulfonator and to contact with an organicmaterial input into the sulfonator from another inlet for a sulfonation reaction; and 3) subjecting a sulfonation product to gas-liquid separation, and recycling a gas phase to the step 1).

Owner:ZANYU TECH GRP CO LTD +1

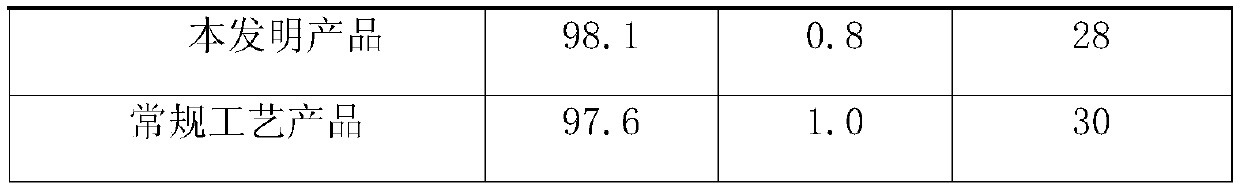

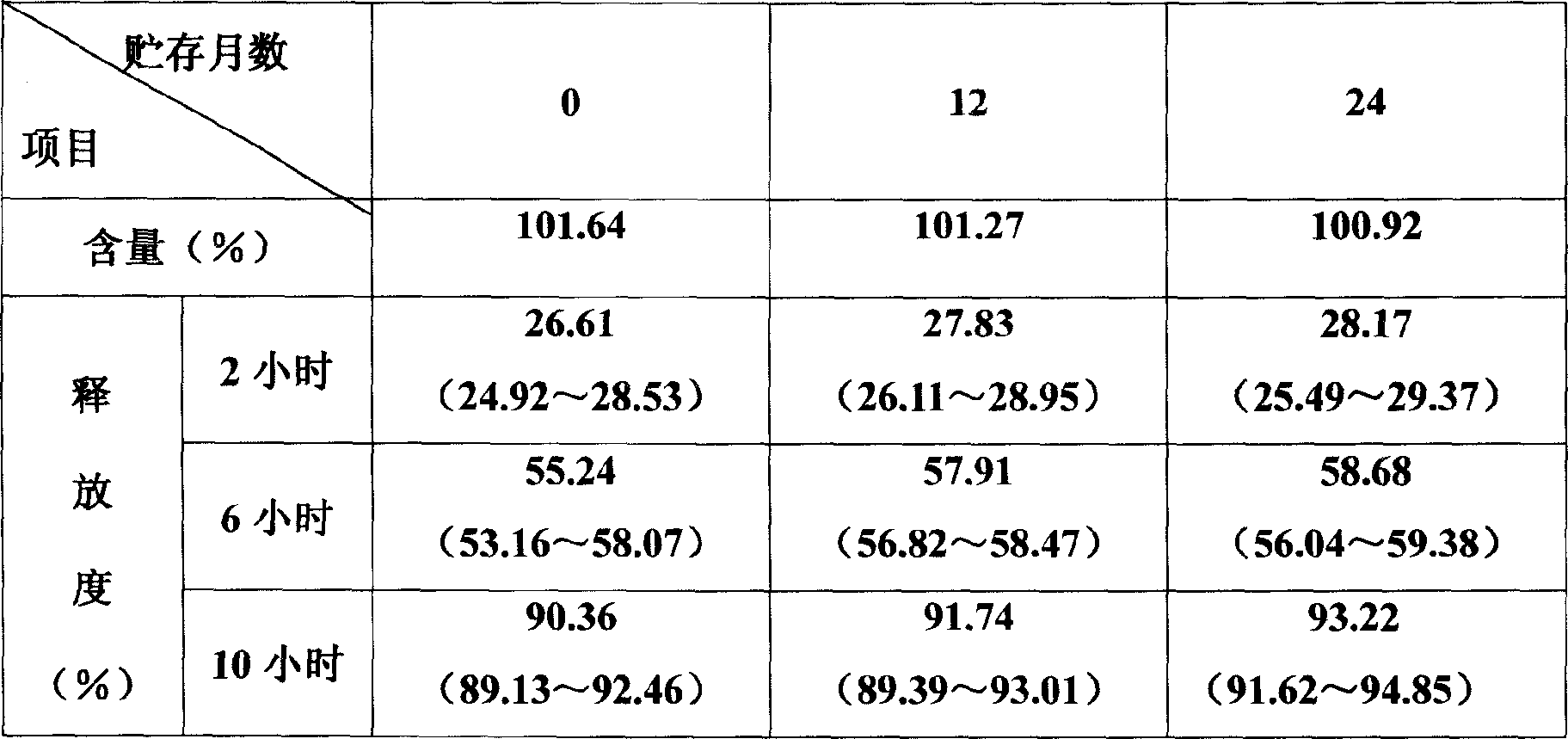

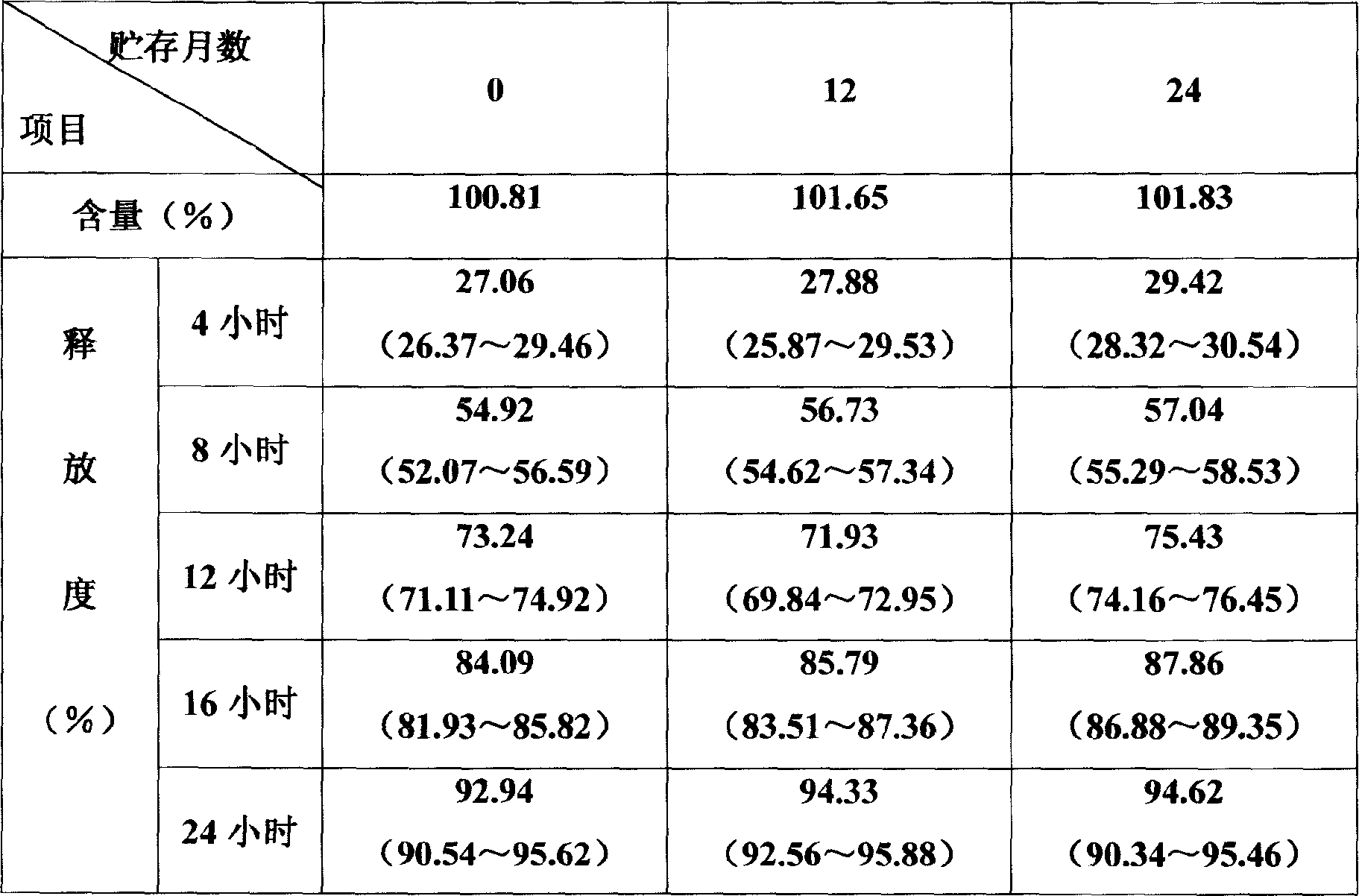

Nicotinic acid controlled releasing tablet and preparation method thereof

The invention relates to a nicotinic acid controlled releasing tablet which comprises core constituents and film control release coating constituents, the preparing process consists of mixing prescription amount of nicotinic acid with core constituents, tabletting into cores, then preparing coating liquid from the film control release coating constituents, finally loading the prepared cores into a coating pan, and coating with coating liquids.

Owner:山东特瑞林医药科技发展有限公司

Proliferation culture medium for tissue culture of Jietu vaccinium vitisidaea

ActiveCN103875532AFew ingredientsShorten the growth cyclePlant tissue cultureHorticulture methodsBiotechnologySucrose

The invention discloses a proliferation culture medium for tissue culture of Jietu vaccinium vitisidaea. The proliferation culture medium comprises an improved WPM (woody plant medium), 2mg / L zeatin, 30g / L sucrose and 8g / L agar; the pH value is 4.8-5.0; each liter of improved WPM comprises a large quantity of elements including 1071.6mg of potassium nitrate, 370mg of magnesium sulfate, 96mg of calcium chloride and 170mg of potassium dihydrogen phosphate, ferric salts including 37.3mg of ethylene diamine tetraacetic acid and 27.8mg of ferrous sulfate, microelements including 22.3mg of manganese sulfate, 8.6mg of zinc sulfate, 0.025mg of copper sulfate, 0.25mg of sodium molybdate and 6.2mg of boric acid, and organic matters including 0.5mg of nicotinic acid, 0.5mg of thiamine hydrochloride, 0.5mg of pyridoxine hydrochloride, 100mg of inositol and 2mg of glycine. According to the culture medium, the proliferation rate reaches 9.8 after 30 days.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

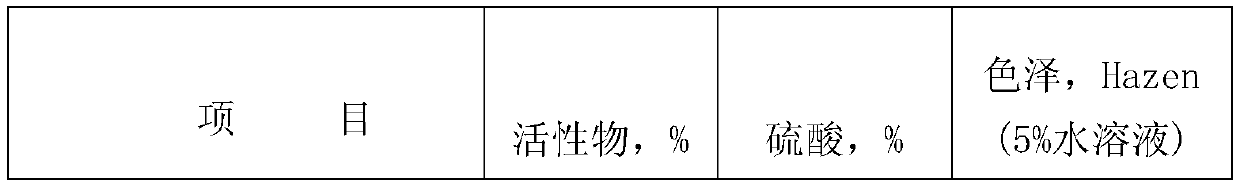

Production device and production process of EL-grade sulfuric acid

PendingCN111533091AReduce energy consumptionIncrease elasticityChemical industrySulfur-trioxide/sulfuric-acidProcess engineeringSulfur trioxide

The invention relates to a production device of EL-grade sulfuric acid. The production device comprises a first condenser, a second condenser, a first gasifier and a second gasifier which are connected in sequence. The first condenser is communicated with a falling film evaporator in the nicotinic acid evaporation process and is used for receiving evaporated sulfur trioxide gas; the second gasifier is connected with an EL-grade sulfuric acid absorption tower, the EL-grade sulfuric acid absorption tower is tower-tank integrated equipment and comprises an absorption tower body and an acid tank,the acid tank is connected with a circulating acid cooler through a circulating acid pump, and the outlet of the circulating acid cooler is divided into three paths which are respectively communicatedwith the acid tank, the absorption tower body and a diluter; the diluter is communicated with the water treatment device and is used for receiving high-purity water; the diluter is communicated withthe finished product acid cooler and is used for cooling to prepare finished product acid. The production device has the advantages of low energy consumption and no pollution. The invention also provides a production process of EL-grade sulfuric acid.

Owner:上海六谦工程科技股份有限公司

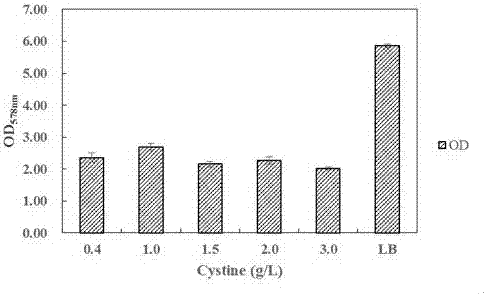

Synthetic medium for Staphylococcus carnosus, and preparation method and application of Staphylococcus carnosus fermentation broth

ActiveCN107502620ASuitable for growthSuitable for secretory needsPolypeptide with localisation/targeting motifBacteriaDipotassium hydrogen phosphateArginine

The invention discloses a synthetic medium for Staphylococcus carnosus, and a preparation method and application of Staphylococcus carnosus fermentation broth. The synthetic medium for Staphylococcus carnosus comprises the following raw materials by weight: on the basis of a volume of 1 L, 10 to 50 g of anhydrous glucose, 0.1 to 1.5 g of lysine, 1.0 to 5.0 g of valine, 0.1 to 1.5 g of glycine, 1.0 to 5.0 g of arginine, 1.0 to 5.0 g of proline, 5 to 10.0 g of glutamic acid, 0.1 to 0.5 g of tryptophan, 0.1 to 1.5 g if cystine, 1.0 to 3.0 mg of thiamine hydrochloride, 1.0 to 3.0 mg of calcium pantothenate, 1.0 to 3.0 mg of nicotinic acid, 1.0 to 3.0 mg of manganese sulfate, 0.1 to 1.0 g of potassium dihydrogen phosphate, 0.1 to 0.8 g of magnesium sulfate heptahydrate, 0.005 to 0.010 g of ferrous sulfate heptahydrate, 1.0 to 5.0 g of dipotassium hydrogen phosphate trihydrate and 6 to 10 g of 3-(N-morpholino)propanesulfonic acid, with the balance being water. The invention also discloses a preparation method for the Staphylococcus aureus fermentation broth. The synthetic medium for Staphylococcus carnosus is reasonable in composition, rich in nutrients and capable of meeting the growth demands of Staphylococcus carnosus. The growth amount of Staphylococcus carnosus obtained through the synthetic medium provided by the invention is increased by 5% compared with the growth amount of Staphylococcus carnosus obtained through frequently used LB (Luria-Bertani) mediums.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of high purity nicotinamide and nicotinic acid

The invention provides a preparation method of high purity nicotinamide and nicotinic acid. In an ethanol and water system and in the presence of NaOH and MnO2, 3-cyanopyridine hydrolyzes to obtain high content of nicotinamide and nicotinic acid by adjusting the ratio of ethanol and water. When ethanol and water are in the weight ratio of 19:1, 3-cyanopyridine hydrolyzes to obtain is 99.5% of nicotinamide, and the yield is higher than 95%; and when the ethanol and water are in the weight ratio of 1:9, the 3-cyanopyridine hydrolyzes to obtain 99.5% of nicotinic acid, and the yield is more than 95%. The method has the characteristics of mild reaction conditions, high product purity and high yield; and only by adjusting the content of ethanol, high purity nicotinamide and nicotinic acid are obtained. At the same time, the method has less waste and less pollution, and is beneficial for industrialized production.

Owner:ANHUI COSTAR BIOCHEM CO LTD

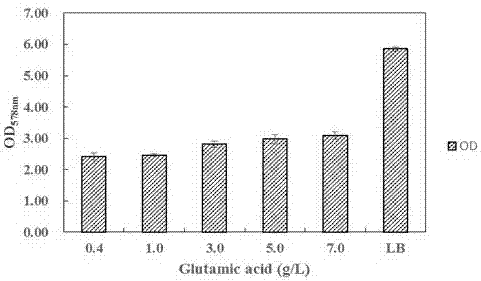

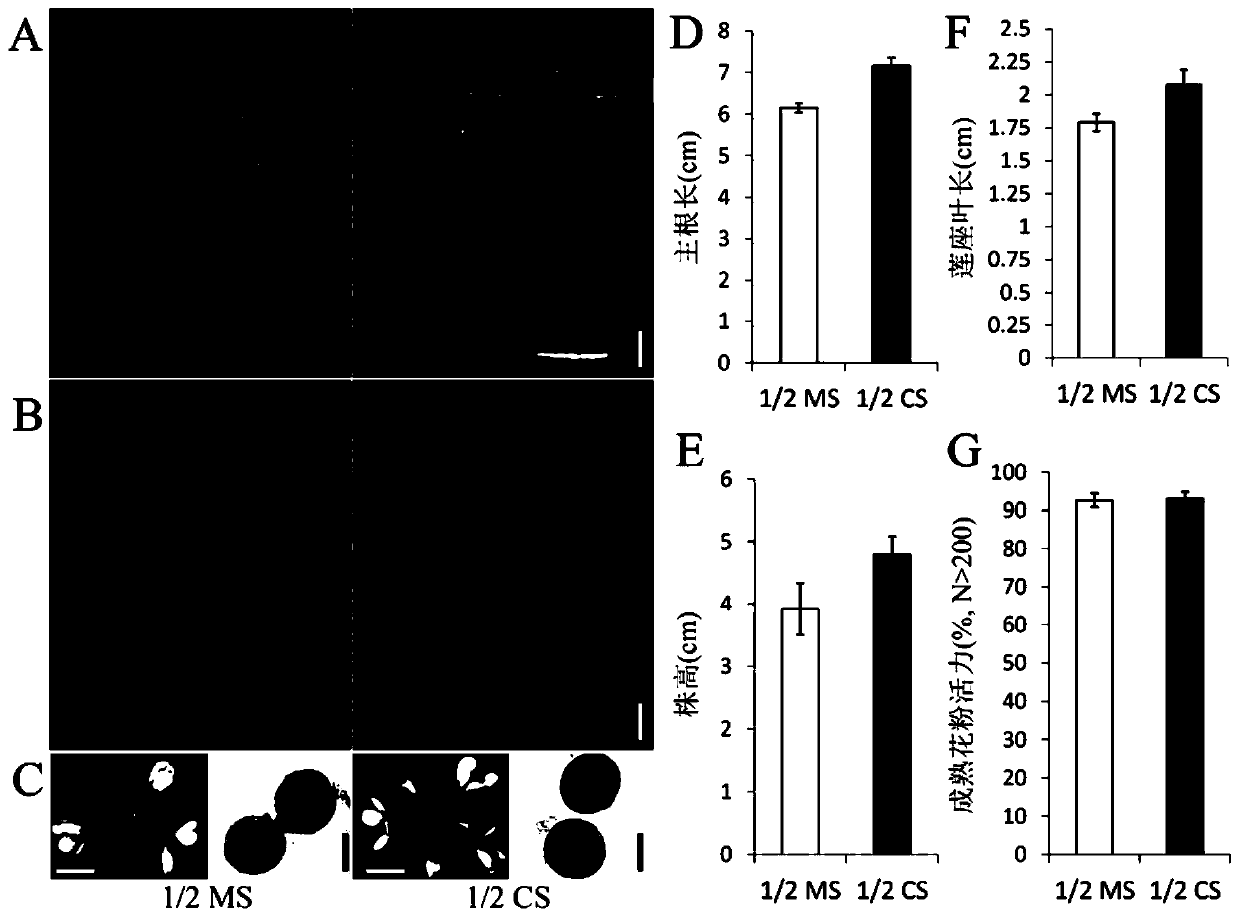

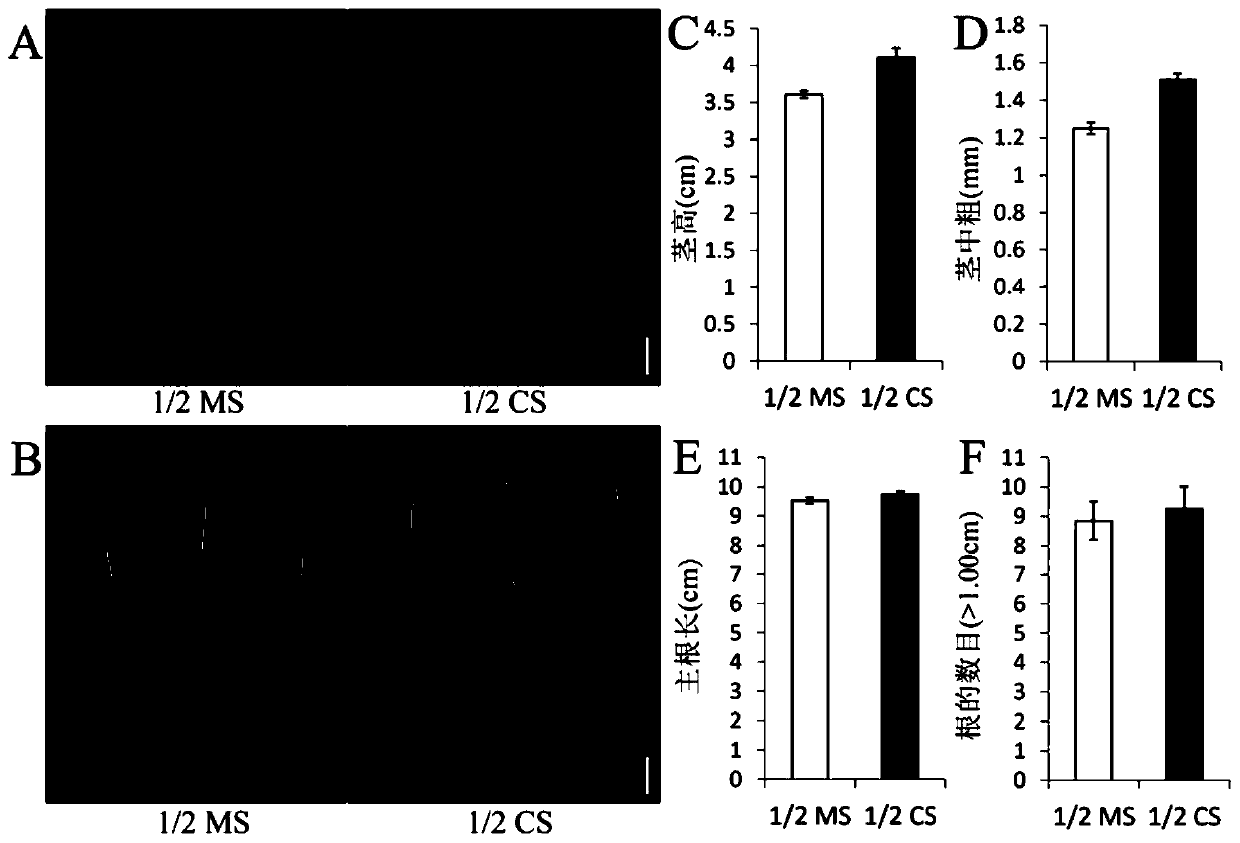

Widely-applicable plant tissue culture medium and 1/2 culture medium

ActiveCN110754366AGood training effectEliminate potential safety hazardsHorticulture methodsPlant tissue cultureBiotechnologyInositol

The invention discloses a widely-applicable plant tissue culture medium and a 1 / 2 culture medium. Each 1000 mL of the culture medium comprises 2662 mg of KNO3, 264 mg of (NH4)2SO4, 288 mg of NH4H2PO4,370 mg of MgSO4.7H2O, 332 mg of CaCI2, 15 mg of MnSO4.H2O, 4 mg of ZnSO4.7H2O, 3 mg of H3BO3, 0.02 mg of CoCl2.6H2O, 0.04 mg of CuSO4.5H2O, 0.1 mg of Na2MoO4.2H2O, 37 mg of NaFeEDTA, 100 mg of inositol, 2 mg of nicotinic acid, 7 mg of thiamine hydrochloride, 1 mg of pyridoxine hydrochloride, and 2 mg of glycine. The content of macro elements is halved to obtain the 1 / 2 CS tissue culture medium. The plant tissue culture medium disclosed by the invention can be widely applied to various plant tissue cultures, the culture effect is equal to or better than that of an MS culture medium, the explosive reagent NH4NO3 contained in the existing culture medium is removed on the premise that new explosive components are not introduced, and the purchase, storage and management of the culture medium are facilitated; moreover, pH stability of a liquid culture medium prepared with the plant tissue culture medium is good.

Owner:SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com