Photosynthetic bacterium with high yield nano-selenium and preparation method of nano-selenium living bacterium preparation thereof

A technology for photosynthetic bacteria and live bacteria preparations, applied in the fields of botanical equipment and methods, microorganism-based methods, biochemical equipment and methods, etc. problems, to achieve the effect of low cost, low equipment requirements, and no three wastes discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

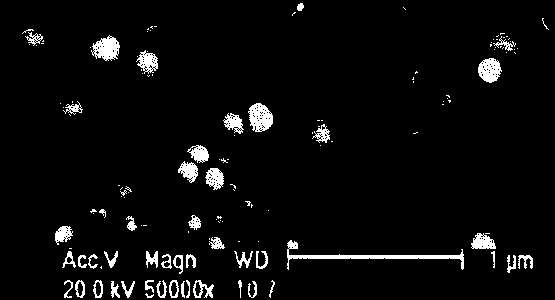

[0035] The screening of embodiment 1 biological nano-selenium producing bacteria

[0036] Preliminary screening: 115 strains of Bacillus, 32 strains of lactic acid bacteria, and 22 strains of photosynthetic bacteria commonly used in the laboratory of the inventor's company were cultivated in a selective medium containing sodium selenite. The red color of the bacterial liquid indicates the presence of nano The production of selenium, preliminary screen out can reduce sodium selenite to produce nano selenium strain.

[0037] The initial screening process is as follows:

[0038] Bacillus: in a sterilized 500 milliliter Erlenmeyer flask, add in the LB liquid culture medium containing 0.5g / L sodium selenite,

[0039] At the same time, according to the 1% (v / v) inoculum amount, the activated bacterial seed solution was added sequentially, and the culture was shaken at 30°C and 180 r / min for 2d-5d.

[0040] Lactic acid bacteria: in 500 milliliters of sterilized Erlenmeyer flasks,...

Embodiment 2

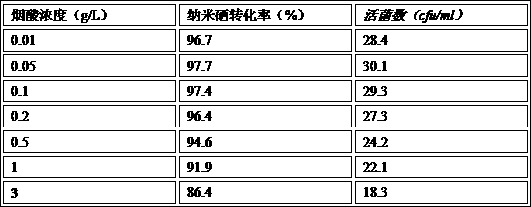

[0049] Embodiment 2 investigates the impact of different concentrations of sodium selenite on JCD-1 bacteria and the conversion rate of nano-selenium

[0050] Investigate the influence of different concentrations of sodium selenite on JCD-1 Sulfur japonica and the conversion rate of nano-selenium, using the photosynthetic bacteria liquid culture medium in Example 1, only changing the concentration of sodium selenite. Selenium content in all samples was determined using flow injection hydride-atomic absorption spectrometry. The culture solution containing the bacteria was taken at 4°C and centrifuged at 10000rpm to measure the selenium content in the supernatant. Conversion rate=(A-B) / A×100%. In the formula, A is the initial selenium content in the photosynthetic bacteria medium; B is the remaining selenium content in the medium after cultivation.

[0051] It can be seen from Table 3 that at a lower concentration (0.5-2g / L), as the concentration of sodium selenite increases, ...

Embodiment 3

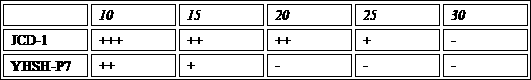

[0053] Embodiment 3 investigates the stability test of different materials to nano selenium of the present invention

[0054] Because our company is in Guangdong area, the part of nano-selenium fermented liquid that produces is in summer, and its room temperature storage is no more than 30 days, just occurs the situation of black selenium, therefore carried out following test, JCD-1 bacterium is in 2g / L sub- After 7 days of fermentation in photosynthetic bacteria medium with sodium selenate (11.567mmol / L) concentration, the conversion rate was detected to be 95.5%, and the number of viable bacteria was 2.95 billion. Take 500mL each and place them in a triangular flask, and add 46.28mmol / L of Various amino acids (partial amino acid solubility is too low, such as tyrosine uses its hydrochloride), niacin, 12g / L soybean protein isolate, 12g / L sucrose, 12g / L milk powder, 12g / L poly grape to adjust pH Up to 7.0, three groups of parallel experiments, in a 45°C incubator (in order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com