Beef cattle heat stress resisting feed additive and using method thereof

A feed additive, anti-heat stress technology, applied in the application, animal feed, animal feed, etc., can solve the problems of different production purposes and uncommon nutrition regulation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

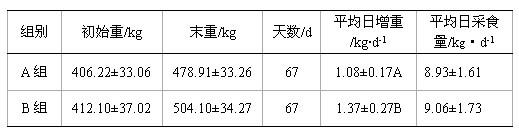

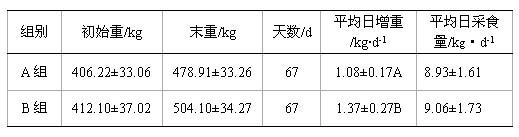

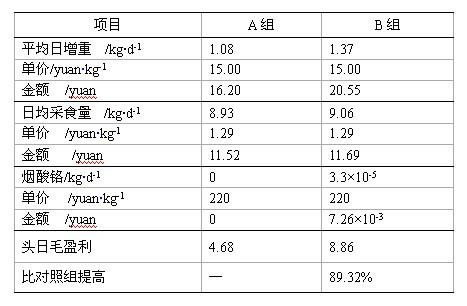

Examples

Embodiment 1

[0011] Composition of anti-heat stress feed additive for beef cattle:

[0012] Chromium nicotinate 5Kg

[0013] Diluent (zeolite powder passed through 80 mesh sieve) 995Kg.

[0014] Preparation method: Accurately weigh 5Kg of chromium nicotinate and 5Kg of 80-mesh zeolite powder in a stainless steel mixer and mix thoroughly (one-time mixing), then add 990Kg of 80-mesh zeolite powder into the mixer Mix again (secondary mixing).

[0015] How to use: Mix this product evenly with the concentrate and feed, and feed 1.65g / head·d per 100kg body weight.

Embodiment 2

[0017] Composition of anti-heat stress feed additive for beef cattle:

[0018] Chromium nicotinate 5Kg

[0019] Thinner (fine stone powder passed through 80 mesh sieve) 995Kg.

[0020] Preparation method: Accurately weigh 5Kg of chromium nicotinate and 5Kg of 80-mesh fine stone powder in a stainless steel mixer and mix thoroughly (one-time mixing), then add 990Kg of 80-mesh fine stone powder into the mixer Mix again (secondary mixing).

[0021] How to use: Mix this product evenly with the concentrate and feed, and feed 1.65g / head·d per 100kg body weight.

Embodiment 3

[0023] Composition of anti-heat stress feed additive for beef cattle:

[0024] Chromium nicotinate 10Kg

[0025] Thinner (starch passed through 80 mesh sieve) 990Kg.

[0026] Preparation method: Accurately weigh 10Kg of chromium nicotinate and 10Kg of 80-mesh starch in a stainless steel mixer and mix thoroughly (one-time mixing), then add 985Kg of 80-mesh starch after mixing, and mix again in the mixer (secondary mixing).

[0027] How to use: Mix this product evenly with the concentrate and feed, and feed 825mg / head·d per 100kg body weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com