Sintered Fe-Al-based alloy porous material and filtering element employing same

A technology of porous material and filter element, applied in the field of filter element and porous material, to achieve the effect of excellent high temperature oxidation resistance, strong alkali corrosion resistance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

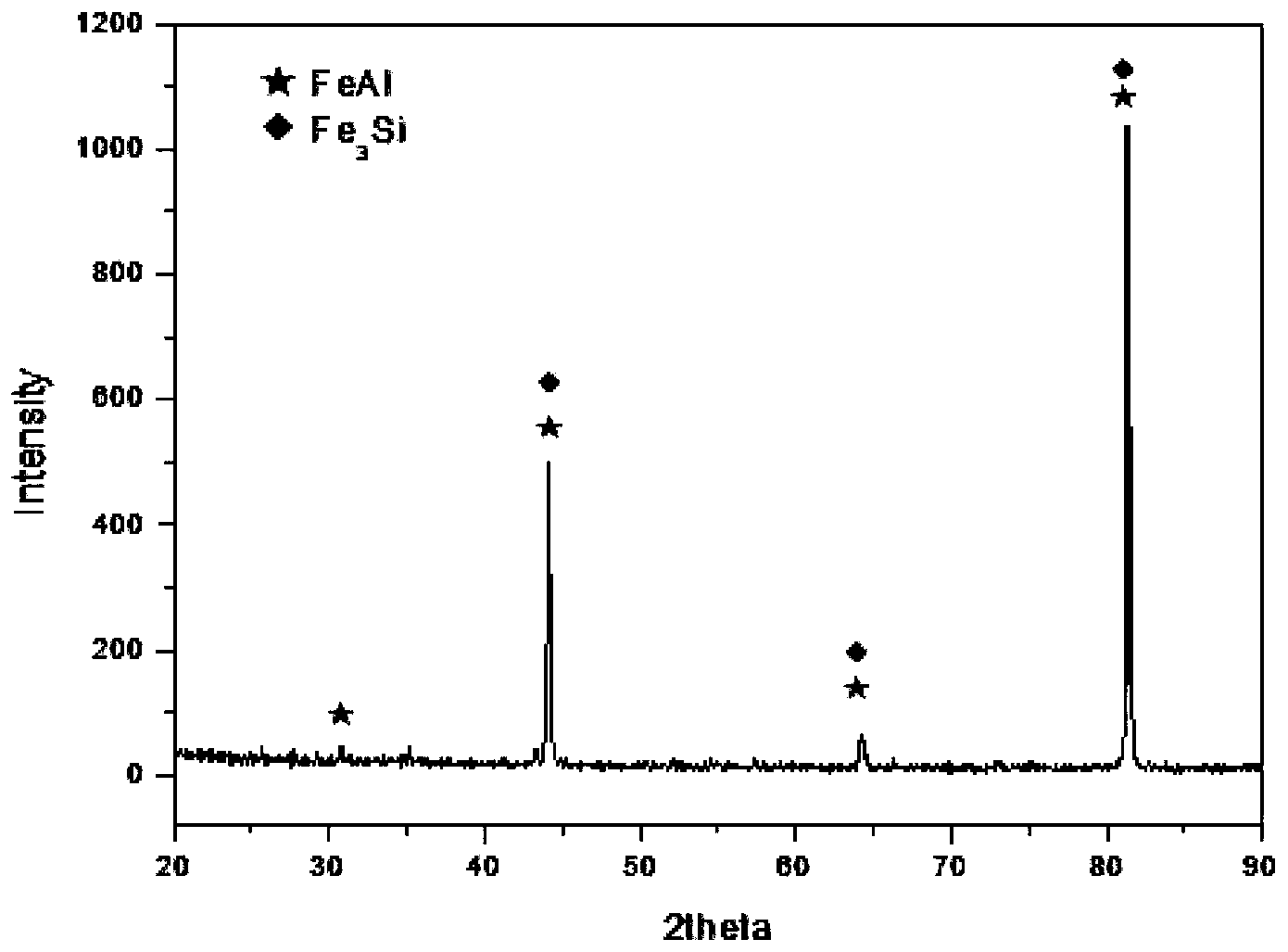

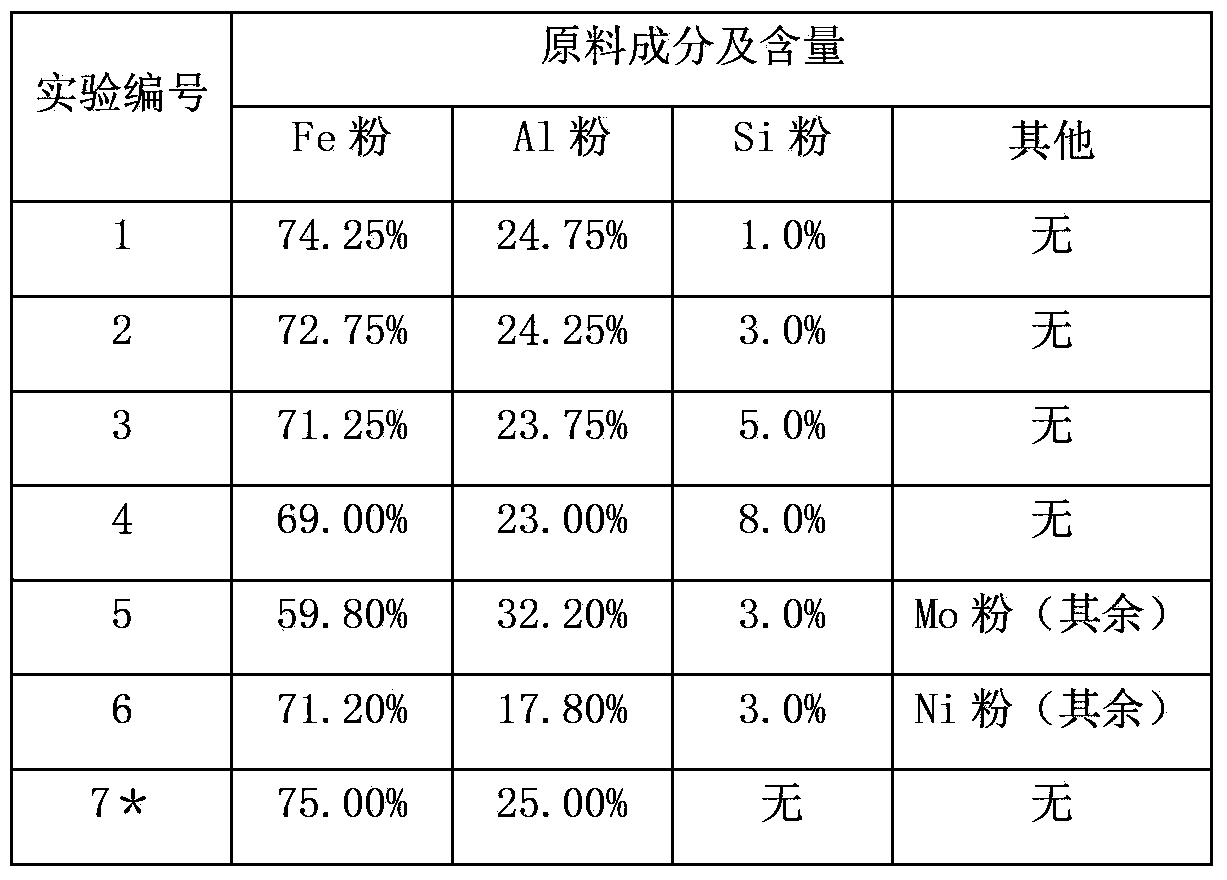

[0024] The preparation method of the sintered Fe-Al-based alloy porous material and the sintered Fe-Al-based alloy porous material obtained by these methods are specifically described below through experiments. Through these descriptions, those skilled in the art can clearly understand the outstanding features of the sintered Fe-Al-based alloy porous material of the present application. The numbers of the experimental examples mentioned below correspond to the numbers corresponding to "green compact" and "sample".

[0025] In order to illustrate the sintered Fe-Al-based alloy porous material of the present application and its preparation, the following 7 experimental examples were prepared. Among them, the samples 1 to 6 respectively prepared by the experimental examples 1 to 6 all belong to the scope of the sintered Fe—Al based alloy porous material to be protected in claim 1 of the present application. Experimental Example 7 is a comparative experiment embodying the substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com