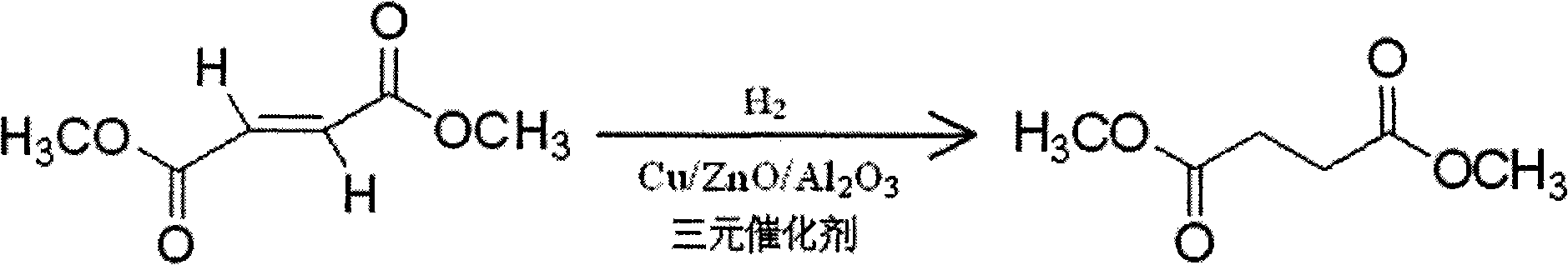

Catalyst for use in synthesis of dimethyl succinate and application thereof

A technology of dimethyl succinate and dimethyl maleate, applied in the field of chemical engineering, can solve the problems of high equipment investment and operating costs and high reaction pressure, and achieves overcoming the high equipment investment and operating costs, Less by-products and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Cu / ZnO / Al 2 o 3 Preparation of -1# catalyst:

[0034] 30g Cu(NO 3 ) 2 ·3H 2 O, 27.66g Zn(NO 3 ) 2 ·6H 2 O, 11.62g Al(NO 3 ) 3 9H 2 O was dissolved in 250ml deionized water to make metal ion solution, 32.3g Na 2 CO 3 Dissolve in 290ml deionized water to obtain a precipitant solution. In a water bath at 60°C, under stirring, the metal ion solution is dropped into the precipitant solution at a certain flow rate to carry out the precipitation reaction, and the pH value of the precipitation reaction is 7.0. After the dropwise addition was completed, the mixture was aged at 60° C. for 1 hour. Afterwards, filter and wash to remove impurity ions, dry at 120°C for 12 hours, and heat up to 450°C in a muffle furnace at 3°C / min for 4 hours. The specific surface area of the catalyst is 101m 2 / g, the average pore diameter is 18.4nm.

[0035] Take the Cu / ZnO / Al prepared above 2 o 3 -1# Granulate to 40~60 mesh, with H 2 After reduction, the / Ar mixed gas is used a...

Embodiment 2

[0036] Example 2: Cu / ZnO / Al 2 o 3 Preparation of -2# catalyst:

[0037] 30g Cu(NO 3 ) 2 ·3H 2 O, 31.35g Zn(NO 3 ) 2 ·6H 2 O, 6.97g Al(NO 3 ) 3 9H 2 O was dissolved in 250ml deionized water to make metal ion solution, 32g Na2 CO 3 Dissolve in 290ml deionized water to obtain a precipitant solution. In a water bath at 60°C, under stirring, the metal ion solution is dropped into the precipitant solution at a certain flow rate to carry out the precipitation reaction, and the pH value of the precipitation reaction is 6.9. After the dropwise addition was completed, the mixture was aged at 60° C. for 1 hour. Afterwards, filter and wash to remove impurity ions, dry at 120°C for 12 hours, and heat up to 450°C at 10°C / min in a muffle furnace for 4 hours. The specific surface area of the catalyst is 89m 2 / g, the average pore diameter is 19.3nm.

[0038] Take the Cu / ZnO / Al prepared above 2 o 3 -2#, the specific steps are the same as in Example 1, the difference is that ...

Embodiment 3

[0039] Embodiment 3: Cu / ZnO / Al 2 o 3 Preparation of -3# catalyst:

[0040] 30g Cu(NO 3 ) 2 ·3H 2 O, 29.55g Zn(NO 3 ) 2 ·6H 2 O, 9.3g Al(NO 3 ) 3 9H 2 O was dissolved in 250ml deionized water to make metal ion solution, 32.3g Na 2 CO 3 Dissolve in 290ml deionized water to obtain a precipitant solution. In a water bath at 70°C, under stirring, the metal ion solution is dropped into the precipitant solution at a certain flow rate to carry out the precipitation reaction, and the pH value of the precipitation reaction is 7.0. After the dropwise addition, it was aged for 45h. After that, filter and wash to remove impurity ions, dry at 120°C for 12 hours, raise the temperature to 450°C at 3°C / min in a muffle furnace and keep it for 4 hours. The specific surface area of the catalyst is 100m 2 / g, the average pore diameter is 20nm.

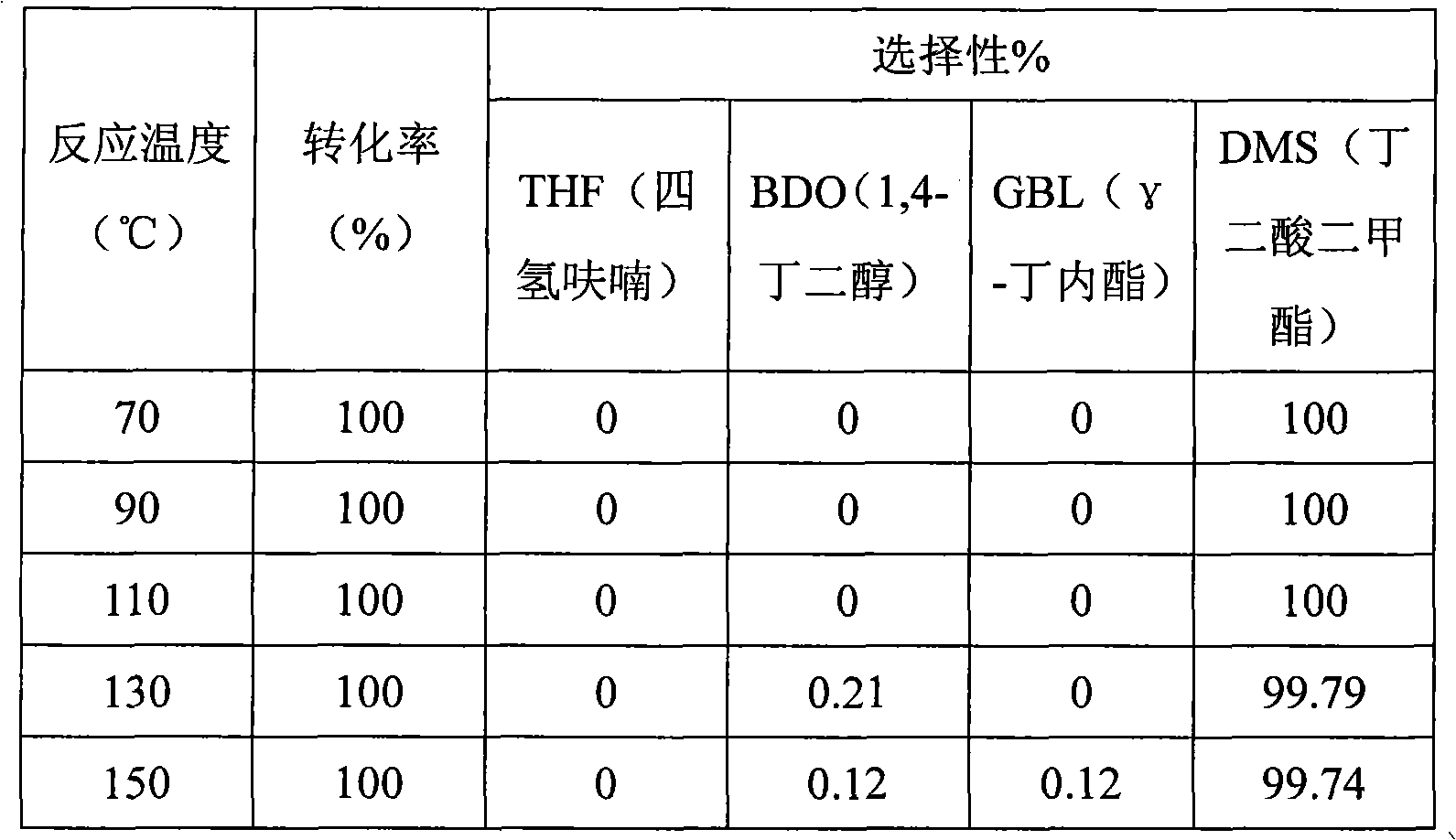

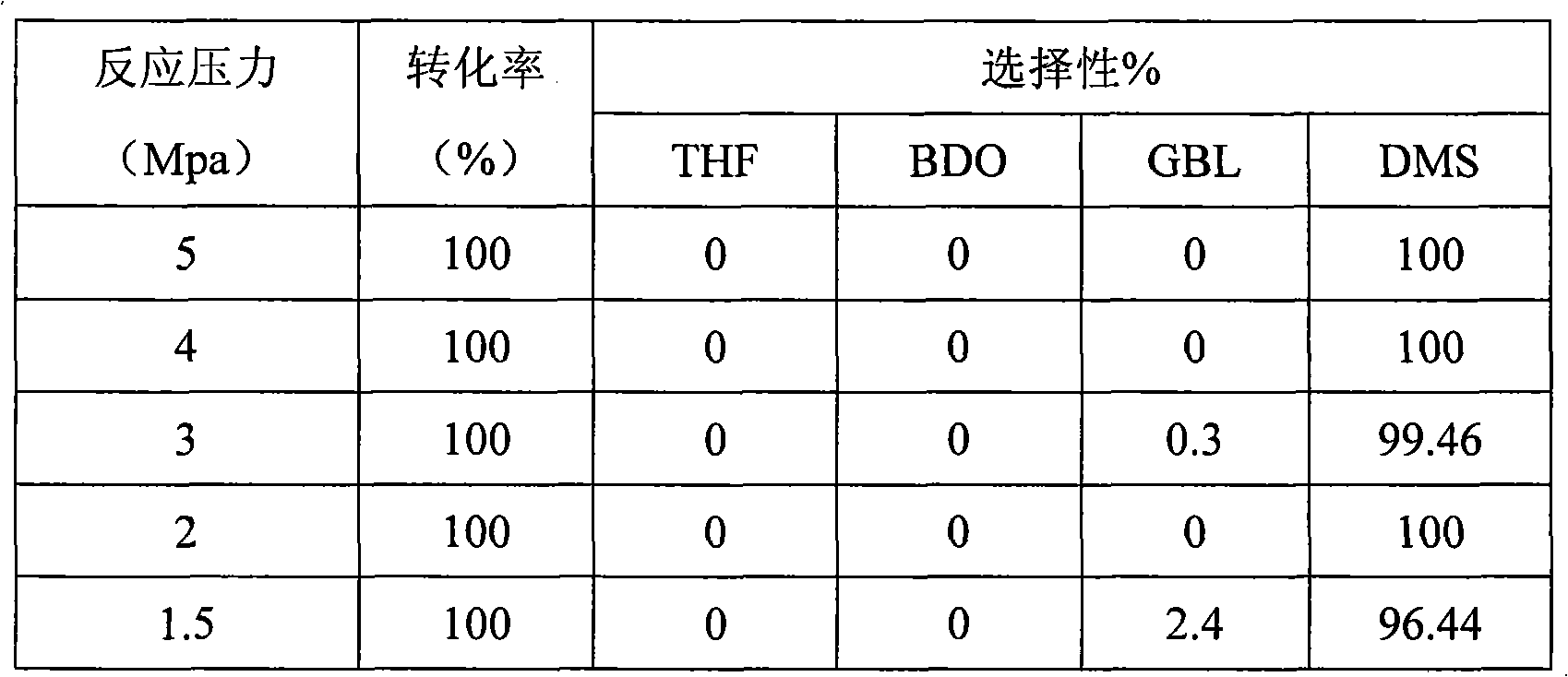

[0041] Synthesis of dimethyl succinate with dimethyl maleate as raw material:

[0042] Take the Cu / ZnO / Al prepared above 2 o 3 -3#, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com