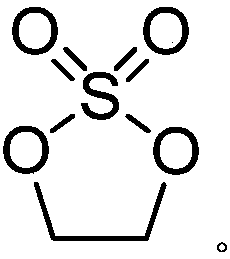

Preparation method of ethylene sulfate

A technology of vinyl sulfate and diethyl sulfate, applied in the field of preparation of vinyl sulfate, can solve problems such as potential safety hazards for operators, unfavorable industrial application, increase post-processing steps, etc., and achieves elimination of potential safety hazards and low production cost. , the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add ethylene glycol (620g, 10mol) and diethyl sulfate (1540g, 10mol) into a 2L three-necked flask connected with a distillation head and a condenser, add lithium hydroxide (1.2g, 0.05mol), and heat to 35°C , adjust the vacuum degree to 50mmHg, and stir until no ethanol flows out. Cool down to room temperature, add methyl tert-butyl ether until a solid precipitates, cool to 0°C, a large amount of solid precipitates, filter, and recrystallize the filter residue with dichloromethane to obtain 669g of vinyl sulfate, the yield is 54%, and the purity is greater than 99% %.

Embodiment 2

[0026] Add ethylene glycol (620g, 10mol) and diethyl sulfate (1617g, 10.5mol) into a 2L three-neck flask connected with a distillation head and a condenser, add sodium methoxide (2.7g, 0.05mol), and heat to 35°C , adjust the vacuum degree to 50mmHg, and stir until no ethanol flows out. Cool down to room temperature, add methyl tert-butyl ether until a solid precipitates, cool to 0°C, a large amount of solid precipitates, filter, and recrystallize the filter residue with dichloromethane to obtain 459 g of vinyl sulfate, the yield is 37%, and the purity is greater than 99 %.

Embodiment 3

[0028] Add ethylene glycol (620g, 10mol) and diethyl sulfate (1617g, 10.5mol) into a 2L three-necked flask connected with a distillation head and a condenser, add lithium hydroxide (0.6g, 0.025mol), and heat to 35 °C, adjust the vacuum degree to 50mmHg, and stir until no ethanol flows out. Cool down to room temperature, add methyl tert-butyl ether until a solid precipitates, cool to 0°C, a large amount of solid precipitates, filter, and recrystallize the filter residue with dichloromethane to obtain 768g of vinyl sulfate, the yield is 62%, and the purity is greater than 99% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com